Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 28 of 28

Thread: drilling

-

31st December 2011, 11:56 PM #16

Hey Pariss. Are you competing with Bam Bam for the neatest looking shed? I can't believe you have a shed that you can eat your dinner off the floor - best set up I have seen for a long while. Should only be another 3 weeks before I can get my new shed online. Its a Stratco 4.5 x 3.5 shed that I am going to line with spare bats from the house extension and seal it with light 3 ply. It will also be airconditioned with a spare mobile unit I have for the hot days and have a small timber room about 1x1 metre outside for the dust extractor outlet to protect it from the weather. Not the perfect shed but as we are leaving our house (and renting it) to move into my mother's house to look after her it is the best option I have. I will post some pictures of it and cooking breakfast on the floor of the shed

Happy New Year

Greg

-

31st December 2011 11:56 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

1st January 2012, 08:36 AM #17

Hey Greg, your shed sounds great !!. My shed is 4X9 metres. I have to put my work ute in there at night, so all the machines etc are strategically positioned. Also, I get a few local customers calling in to home to get locks re-keyed and keys cut etc, so I have to keep the shed as clean and tidy as I can. Have a great New Year mate.

Steve.

-

1st January 2012, 08:46 PM #18

Senior Member

Senior Member

- Join Date

- Mar 2011

- Location

- New Zealand

- Posts

- 186

Hi Greg,

It's no contest in the neatest shed competition. Pariss would win hands down. I had a clean up on the drill press before I took my photos, all the sawdust is now on the floor.

I have a 6x8 shed, that's to good bit. I have to share it with two cars, bikes, the garden tools and the washing when it rains. That does not leave much room for the machines, benches and a timber stash. Enjoy your new shed when it is up and running.

Happy New Year

Michael

-

19th January 2012, 10:58 PM #19

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Mar 2011

- Location

- brisbane

- Age

- 53

- Posts

- 579

Well after much thought, consideration, bribery (two pairs high heels) and some savings, went out and bought a CT drillpress, 82mm quill travel and a floor standing model. Hopefully dodgy holes are a thing of the past. Will post some pics when its out of its box.

Neal.

-

20th January 2012, 09:38 AM #20

As long as you lie about the price you paid for the tool the amount you have to pay in bribery can be a lot less

A ground standing model sounds impressive. My little Ozito on the workbench does the job as long as I put timber under the jib to raise it. My only problem is the 14.5mm drill won't fit into the chuck. I will get a tapered one when I find the time but at the moment I turn the 14.5 by hand hled by lockable pliers with the blank in a vice after I drill out with a 14mm bit. It works ok but it is a bit slow.

A ground standing model sounds impressive. My little Ozito on the workbench does the job as long as I put timber under the jib to raise it. My only problem is the 14.5mm drill won't fit into the chuck. I will get a tapered one when I find the time but at the moment I turn the 14.5 by hand hled by lockable pliers with the blank in a vice after I drill out with a 14mm bit. It works ok but it is a bit slow.

-

20th January 2012, 01:44 PM #21

Sounds like you have a 1/2" capacity drill chuck. The chuck end of a drill (the shank) is normally not hardened and can be turned to fit your chuck

without metal cutting gear you can even spin it in your wood lathe in your lathe chuck ,and file it down a bit to fit the drill chuck . Cheers John

without metal cutting gear you can even spin it in your wood lathe in your lathe chuck ,and file it down a bit to fit the drill chuck . Cheers John

Some decent auto electricians have a small bench lathe for some of the work they do,might find one to turn your drill for you, only a 5 minute job G'day all !Enjoy your stay !!!

G'day all !Enjoy your stay !!!

-

20th January 2012, 03:29 PM #22

Thanks for that information John.

There is an old style auto electrician just down the road from me. He will have the gear as he still keeps supplies for T Model Fords and any other car that has been made since his father or grandfather set the business up decades and decades ago. He is in the process of renovating a steam roller so he will have a lathe. I will get down and see him as soon as I move house this weekend.

Greg

-

20th January 2012, 04:59 PM #23

Senior Member

Senior Member

- Join Date

- Aug 2010

- Location

- Nowra NSW

- Age

- 51

- Posts

- 188

Mate I started a thead like this myself a while ago (about a year maybe less) as I had a bench drill press and was having all the same dramas that you are having. I bit the bullet and went and bought a free standing drill press I think from memory it was just over $300 but it has paid for itself a few times. I also use one of the blank drilling vices from timberbits.

