Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 75 of 279

Thread: Scraping Projects

-

21st November 2011, 06:44 PM #61

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Found it.

Home Machine Shop

But it came from here like you said Phil.

Qualitative flatness testing, cheap. (pics) - The Home Shop Machinist & Machinist's Workshop Magazine's BBS

Havent read the thread fully yet.

Stuart

-

21st November 2011 06:44 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

21st November 2011, 06:51 PM #62

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jul 2011

- Location

- Melbourne Australia

- Posts

- 1,128

-

21st November 2011, 07:10 PM #63

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

I just go by my plate spec sheet....

Light red, the colour of choice for the discerning man.

Light red, the colour of choice for the discerning man.

-

21st November 2011, 08:09 PM #64

Not flat enough....

Not flat enough....

Regards

Ray

-

21st November 2011, 08:27 PM #65

Doen't look like it's be de-purred yet ......

-

21st November 2011, 08:33 PM #66

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Can I scrape that one for you Richard

-

21st November 2011, 08:53 PM #67

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

OK, I linked to the wrong picture...

Light red, the colour of choice for the discerning man.

Light red, the colour of choice for the discerning man.

-

21st November 2011, 09:01 PM #68

-

21st November 2011, 09:08 PM #69

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Lol thanks Ray

-

21st November 2011, 10:05 PM #70

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Stuart I read through the 2 threads and I'm just trying to work out what the point of it is? The OP said in his initial post:

So he spotted his mill table off a surface plate, hardly earth shattering! ... however knowing the poster as I do, I'm sure he'd claim his POS Chinese plate was actually accurate to 1/2 a nanometerI had a lot of questions about how I managed to get the mill table that I just anodized as flat as it is. I won't go into all the details but it's a matter of a lot of careful work and comparing to a known accurate reference such as a surface plate the old fashioned way with layout dye. I use acrylic artist paint.

Anyway I digress, it seems his method isn't really too helpful once getting down as flat as a surface plate, so say the whiz-bang 5 angstrom laser lever he picked up from Harbor Freight for a buck-ninety-nine says the surface "isn't" flat, then what? Throw it on a surface plate, spot it, and scrape it in? Why not just throw it on a surface plate and spot it to begin with? Use the laser to annoy the neighbours

Pete

-

22nd November 2011, 12:03 AM #71

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi RC

Nice DTI, my 1um Mitutoyo is 0.2mm a turn. I paid $40 for it but it wasnt new, didnt even have a contact point.

Hi Pete,

Yeah I'd dismissed all the ummm "stuff" about the mill table(the paint would seem to be a pretty painful idea, but it would teach you to stay clean).

I think the method could show if there was a shocking error(but could you really be sure? if it was bad enough it wouldnt show up). Of course as the blocks got bigger the set up would become even more fiddily. Maybe as you say I've missed the whole point of his idea.

I'm still trying to get my head around local low spots.

Stuart

-

22nd November 2011, 02:45 AM #72

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Hey Stuart, if so I guess that makes a few of us that have missed the point ... or on the other hand have concluded there was no point

The method seems fine in theory, the reflected beam will be finer as the surface perfection approaches total flatness, and maybe it is indeed a valid way to confirm a very large area is indeed "flat". I don't know, and I haven't seen evidence of anyone else trying and confirming the results. Unfortunately the author of that piece comes up with some absolutely brilliant work. He also comes up with complete BS. It's normally impossible to tell the difference, and the ratio seems about 1:10

The method seems fine in theory, the reflected beam will be finer as the surface perfection approaches total flatness, and maybe it is indeed a valid way to confirm a very large area is indeed "flat". I don't know, and I haven't seen evidence of anyone else trying and confirming the results. Unfortunately the author of that piece comes up with some absolutely brilliant work. He also comes up with complete BS. It's normally impossible to tell the difference, and the ratio seems about 1:10

Pete

-

22nd November 2011, 08:01 PM #73

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

Had a play with my Tesa indicator this evening.... My god a micron is a small thing....

Light red, the colour of choice for the discerning man.

-

22nd November 2011, 08:36 PM #74

I read most of that thread on laser measuring of flatness, and it's mostly BS, with a smattering of good idea thrown in...

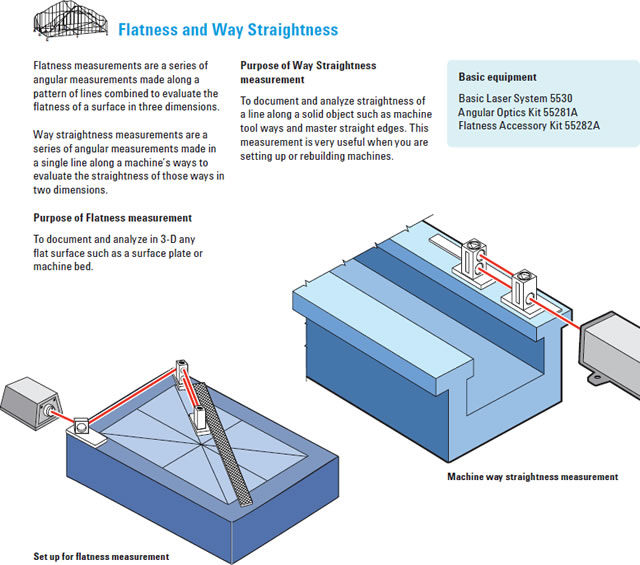

The "traditional" method of laser measurement, is using a laser interferometer, where you detect the reflected beam interference patterns with the incident beam, you can get down to fractions of a nano-meter ( thousandths of a micron) There are some systems that will do real-time nanometer accuracy CMM calibration, like the HP (Agilent) 5530 Dynamic Calibrator which will do 1 nm resolution for machine tool alignment... but it's a good deal more expensive than a Harbour Freight laser pointer..

I'm not completely dismissing the idea that there might be a clever way of using a cheap laser pointer to measure flatness, but (to my mind) that ain't it.

Regards

Ray

I see low cost laser interferometer bits and pieces on ebay, but unless you know exactly what the parts are for, it would be a waste of money. But given the rate at which this stuff becomes obsolete, it might be worth keeping a watch..

EDIT: Here is the setup for flatness measurement with an Agilent 5530 Laser Interferometer. (resolution 0.25nm NIST traceable )

Not sure I need one, but I want one....

-

22nd November 2011, 08:48 PM #75

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

I've been looking at RC's certificate, and now that I've figured out that O is not zero, but maybe Origin, it makes more sense. Would be less confusing to omit the O. Anyway, I'm wondering how they do these surveys.

I actually went looking recently for a cheap way of surveying a surface at these levels of sensitivity. I figured there must by now be a software and hardware combo that could do this for about $1.99. Not so. I found photogrametry but I don't think it's sensitive enough. There are surface contact probes but they're big bucks on their own, before you plug them into anything. That's when I gave up. I bet Mr Chong just has a simple repeatometer.

Edit: Ray, that is way cool.

Similar Threads

-

Scraping.

By derekcohen in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 5Last Post: 26th July 2011, 09:10 PM -

Scraping practice

By jhovel in forum METALWORK FORUMReplies: 7Last Post: 11th July 2011, 07:01 PM -

Scraping

By wheelie in forum WOODTURNING - GENERALReplies: 8Last Post: 23rd September 2006, 09:40 AM -

Scraping

By 9Fingers in forum WOODWORK - GENERALReplies: 22Last Post: 28th January 2006, 04:32 AM

Likes:

Likes: