Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 20

Thread: Threading with no chase dial !

-

18th March 2012, 04:59 PM #1

Threading with no chase dial !

Threading with no chase dial !

Hi

Been reading up on how this Hendey lathe cuts threads without a chasing dial .

Easiest thing is to scan 2 pages from the manual

Looks like the lead screw drive mechanism has 3 positions ..forward neutral and reverse . The lower shaft has stops on it , the stops disengage the lead screw feed mechanism and knock it out of drive . When thread cutting , you simply use a lever just below the carriage and reverse the carriage direction .

MIKE

-

18th March 2012 04:59 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

18th March 2012, 06:09 PM #2

Hi Mike,

I have a chase dial, but don't use it, just reversing each time is a pretty standard way of doing it.

Does your have the quick retract mechanism?

Regards

Ray

-

18th March 2012, 06:33 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2011

- Location

- Australia east coast

- Age

- 71

- Posts

- 1,469

Single tooth dog clutch in the drive train, exactly the same as my Monarch. It works for power feeds too (at least mine does) so you can set it for turning to a shoulder or blind inside bore and no longer sweat over a crash. I love it, that & the taper attachment was why I bought the lathe. Well, the ability to peel metal off fast didn't hurt either.

You're going to love that Hendey once you have it sorted.

PDW

-

18th March 2012, 08:01 PM #4

Well now, this is very interesting. I've always wondered hot the clutch worked in the head of mu Conrik, and always thought i was missing some parts, but until seeing Mikes book with the Hendey reverser pictured i never new. What do you guys think? Not sure about a "path" for the control arm, but i'll have to look under the head.

This mystery part also came in the box of bits with the lathe. Now i can look at it in a new light and see if it fits anywhere.

Ewan

-

18th March 2012, 08:31 PM #5

Turning useful pieces of steel into scrap metal.

Turning useful pieces of steel into scrap metal.

- Join Date

- Jun 2010

- Location

- Riverina, NSW, Australia

- Age

- 68

- Posts

- 134

-

18th March 2012, 08:47 PM #6

-

18th March 2012, 08:57 PM #7

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Ewan,

If its a single toothed clutch and it turns 1:1 with the spindle, I'd say you have a winner.

Stuart

-

18th March 2012, 11:00 PM #8

Turning useful pieces of steel into scrap metal.

Turning useful pieces of steel into scrap metal.

- Join Date

- Jun 2010

- Location

- Riverina, NSW, Australia

- Age

- 68

- Posts

- 134

-

19th March 2012, 06:49 PM #9

Senior Member

Senior Member

- Join Date

- Apr 2008

- Location

- NSW

- Posts

- 356

A modern lathe with a foot brake does not need a chasing dial and you don't disengauge the half nuts until the thread is finished . Just hit the foot brake at the end of the thread and the lathe stops dead . If you want to cut up to a shoulder without a relief cut then withdraw the tool as you brake. With a relief cut , after braking , withdraw the tool move the stop start lever to reverse and reverse out to the start then reset tool depth and go forward. For an instant reversing 3 phase motor you don't need a foot brake just slam it into reverse as you back out the tool but it does not always stop as dead on as using a foot brake.

The volume of a pizza of thickness 'a' and radius 'z' is given by pi z z a.

-

19th March 2012, 07:37 PM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2011

- Location

- Australia east coast

- Age

- 71

- Posts

- 1,469

Try that threading a blind internal bore something like 4 tpi at 120 rpm. Let me know how you get on....

Also put on a fine feed on a long cut and bugger off to do something else. Get distracted and see how you go.

I've used a modern lathe with foot operated spindle brake. Give me my Monarch single tooth dog clutch any day.