I know it is a bit of money all up but it is worth the amount of frustration it fixes (especialy when you have a very short fuse like I do)

-

20th January 2012, 05:51 PM #24

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Mar 2011

- Location

- brisbane

- Age

- 53

- Posts

- 579

Done and done Jack, i could have gotten away with what i had, however for the cost of the press and the jigger it was not worth it to try and persevere, now i have to set em up and learn em, bring on the fun.

Neal.

-

20th January 2012, 06:57 PM #25

Hey Neal

Buy a ticket for the wife and kids to MovieWorld and get into the pens.

Greg

-

23rd January 2012, 12:55 PM #26

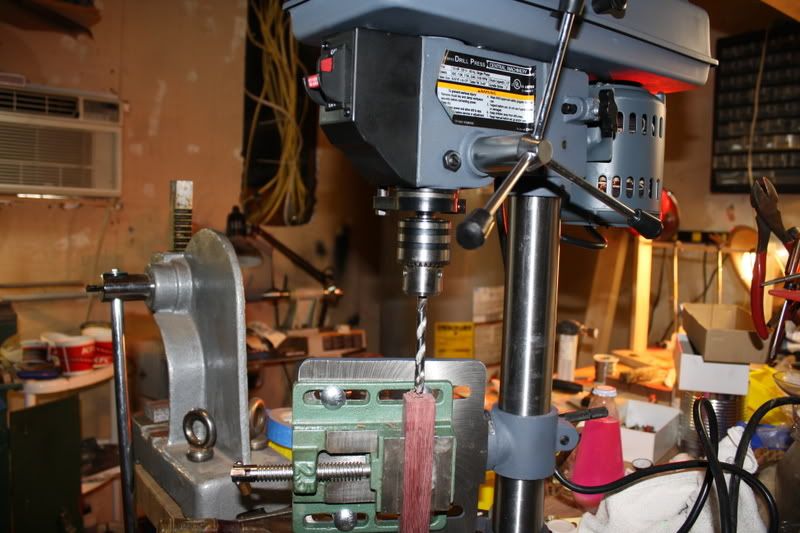

A table top el cheapo drill press from the "Made in China" tool store, about $79.00 American, came with the drill press vice.

Turn the table 90 degrees, the vice is held on with big wing nuts and bolts, which allows it to slide in and out towards the support tube.

You can dead center a blank quite quickly.

Drill the length of the quill feed, raise the bit back out, and simply loosen (open) the vice slightly, slide the blank farther up the bit, tighten the vice and drill through."That's why I love my computer,,,,,,,, my friends live in it."

- Colin Greg, Barnsley, South Yorkshire, England

Pen Turner Extraordinary and Accidental Philosopher.

-

23rd January 2012, 10:12 PM #27

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Mar 2011

- Location

- brisbane

- Age

- 53

- Posts

- 579

Cheers Ed, thats quite some lateral (forgive me) thinking you got going on there, i wouldn't have thought of that, but i'll definatly keep it in mind as another way to utilise the press now, cheers mate.

Neal.

-

24th January 2012, 08:24 AM #28

Thanks Neal,

I noticed in your original posting that you mentioned you had one of these “inexpensive” type drill presses…I have been using this one solely for this purpose for a few years.

Being a cheapskate, I figured it was the cheapest and easiest way to go.

You can drill the entire length of the drill bit this way with a little practice."That's why I love my computer,,,,,,,, my friends live in it."

- Colin Greg, Barnsley, South Yorkshire, England

Pen Turner Extraordinary and Accidental Philosopher.

Similar Threads

-

Drilling

By _Richard in forum WOODWORK - GENERALReplies: 3Last Post: 19th May 2010, 11:29 AM -

Pre-drilling

By funkychicken in forum METALWORK FORUMReplies: 12Last Post: 23rd November 2009, 10:54 AM -

Drilling jig help

By STEAM in forum METALWORK FORUMReplies: 19Last Post: 18th June 2009, 10:40 PM -

Drilling rig

By Steve Fryar in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 1Last Post: 28th February 2009, 11:36 PM -

cnc drilling

By echnidna in forum CNC MachinesReplies: 3Last Post: 21st February 2009, 02:35 PM

Reply With Quote

Reply With Quote