Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 76 to 90 of 92

-

23rd August 2011, 11:24 AM #76

Just a quick thought Ray.

They are hefty heat sinks so with the prolonged use of the SSRs during a session, will that heat radiating upwards affect the mini PC?

-

23rd August 2011 11:24 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd August 2011, 03:34 PM #77

Hi All,

RC, Of course... I have the same license.

Stuart, You must be going blind , I did edit a few spelling and grammar errors, but that part was always there.. I try to put "EDIT:" when I make a major change to a post. But I wish I had thought to add the tempering furnace to the system earlier. But it only became more obvious how useful it would be after the first couple of trial parts we did. You go from the furnace to quench, then you want to go straight to tempering, but the main furnace is still way to hot, I've been using a modified toaster oven, for now, but that doesn't go to 500-600 C.

, I did edit a few spelling and grammar errors, but that part was always there.. I try to put "EDIT:" when I make a major change to a post. But I wish I had thought to add the tempering furnace to the system earlier. But it only became more obvious how useful it would be after the first couple of trial parts we did. You go from the furnace to quench, then you want to go straight to tempering, but the main furnace is still way to hot, I've been using a modified toaster oven, for now, but that doesn't go to 500-600 C.

Eskimo, Thanks for the vote of confidence... I've spent the last 30 years building stuff for others, (still doing it for that matter) so it's nice to be doing my own boards for a bit of a change.. plus having a few left over bits and pieces is always handy as well.

Auskart, I thought about putting a kw hour meter in there, but as a rough guide, to get up to temperature it generally runs full on at 4.8Kw and 20c per kwh that's about $1 per hour, and to maintain temperature the duty cycle decreases and it drops down to around 50c per hour. I promise to plant a tree for the carbon offset every so often...

NCarcher,

Very good point, during the early trials with these SSR's I measured less than 5 degrees above ambient temperature rise on the heatsink , the CPU board is rated 0-60C, so it's something I'm going to have to keep an eye on, if it looks like getting too hot, I'll have to put a fan in, but I'm expecting that since the enclosure itself is fairly large, there is lots surface cooling and convection should be pretty good.

Regards

Ray

-

25th January 2012, 04:47 PM #78

I finally got the door finished, over engineered as usual

, Stuart thinks I'm suffering from some kind of furnace door affliction...

, Stuart thinks I'm suffering from some kind of furnace door affliction...  he might be right...

he might be right...

It's a parallelogram type action, with a 50 Kg gas strut doing the balancing.

The safety interlock kills the power to the exposed heater elements when the door is opened,

the cable (inside the alumimium tubing) is high temperature rated teflon insulated.

Although I don't expect the shell temperature to get all that hot anyway.

The switch is mounted on standoff's to allow airflow under the switch.

The inside of the door is going to be 1250 C when the furnace is first opened, so it's designed to swing up and away from the operator (me)..

and it's well out of the way making it easy to get tongs inside.

The original stainless work support frame has now been replaced by some ceramic stands (look for "kiln furniture", if you are googling)

Still waiting on ceramic fibre rope door seal to finish off the door sealing.

Almost there..

Regards

Ray

PS... Maybe BT can identify the part in the furnace....

-

25th January 2012, 05:07 PM #79Dave J Guest

Looking good Ray,

Dave

-

25th January 2012, 05:30 PM #80

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

-

25th January 2012, 09:40 PM #81

Hi Stuart,

Since you asked...

[ame=http://www.youtube.com/watch?v=TUkj6Ypd7sM]Heat Treatment Furnace Door Demo - YouTube[/ame]

Regards

Ray

-

25th January 2012, 10:07 PM #82

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

Yes BT can and he's getting excited.

-

25th January 2012, 11:38 PM #83

-

25th January 2012, 11:57 PM #84

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

So it might be out with the files again soon. Make a change from splitting tenths.

BT

-

26th January 2012, 12:11 AM #85

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Well I like the video

Must be the shaper in me lol

Stuart

-

26th January 2012, 06:44 AM #86

Philomath in training

Philomath in training

- Join Date

- Oct 2011

- Location

- Adelaide

- Age

- 59

- Posts

- 3,149

Nice action there. Will you need some extra shielding so that the seals in the gas strut won't cook? A failure there could ruin a whole lot of parts.

Michael

-

26th January 2012, 07:43 AM #87

-

2nd February 2012, 10:37 PM #88

Hi All,

I'm getting close to wrapping this project up, I'm well into the testing phase.

The final thing was the door seals, for which I used 1/2" square section braided rope, that's rated to 1260 C, and I ran two strips, one on the door and another around the edge of the door opening.

Here's the final control enclosure.

The single board PC is a 1.6G pentium Kontron running ubuntu linux with a wifi connection to the local network, and talks modbus rs485 to the temperature controller.

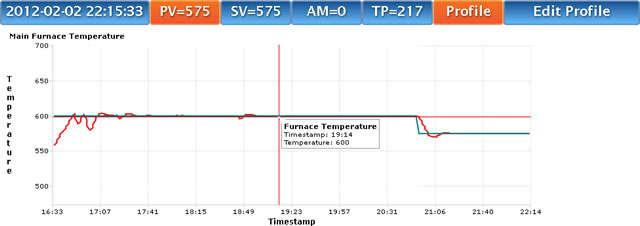

The monitoring and control is via a web browser, which means I can use anything that can access the network and run a browser to watch what's happening. Here is a screen dump

The green line is the set point, the ocscillations at the start is the PID auto-tune being tested... around 18:49 I opened the door, which caused a blip.

and later the set point was dropped by 25 degrees to 575 to see how quickly is would cool, and re-settle.

The TP parameter is the duty cycle, which is scaled 0-1000, so 217 means the heater on time is about 21.7% of the time to maintain 575 C, and

the heaters supply a maximum of 4.8 KW, so to maintain 575, requires just over 1 KW... or about 20 cents per hour..

The job in the furnace at present is a sheet of bronze 600x300 that I want to anneal.

Here's a picture of the inside of the furnace at about 750 C..

The door had been open for about 5-10 minutes before the picture was taken... I was heat treating some O1... you can see the square section door seal around the edge.

Still a bit of work to do with the profile control software, and then I'll be starting on the tempering furnace... which will replace the current toaster oven...

Regards

Ray

PS Josh wants to try cooking a pizza....

EDIT: Michael, I've been keeping an eye on the gas strut, and so far it's stayed at ambient temperature, the outer shell is around 50 C, and probably will go higher on a longer high temperature run.

-

3rd February 2012, 08:16 AM #89

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

-

3rd February 2012, 03:55 PM #90

Fluent Jargon...

The hi temperature pizza ovens usually run out to around 500 F, (260C) With the door closed the furnace was still 270 C after 12 hours cooling from 700 C..

Yes, I posted details earlier, but I used these ones.

The SSR's are from $A5.06ea eBay Australia: Buy new & used fashion, electronics & home d

The SSR heatsinks $A5.73ea eBay Australia: Buy new & used fashion, electronics & home d

They are rated at 25A, and seem to run fairly cool at 10A, the heatsinks haven't gone over 50 C or so.. so far

Regards

Ray

Similar Threads

-

Small Furnace

By Foccacia in forum THE FOUNDRYReplies: 9Last Post: 31st May 2011, 11:24 PM -

Small furnace

By Woodwould in forum METALWORK FORUMReplies: 5Last Post: 12th July 2010, 02:53 PM -

small heat treatment oven

By .RC. in forum METALWORK FORUMReplies: 22Last Post: 25th March 2010, 07:42 PM -

Oil Burners for Casting Furnace.

By impalabazz in forum THE FOUNDRYReplies: 42Last Post: 2nd June 2007, 11:04 AM -

Furnace Filters.

By Caliban in forum WOODWORK - GENERALReplies: 10Last Post: 16th July 2004, 10:36 PM