Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 56

Thread: HM50 Can 'O' worms.....

-

2nd July 2012, 08:49 PM #31Dave J Guest

Hi Ed,

They are not bad mills once you go through them and clean them up and do a few mods. Saying that they will still do the job the way they are, but will work better/smoother and more accurate with a good going through.

Taiwan was probably a good sales pitch as even the next step up in mills are now only Taiwanese heads and Chinese the rest. They used to be all Taiwanese years ago but our importers are cutting costs these days even with the dollar being up, anything for them to make a dollar.

With the quill bearings there are only 2, one tapered at the bottom and one deep groove at the top. If your going to replace them I would recommend doing the conversion I did and change the top quill bearing over to a taper one like in my thread Ewan posted above (and also below). You will need to make a new nut up, but I think the time taken to do that is worth while and so do a few other members that have done it as well.

https://www.woodworkforums.com/f65/ch...e-hm52-126514/

With your noise when doing up the lock a nylon or Delrin sleeve will fix that like I did in the link below (that Ewan also posted above). The problem is once you do up the quill it pushes it out of line making the splines to run on the side of the housing. It also fixes the noise on interrupted cuts from the loose fitting splines.

https://www.woodworkforums.com/f65/an...s-mill-126490/

As for bearings and numbers here is a list I did up a while back for another member, just double check with yours to make sure, but they should be the same.

The manual can be found in the link below which is a grizzly one, and while there are some slight differences in things like the quill down feed, it's basically the same machine.

http://cdn0.grizzly.com/manuals/g3617_m.pdf

I have added the prices I got from my local SKF bearing place for you to compare with others.

Top quill bearing is a 6009-2RS deep groove (replaced with a taper 32009X/Q x1) = $16.52

Bottom quill bearing is a 32010-X/Q x1 = $16.73

Quill pulley 6009-2RS x 2 (x2) =$28.51

Idler pulley 6003-2Z/C3 x 2 (or if doing the horizontal as well x 4) (x 4) = $15.05

Down feed worm shaft 6002-2RSH x 2 = $8.21

Motor 6205-2RSH x 2 (or if doing the horizontal as well x 4) (x 4) = $20.59

These are not needed for yours but I will leave them up for others with a HM52.

Horizontal front 32011-X/Q x 1 = $25.55

Horizontal rear 30308-J2/Q x1 =$24.39

Horizontal 2nd idler 6005-2Z x 2 (x 2) = $9.11

Total is $147.93 which is not bad for every bearing in the machine.

For taking the quill apart I also wrote this up a while back

I am not sure if yours has it (my old mill didn't) but if you have a machined groove down the left hand side of the quill (extend it and have a look) to stop it rotating you need to remove the 2 screws holding the alignment pin on the left hand side.

Lock up the quill lock.

Place a block of wood on the table between the quill and table, wind the knee up until the block touches the quill to stop it dropping when it is released.

Undo the chrome cover on the left hand side of the head that covers the quill spring return. Under this there is a round cast iron piece that the spring sits in. Under the left hand side of the head their is a small screw or grub screw, undoing this will release the collar but be careful as it is tensioned to keep the quill up (wear a glove) it will want to spin round about 1 turn. The collar has a few holes around the outer edge were you can put a small screw driver or something to stop it for rotating, they are also helpful for tensioning it when you reassemble.

Undo the 3 bolts on the right hand side of the head that hold the quill handle/fine feed to the head and slide the whole lot out.

Remove the quill lock the wind the knee down to with draw the quill from the housing.Be careful as it has a bit of weight in it.

Once you have it out you will see on the top of the quill there is 1 or 2 nuts that have a metal tab under them that is bent up, just bend these down and undo the nuts.After that you need to press the quill out of its housing. I found that a soft face hammer worked and it came out without much trouble.

There is a plain bearing on top and a taper bearing like a car wheel bearing on the bottom.

I also went through the spindle pulley bearings at the front of the head as they were a bit rough sounding as well. They are not part of the spindle, the only connection is with the quill spline, that runs through the middle of it.

Dave

-

2nd July 2012 08:49 PM # ADSGoogle Adsense Advertisement

-

2nd July 2012, 10:48 PM #32

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- Melbourne

- Posts

- 2,951

Thanks Ed,

Well I woke up this morning with a fever of 40.5 deg. Been feeling like I'm gunna die! The GW has been looking after me bless her soul!

Tomorrow's another day.......

Simon

-

2nd July 2012, 11:01 PM #33Dave J Guest

I sorry to hear you and your family are crook. The flu went around up here a few weeks back and lasted about a week and then another week getting over it. The nieces kids have had a vomiting virus, but they can keep that one to themselves, LOL

Get well soon so we can see your updates on your mill,

Dave

-

3rd July 2012, 06:43 AM #34

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

-

3rd July 2012, 04:16 PM #35

Novice

Novice

- Join Date

- Jun 2012

- Location

- Rye,Vic, Australia

- Posts

- 19

G'day all

David, thanks for the heads up and prices, big help though the timing is a little out now. Darn cars and 120'000km service $868.00 bucks later thank you very much .

.

After Ueee gave me all those links, I started trolling through all the mods, info and video's (who needs sleep and youtube is a bottomless minefield). So after all that, I need to machine a grove, make a new nut and go buy some bearings. Thanks, that's all I need to keep me busy for a while. I was thinking to machine the grove (no horizontal), I may be able to do it on my lathe, something for me to chew on for a while.