PDW

-

19th March 2012, 08:12 PM #11

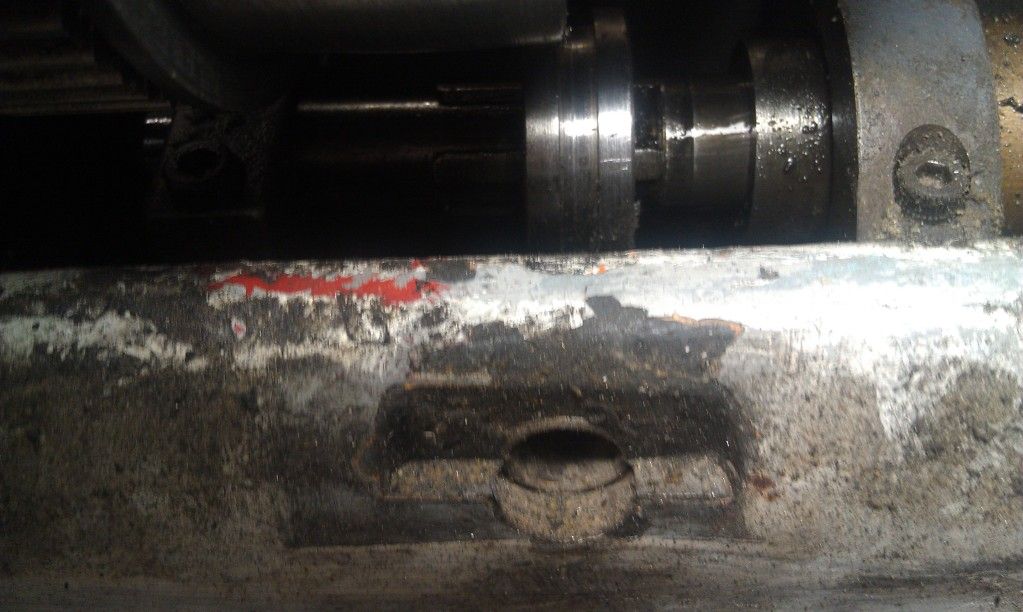

I found some pics on PM of a guy who rebuilt a cone head hendey. I was amazed to see how simple the dog clutch is. Not really 2 mating parts like a "typical" toothed dog clutch, Just a "tooth" on each face, so the clutch has positive drive in either direction but about 3/4 of a turn play. Here was me expecting a single tapered tooth and a mating part. I guess the idea of having so much play is for ease of engagement.

Can the Hendey and Monarchs clutch's be engaged whilst the machine is turning?

As i said i am missing parts from my lathe, if it did have a reverse and clutch mechanism like the Hendey then all 3 gears and both clutches are gone. What you see is what i got.

Ewan

-

19th March 2012, 08:21 PM #12

-

19th March 2012, 08:27 PM #13

Mike,

I've just trawled through my history and found the PM thread. The pic of the clutch is about half way down. Hendey 14 by 6 Tie-Bar Rehab - Page 2

Ewan

-

19th March 2012, 08:35 PM #14

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2011

- Location

- Australia east coast

- Age

- 71

- Posts

- 1,469

Most certainly can. There's an upper speed limit because things will go 'crunch' in a not nice way, but my std practice is to engage, let the feed happen until the stop cams the clutch out, back out the tool then if threading, reverse using the apron lever. If turning, I manually wind back the carriage and then re-engage. If threading you need a run-out groove if you're not going to be paying attention & back the tool out.

The only thing I'd really like is rapid feeds to get back for the next cut as some of the modern machines have. I've never seen one with rapids and a single tooth dog clutch, but no doubt they exist.

PDW

-

19th March 2012, 08:36 PM #15

Philomath in training

Philomath in training

- Join Date

- Oct 2011

- Location

- Adelaide

- Age

- 59

- Posts

- 3,149

I don't know about a Hendy but a CVA can engage the clutch while going (although it is suggested not to do this at high revs - although I normally thread around 80rpm and this is fine). I'd guess that means a Monarch can too.

Michael

Attachment 201922

Similar Threads

-

The Chase

By joe greiner in forum WOODIES JOKESReplies: 0Last Post: 6th June 2008, 11:55 PM -

Car Chase

By wheelinround in forum MOTOR VEHICLESReplies: 28Last Post: 23rd October 2007, 07:02 PM -

chase lounge dimentions???

By brian mcmillan in forum WOODWORK - GENERALReplies: 3Last Post: 27th September 2007, 10:01 PM