Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 42

Thread: Vise Bargain

-

1st November 2010, 01:24 PM #1

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 59

- Posts

- 2,557

Vise Bargain

Vise Bargain

63mm toolmakers vise back down to $55:

63MM-2.5"QUICK ACTION PRECISION TOOLMAKERS' VISE.

(No connection with the seller, just happy with mine.)

-

1st November 2010 01:24 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

1st November 2010, 03:37 PM #2Dave J Guest

I would be quick if you want one because they can change the price overnight.

The last time this was posted up I waited and it went up $5 but they were originally $70 so they could go back to that anytime.

The vice is good quality and has a really nice ground finish on it. Mine checked our square and parallel in all directions. It is a worth while accessory for the mill (big or small) or the lathe like Bryan has done.

Dave

-

5th November 2010, 12:57 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2008

- Location

- Canberra

- Posts

- 816

When I was milling some long stuff the other day I thought to myself it would be handy to have a matching vise to do this job (so I could clamp either end of the 600mm piece of steel I was working on).

Do you think I would be better off buying a matching vise (which I was going to do) OR, would I be better off buying two of the vises listed above? Cost would be the same.

Here is the vice I have and was going to get another one of.

5" (125MM) PRECISION SWIVEL MILLING MACHINE VISE (NEW) (eBay item 270652693517 end time 21-Nov-10 08:58:42 AEDST) : Industrial

Brendan

-

5th November 2010, 01:15 PM #4Dave J Guest

It will depend on what type of work you do. The larger vise will hold large things and be a lot stronger than the smaller ones in the link above. On the other hand if your only doing small stuff the little vises will do the job.

I bought one of those little ones to use in my larger vise for holding things at different angles and holding small delicate stuff.

Dave

Dave

-

5th November 2010, 01:17 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2008

- Location

- Canberra

- Posts

- 816

Cheers Dave. One of those little ones might come in handy on the lathe, should I ever get around to making a vertical slide for it, but given my mill is big and suited to big jobs I reckon ill get a matching 5 inch vise to enable this.

Thanks again,

Brendan

-

5th November 2010, 01:23 PM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

At 600mm you might be better clamping directly to the bed.

As far as two vices goes, I think you would be better of with a new matching vice.

2 x 125mm has to be better than 2 x 63mm doesn't it?

Stuart

-

5th November 2010, 01:29 PM #7

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2008

- Location

- Canberra

- Posts

- 816

Yeah clamping to bed would be ideal, but ill need to make a clamp set for it. The T slots on the bed are 25mm, and I cant find anything to suit.

Brendan

-

5th November 2010, 01:45 PM #8Dave J Guest

Hi Brendan,

That sounds like the way I would go. If you have a chance to get one of the little ones it will come in handy for some jobs on your mill.

I cant remember but do you have a surface grinder to give both the new one and your old one a skim over to make them the same height. The new one will be close but not exactly the same as you old one.

Another option could be to give them both a fly cut on your mill. I fly cut all the surfaces of my first vise that came with the HM52 as it was out all over.

With the swivel base I took a skim off the face plate in the lathe and bolted the base onto the face plate and took a face cut both sides.

Because it was such a large area I use the boring head to fly cut it.

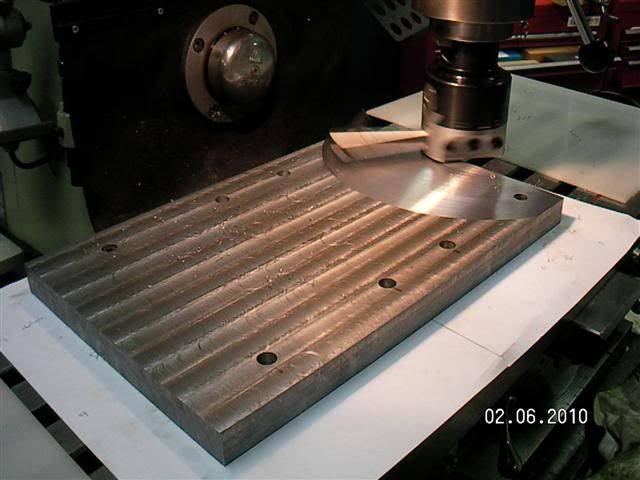

Here are a few pictures of doing a mild steel plate.