Thanks, that's all I need to keep me busy for a while. I was thinking to machine the grove (no horizontal), I may be able to do it on my lathe, something for me to chew on for a while.

Simon, we got a tropical fish tank here at home. You could come take a dip to lower your temp and I could unplug the heaters for a while to lower our carbon footprint. It's a win win

Ed

-

3rd July 2012, 08:07 PM #36Dave J Guest

Hi Ed,

The slot is not really a big deal, the main thing it's good for is when I fitted a glass scale to the quill I no longer needed my bracket to stop it rotating slightly as the glass wont allow much.

Dave

-

3rd July 2012, 09:08 PM #37

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- Melbourne

- Posts

- 2,951

Thanks Ed. I was actually waiting for phil to come and tuck me in!

Since mill is still apart I had to do some basic milling on my lathe. What a PITA that is. I can't believe I was going to purchase a milling attachment for the lathe inleu of a proper (well should I say a form of) mill.

Simon

-

4th July 2012, 07:27 PM #38

Novice

Novice

- Join Date

- Jun 2012

- Location

- Rye,Vic, Australia

- Posts

- 19

Dave; What the heck is a "glass scale to the quill"??? Is it a half empty, or half full glass of red and did you add a shelf to the quill to sit it on???

Simon; I have looked at how I could/would mill on the lathe and agree, it looks to be a bit of a pain. On the other hand, even if I have to buy some gear, I think it will still be cheaper than getting someone else to do it for me. Bonus is, I get to go shopping and get more gear (not that I can afford it or have any other use for it).

Ed

-

4th July 2012, 10:15 PM #39

I think Dave drink Coke in the shed......

He means a DRO scale, like this: Q659 | 70-659 Vertical Digital Scale | machineryhouse.com.au1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

4th July 2012, 10:23 PM #40

A glass scale is a bit different to that one

D719 | GS30 Easson DRO Scales | machineryhouse.com.au

-

4th July 2012, 10:24 PM #41

Hi,

The table is back on now, damn there is actually some weight in the thing! I had no helper today to lift it with me and the place is too much of a mess for me to think about pulling the crane out.......what do they say about young and dumb???

I got the leadscrew back in, only to find it binding at one end still . The opposite end to where i measured the height of the nut from. To be expected i guess but the ends of the table were not pinned on at the same height

. The opposite end to where i measured the height of the nut from. To be expected i guess but the ends of the table were not pinned on at the same height . So now one end has no pins, it looks to be lower than it was by .5mm or so. With the nut split and all the muck cleaned out i know have very minimal backlash-.1 or so, much better than the .4 i had.

. So now one end has no pins, it looks to be lower than it was by .5mm or so. With the nut split and all the muck cleaned out i know have very minimal backlash-.1 or so, much better than the .4 i had.

I also got the rubber on behind the table, it is still a bit long at this stage but i will live with it for a while and see how it goes. I ended up making it 440mm wide. This looks to be the widest i can go with any coolant running off it still being caught by the tray.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

5th July 2012, 12:59 AM #42Dave J Guest

Sorry ED, I was meaning a digital readout glass scale like Fred posted. When I bought my DRO I bought 4 scales as one was for the quill.

With these glass scales they don't recommend much (if any) movement in any direction, so the quill slot helps to stop any rotation.

With the mill before this without a quill slot I had a 22x22mm square bar vertical off a collar on the quill with 2 rubbing blocks to stop any rotation.

Dave

-

5th July 2012, 01:00 AM #43Dave J Guest

Nice job Ewan,

you have done it pretty well identical to what I did mine.

you have done it pretty well identical to what I did mine.

Dave

-

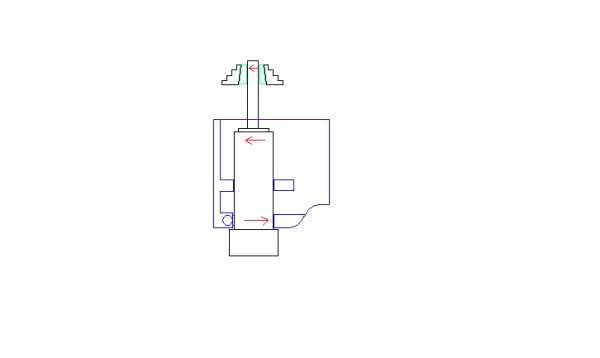

5th July 2012, 01:08 AM #44Dave J Guest

-

6th July 2012, 07:19 PM #45

Novice

Novice

- Join Date

- Jun 2012

- Location

- Rye,Vic, Australia

- Posts

- 19

Similar Threads

-

HM50/52 Y way covers

By Ueee in forum METALWORK FORUMReplies: 6Last Post: 22nd June 2012, 09:36 PM -

Worms

By Calm in forum WOODIES JOKESReplies: 3Last Post: 19th June 2010, 07:23 PM -

worms in cedar

By ralphtaff in forum WOODTURNING - GENERALReplies: 14Last Post: 25th February 2009, 05:20 PM -

Can of Worms

By Felder in forum WOODIES JOKESReplies: 0Last Post: 13th April 2007, 10:54 AM

Likes:

Likes: