Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 13 of 13

Thread: Shaper tool head questions

-

30th May 2012, 11:40 PM #1

Shaper tool head questions

Shaper tool head questions

Hi,

I just have a couple of questions about the tool heads on your shapers.

Firstly, Do any of your machines have locks on the dovetails?

When we pulled Freddie apart there was a block bolted on with one of the rotating bolts(see pic) I didn't think twice about it then (actually i didn't even remove it, my mate did, i was at the other end wrestling the motor and gearbox) but coming to re-assemble tonight, i realized it was a lock. The bolt in the side pushes on a brass lug which pushes the sliding part of the head onto the dovetail. I wonder if this is ok, as unlike most dovetail slide locks, it is not pushing on the gib, it is pushing one side into the dovetail and one side out of the dovetail. Do you think this will be o.k?

Secondly, Is you graduated collar moveable, or fixed on the shaft? Mine is fixed which seems a bit strange, it would be a bit hard to zero like this! i think i know the answer to this one already but i thought i'd check.

Thanks in advance1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

30th May 2012 11:40 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

31st May 2012, 01:36 AM #2Dave J Guest

I don't think the lock would worry anything, if the gibs are firm it wont move much and will only go side ways if it does which wont affect height.

With the graduated collar, as far as I know they should all turn, are you sure it's not just stuck?

Dave

-

31st May 2012, 02:10 AM #3

Thanks Dave,

The collar is pinned onto the handwheel.......no chance at all its stuck! There has been some dodgy work done in that area though, so as i thought i'll have to fix it up. I can ask JBoogie on PM for some pics of his.

I was more worried about the rigidness of the head, if only one side of the dovetail is tight, the smallest amount off chatter may be started, Does the Alba have a lock?1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

31st May 2012, 02:15 AM #4Dave J Guest

Been a while since I looked, but I think it uses one of the gib screws to lock it.

I will double check tomorrow as the Douglas set up keeps running through my head because thats what I am into at the moment, LOL

Dave

-

31st May 2012, 09:37 AM #5

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

-

31st May 2012, 10:16 AM #6

Thanks Bryan,

I knew there was another question I was going to ask last night but I couldn't think of it.

What's the best thing to lube the bull gear with? Grease or oil?1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

31st May 2012, 10:40 AM #7

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Grease is a Bad Idea for open gears with chips everywhere. I've rigged a drain from one of my ram ways to drip on the bull gear. Didn't seem to be any provision originally. I just checked the manual and the bull gear is not even mentioned in the lubrication chart.

-

31st May 2012, 10:15 PM #8

I should have called this thread "General shaper questions"

This is one for those who have square knee rise and fall guides.

I put the knee on today, but when i do the bolts on the rear part of the guide's up it clamps the knee onto the guides. I need to shim at least 6-8thou to get anything like a nice fit, could it be possible that the guides need to be loosened to move the table? Seems like a real pain to me, 5 bolts each side, but if not why so tight, there were no shims when we pulled it apart.1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

31st May 2012, 10:19 PM #9

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Same here. I had to leave one way plate slightly loose. I don't know why either.

-

31st May 2012, 10:44 PM #10

Thanks Bryan,

I didn't even realize, i just did them up and then tried to move the knee......I'm just worried about table sag whilst setting up, there is alot of weight hanging of the front of the knee. I'll have a shim session and see how i go. If i had a surface grinder i would knock a few thou off the way plates (thanks for the name, i wasn't quite sure off what to call them)1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

31st May 2012, 10:49 PM #11

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

At the risk of being stoned. You are meant to do your vertical tool movement with the tool slide not the table. You wouldnt want the table moving back and forward with the ram.

Having said that...... with the cuts most of us are going..I leave mine "not to tight". I dont even have a table support.

The collar on my shaper is movable. not lock on the slide, though I do wonder about the backlash in the nut making the cut pull deeper...still its the same as a lathe cross silde....

Stuart

-

31st May 2012, 10:53 PM #12

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

1st June 2012, 04:42 PM #13

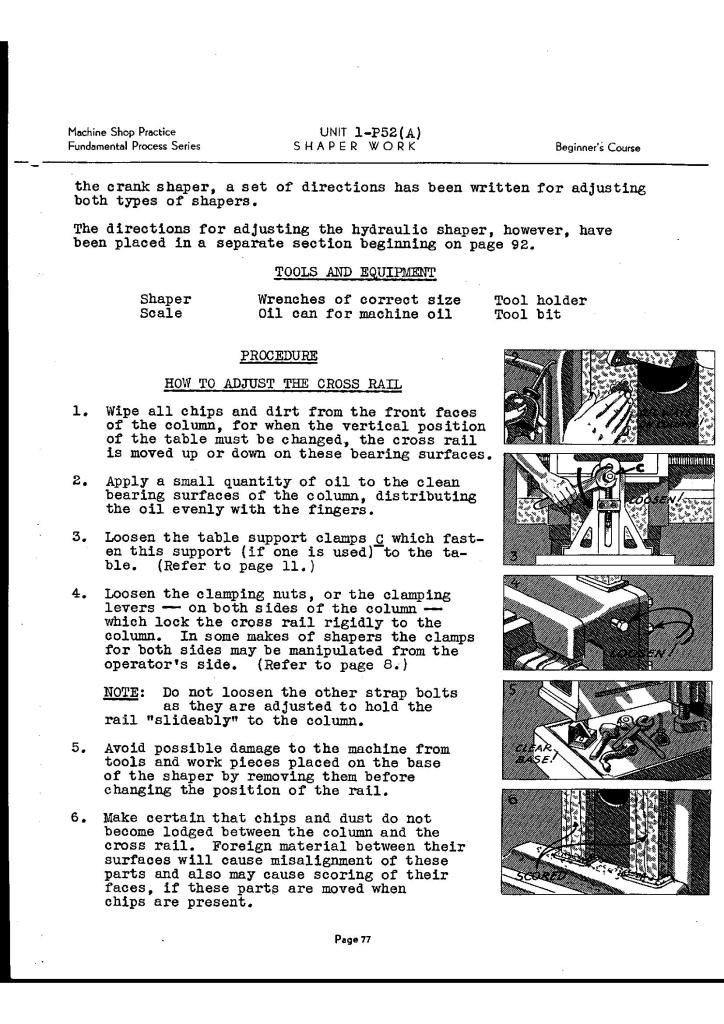

Hi Bryan,

I found this reference to loosening the way plates "locking bolts" It is from the "Suggested unit course in Shaper Work for beginners in machine shop practice" from 1944.

The link to all 57 meg of it is here: http://www.airgraver.com/shaper/shapers.pdf1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

Similar Threads

-

shaper tool bits

By morrisman in forum METALWORK FORUMReplies: 7Last Post: 7th February 2012, 09:09 PM -

Shaper shear tool for finishing

By .RC. in forum METALWORK FORUMReplies: 3Last Post: 26th December 2011, 10:06 PM -

Mini Max Lab30 Shaper/Moulder Head knives/blades

By shedfriend in forum TABLE SAWS & COMBINATIONSReplies: 8Last Post: 21st May 2011, 03:32 AM -

Lathe tool questions.

By JDarvall in forum WOODTURNING - GENERALReplies: 14Last Post: 10th March 2007, 11:53 AM -

another tool questions

By lubbing5cherubs in forum WOODTURNING - GENERALReplies: 15Last Post: 15th December 2006, 12:48 AM