Dave

-

5th November 2010, 02:08 PM #9

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2008

- Location

- Canberra

- Posts

- 816

Man that is schmick. What DOC do you use when making a fly cut like that shown below? Do you get spring in the boring bar when you have it out that far?

How fast would you powerfeed?

-

5th November 2010, 02:22 PM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Pretty pictures Dave. I so want my granite block.

You don't add a link to some clever little table clamp thingies?

Disappointed!

luckily I found some

https://www.woodworkforums.com/f65/lo...45-mill-59191/

Tip 3--Horizontal mill table clamp

Aussie Hobby Metalwork: Vice Clamps

Stuart

-

5th November 2010, 02:46 PM #11Dave J Guest

Hi,

DOC is small, anywhere from 0.05mm to 0.15mm. The deeper the cut the more flex you will get, after getting it down to a uniform finish taking a 0.05mm finishing cut you get very little flex if any.

I plan to make up a large fly cutter but in the mean time this works fine. With a job like this it is best to clean it up with an end mill first, your cast iron wouldn't need it though.

As for feed all I can say is the slowest on the power feed, it takes a while. Not having coolant hooked up on this mill yet I found by halfway though the cut the HSS bit lost it's edge. I resharpened it and used a spray bottle of coolant and it lasted a few cuts, but my cloths were soaked at table height. LOL

That plate is 220mm x 340mm x 25mm thick mild steel and was for the head riser for my mill. I have since changed my plan and wont be using it in that spot anymore. Because I am going at it a different way, after finding out the horizontal spindle is out of square with the column.

Because I am going at it a different way, after finding out the horizontal spindle is out of square with the column.

Dave

-

5th November 2010, 02:57 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2008

- Location

- Canberra

- Posts

- 816

Thats really cool. Do you reckon you would have been better off with a carbide bit? How did you index your height once you resharpened the HSS?

Brendan

-

5th November 2010, 03:43 PM #13Dave J Guest

Hi Brendan,

I have carbide bars buy they left a poor finish, the HSS was superior.

With the height I put a wet tally ho cigarette paper on the job and when it takes that off I know I am real close. I then just wind the knee up a little until contact is made, move the cutter away and bring the knee up for the next cut X amount. From memory I got 3 cuts out of it after re sharpening and that was the job done.

Hi Stuart,

The plate is bolted to the table with socket head screws. I didn't want to drill them before fly cutting because of the interrupted cuts, but it made it easier for this job.

The last link is the same ones I recommended to Bryan, only with a pin at the front to go into the side of his vise.

The last link, I have never seen them made like that. I think if your going to make some like it, you would be better off doing them like these with the socket head screw head turned eccentric.

How to Flatten Bar Stock on a Mill? Not O/T! - The Home Shop Machinist & Machinist's Workshop BBS

Eccentric Clamps - Page 3 - The Home Shop Machinist & Machinist's Workshop BBS

There are other good right ups around on them, but they were the one's I could find quick.

Dave

-

5th November 2010, 05:01 PM #14

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

-

23rd November 2010, 09:08 PM #15

Senior Member

Senior Member

- Join Date

- Apr 2009

- Location

- Ballina N.S.W.

- Posts

- 371

vise bargin

vise bargin

eskimo,or other vise owners.

I am after one of these small toolmaker vises, how did yours come up after inspecting it?. I have just seen some similar ones a bit smaller 50mm across the jaws that came from Hong Kong but they were very rough with missing pieces of casting on the bed and movable jaw and would take half a day to remove all of the burrs from underneath. Any advise appreciated.

Bob

Similar Threads

-

Pen vise

By Simomatra in forum WOODTURNING - PEN TURNINGReplies: 9Last Post: 24th January 2008, 06:18 PM -

Tiger vise

By Tiger in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 3Last Post: 21st May 2007, 02:49 PM -

Vise Jaws

By legin in forum WOODWORK - GENERALReplies: 6Last Post: 22nd January 2006, 11:57 AM -

Z-vise with case 299.99

By jalamasurfer in forum HAND TOOLS - UNPOWEREDReplies: 6Last Post: 24th February 2005, 08:59 PM