Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 136 to 150 of 159

Thread: Wow - huge price difference

-

15th September 2012, 07:34 PM #136

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- ringwood vic

- Posts

- 251

G'Day Fellas,

Had a play with the the Fotek PL-05 proximity sensor, simple to hook up, a bit fiddly to mount and adjust the working distance ( 5mm) , but works fine although not as responsive as the Sick reflective, it took about a second to catch up on large swings in speed, but for the princely sum of $4.60 it could be worth considering.

Regards,

Martinf1.jpg

-

15th September 2012 07:34 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

15th September 2012, 07:44 PM #137

Sounds like another good option Martin. What are you aiming it at?

Rob, with the computer fan, are you pushing the air through the motor or pulling it?

I'm looking the flywheels that were in the treadmills and i think there is enough meat there to machine one pulley, and then mount another outboard over the multi v pulley. this way i can keep the original fan and add another.1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

15th September 2012, 09:16 PM #138

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2012

- Location

- SA

- Posts

- 1,478

Hi Ewan,

I'm pulling the air through the motor from the (cleanish) drive belt enclosure at the pulley end and exhausting into the drip tray area.

If you go the other way you will probably get metal cuttings sucked into the motor which on a DC permanent magnet job is bad news.

You're right about the flywheels being good candidates for machining pulley "V's" into. My setup is pretty tight on space so I've left that option as a last resort.

V pulleys are pretty easy to machine. I made some up for a reduction gearbox and it was no problem if you use a narrow (35 degree) cutter to profile them.

I've ordered one of these to play with re the tacho.

eBay Australia: Buy new & used fashion, electronics & home d

Be interesting to see how it goes.

Where did you get your gadget from Martin ?

Cheers all

Rob

-

16th September 2012, 12:06 AM #139

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- ringwood vic

- Posts

- 251

G'Day Fellas,

The sensor came from uxcell, it is aimed at a single slot sector disk mounted on the end of the spindle, If I was doing it again I would buy a tubular proximity sensor as I think it would be easier to mount and adjust. When they say working distance is 5mm they are not kidding, it is 5mm +/- a gnats nut, I still have to play with the Omron EE-Spy reflective sensor. I will probably stay with the Sick reflective sensor for the lathe, I'm playing with various sensors mainly to see what will be most suitable to fit a tacho to the RF31 and possibly the drill press (cant be stuffed opening covers to check belt positions).

Regards.

Martin

-

16th September 2012, 09:55 AM #140

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2012

- Location

- SA

- Posts

- 1,478

Is this the one your talking about Martin?

5-8mm Hall Effect Proximity Sensor Magnetic Switch DC 6-36V NPN NO 300mA | eBay

I looked at those and wondered if they would be fast enough?

Cheers

Rob

-

16th September 2012, 10:26 AM #141

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2012

- Location

- SA

- Posts

- 1,478

Ewan if you add PC fans and retain the original one as well, when you reverse the motor the fans will fight against each other.

PC case fans only rotate in one direction.

Also check to see how the pulley is mounted as some screw on, and when you reverse the motor they can screw off.

My 2 HP motor has a plain shaft with a flat, not sure what the 1.5 HP has as I've just tossed it in the corner for now.

Rob

-

16th September 2012, 05:50 PM #142

Hi Rob,

I'm sure i would have worked the fan thing out....eventually!

The pulley's are keyed and held on with a set screw, no worries about reversing. I'm really keen to get this up and running, the lathe only has a 3 amp peak, 1/2 hp on it at the moment and it's a bit gutless, plus the speeds it is set up with are a bit widely spaced and i have a habit of using only 2 speeds.....one for small stuff and one for large as the flat belt likes to slip on the smaller pulleys.1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

16th September 2012, 06:05 PM #143

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2012

- Location

- SA

- Posts

- 1,478

Hi Ewan,

What lathe do you have? Flat belt - must be a Hercus ? You might have belt slip problems with the extra HP. "V" belts next ?

BTW I spent the last couple of hours with that Hall switch mounted in the toolpost so I could finely adjust the position and various/many magnets mounted in/on my four jaw chuck and I tried everything to get that damn tacho to give a steady reading below 200 RPM.

