Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 136 to 150 of 171

Thread: Varnamo Shaper

-

16th December 2011, 10:49 PM #136

Hi Stuart,

Yes, right again, hitting part 62 makes more sense, and from the shape it looks like the handle at the back drops it down to disengage the downfeed.

Regards

Ray

3 roller ratchets.. and counting

PS: I've edited the drawing, you might have to hit shift reload to get the later version..

-

16th December 2011 10:49 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

16th December 2011, 11:13 PM #137Dave J Guest

Those one way bearings have come down in price over the years

One Way Bearings & Clutches eramic,Miniature Ball Bearings

eramic,Miniature Ball Bearings

Might be an easier idea if your going to go through with it.

Dave

-

16th December 2011, 11:15 PM #138

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 59

- Posts

- 2,557

Ray I was talking out of my hat. Mine has only one nut. It is stationary when hand fed and rotates under power.

-

16th December 2011, 11:20 PM #139

The site i've been working on the last few days has a similar roller type setup to stop pumps (Big Caprari Turbines) from rotating backwards, full load current 435 Amps, when we were commissioning, one of them was wired for reverse rotation... never seen a danfoss drive shut down so quick...

No smoke either...

Regards

Ray

-

16th December 2011, 11:44 PM #140

Hi Bryan,

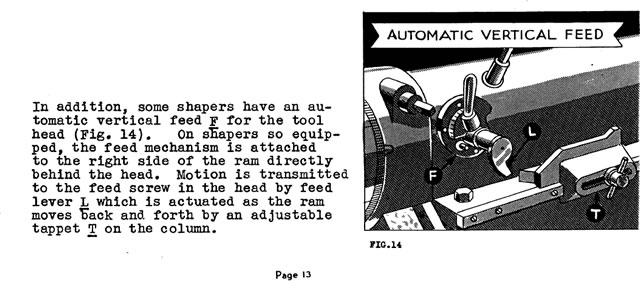

Here's another downfeed mechanism (not sure of the brand) it's from the Shaper book that is on Steve Lindsay's ( aka toolcat ) site that Dave Linked to.. Index of /shaper

I'm starting to think it's a doable upgrade..

Regards

Ray

-

16th December 2011, 11:56 PM #141Dave J Guest

Their is one around where a guy used a battery screw driver mounted to the feed screw, and a micro switch to activate it.

Dave

-

18th December 2011, 11:08 PM #142

Thanks for the idea Dave, I'm thinking I can do a simple automatic downfeed system with a stepper motor, proximity switch, and a bit of circuitry and software..

Getting the rust off and general cleanup is slow going, took most of today just to do the toolhead..

Brush and Kerosene (with special Sovereign Hill parts washing dish) for the sides..

Being left out in the weather, has meant that water has crept in and rusted all sorts of unexpected places.

This is inside the clutch lever housing..

When I get to the front of the machine, I'll be pulling the table off and checking behind it to see how much rust has gotten into the swivel mechanism.

Anyone got any good designs for tool holders? Is there anything I need to watch out for?

Regards

Ray

-

19th December 2011, 05:58 AM #143

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

-

19th December 2011, 09:04 PM #144

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 59

- Posts

- 2,557

I know that's your comfort zone Ray, so why not? I have a fondness for mechanical systems, but if I had your skills that bias might shift.

Starting to look great. You don't realise how dirty a machine is till you start cleaning it. Rewarding though. It really looks in exceptional nick.Brush and Kerosene (with special Sovereign Hill parts washing dish) for the sides..

Holders can be dead simple to get started. Here's the first one I made, and I still use it for almost everything. It's made from two pieces - one slotted, one tapped, then welded together and finished. Some people swear by spring holders. I haven't tried one but if I came across a big old one I'd grab it to try. The other approach is to clamp the tool directly in the post. Again I haven't tried it but I would want something bigger than 3/8 for this. 5/8 maybe.Anyone got any good designs for tool holders? Is there anything I need to watch out for?

-

19th December 2011, 09:52 PM #145

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Looks great Bryan. I really should make something like that one day. I've just been using a lathe tool holder, makes life a little harder as you have to allow for the rake angle built into the holer when grinding tools.

Is is the same size both ends?

Stuart

-

19th December 2011, 10:03 PM #146

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 59

- Posts

- 2,557

Stuart, yes I made it double-ended thinking I could rotate it to swap tools but I never use the other end. I find it easier to slip a different tool in the same slot.

-

19th December 2011, 10:21 PM #147

Thank Bryan,

Consider it copied.. What size HSS do you use, I'm thinking 1/2x1/2 for general work.

What size HSS do you use, I'm thinking 1/2x1/2 for general work.

Spring tool holder? is that the swan necked ones?

I read somewhere about having the tool cutting point behind the clapper box, and that supposedly would stop "digging in", but that seems wrong to me, wouldn't that stop the clapper box from pivoting and cause a dig in on the backstroke?

I've probably misread it..

Regards

Ray

-

19th December 2011, 10:43 PM #148

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 59

- Posts

- 2,557

I use 3/8 but 1/2 would be better.

Yep.Spring tool holder? is that the swan necked ones?

I think you've understood the issue perfectly. In theory the cutting edge is supposed to be directly in line with the back face of the clapper. In practice it's only an issue for slotting. I made an offset one but I don't think it made much if any difference. I find tool shape and feed rate more important.I read somewhere about having the tool cutting point behind the clapper box, and that supposedly would stop "digging in", but that seems wrong to me, wouldn't that stop the clapper box from pivoting and cause a dig in on the backstroke?

I've probably misread it..

Edit: Actually that's not right. In theory it should be in line with the centre of the pivot pin as that's the lowest point of the arc.

-

19th December 2011, 10:46 PM #149

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

-

19th December 2011, 11:00 PM #150

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Ray,

You might be interested in this. Its about planers but most of it applies.

Stuart

Similar Threads

-

shaper

By jonroe in forum METALWORK FORUMReplies: 3Last Post: 27th September 2011, 12:02 AM -

Shaper

By Anorak Bob in forum METALWORK FORUMReplies: 43Last Post: 19th March 2011, 10:18 PM -

TOS shaper

By Bryan in forum METALWORK FORUMReplies: 91Last Post: 16th March 2011, 05:58 PM -

Shaper vid

By .RC. in forum METALWORK FORUMReplies: 6Last Post: 1st October 2008, 11:03 PM