No way. So that's it. Finito.

Good thing the pulley is keyed. Mine isn't. Some weird engineering in these treadmills. Some of it is really well thought out and heavy duty and other stuff is quite weak.

My 2 HP motor had a huge flat on the shaft and an absolutely puny little grub screw holding the original pulley. I made up a new cast iron pulley this arvo and it's got a good strong grub screw in it. A key would be better but there's no way this will move.

Cheers

Rob

-

16th September 2012, 06:24 PM #144

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- ringwood vic

- Posts

- 251

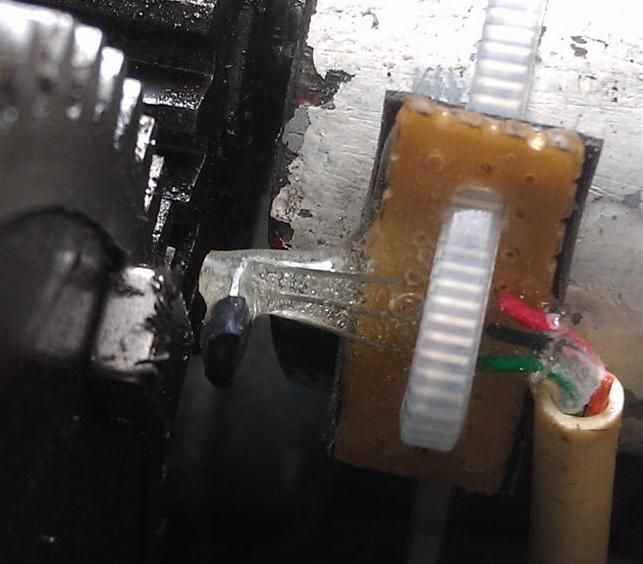

G'Day Blokes, (& Blokesses)t7.JPGt8.JPG

Setup the Omron EE-SPY reflective sensor and am most impressed, dead stable, almost instant response, no need for a sector plate, just a bit of black electrical tape on the spindle,(will add a stripe of black paint eventually). Hookup dead easy, it needed a pullup resistor, the case is from Jaycar, cut in half so you get 2 for the $18.00. Total cost tacho $12.00, sensor $9.25, case $9.00. not bad for $30.00 all up. Have fun playing with your versions.

Regards,

Martin

-

16th September 2012, 06:28 PM #145

-

16th September 2012, 06:42 PM #146

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- ringwood vic

- Posts

- 251

G'Day,

It was from uxcell, if you go to the Omron website and download the data sheet you will see the various EE-SPY types with different mountings and outputs, Omron recommend you use their plug and cable, but I got away with soldering to the pins (heatsink and work fast with a small iron).

Regards,

Martin

-

16th September 2012, 07:54 PM #147

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2007

- Location

- melbourne australia

- Posts

- 2,643

what value is the pull-up resistor?

-

16th September 2012, 08:02 PM #148

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- ringwood vic

- Posts

- 251

Hi Jack,

200 ohms was nearest to hand, works fine.

Regards,

Martin

-

17th September 2012, 02:56 AM #149

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2007

- Location

- melbourne australia

- Posts

- 2,643

Thanks Martin.

I'm going to give the HE sensors a miss. Sounds like they are too finicky. I'll order a EE-SPY optical sensor from uxcell and mount it in a similar place as you did.

-

18th September 2012, 08:11 PM #150

Hi all,

Got my HE sensor in position today, just cable tied at the moment until i am 100% happy but it is working fine. I will put the tacho in the same box as the DC controller but i have to wait till i have the controller to know what size box to get.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

Similar Threads

-

meter cube price to board size price - conversion tool

By old_picker in forum TIMBERReplies: 7Last Post: 27th January 2013, 09:21 PM -

What to do with a huge burl

By Microbe in forum WOODWORK - GENERALReplies: 51Last Post: 29th June 2008, 10:57 AM -

Huge Redgum log

By DJ’s Timber in forum SMALL TIMBER MILLINGReplies: 23Last Post: 3rd September 2007, 03:36 PM