Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 8 of 8

Thread: Ouch!

-

23rd June 2007, 05:02 PM #1

Ouch!

Ouch!

I just burned the devil out of my fingers drilling a pen blank.

The bit (27/64ths) was too large for my drill press so I was drilling it on my lathe with a homemade apparatus. I got to the last quarter inch or so and decided to hold it by hand. I think I had the lathe speed to far up and maybe I hit the solid shaft of the bit or something cause all of a sudden that blank got very hot. I didn't let go though, it was too nice of a blank.

The bit (27/64ths) was too large for my drill press so I was drilling it on my lathe with a homemade apparatus. I got to the last quarter inch or so and decided to hold it by hand. I think I had the lathe speed to far up and maybe I hit the solid shaft of the bit or something cause all of a sudden that blank got very hot. I didn't let go though, it was too nice of a blank.  My index is blistered and my thumb and middle are a bit numb.

My index is blistered and my thumb and middle are a bit numb.

The good news is that there was no burning on the pen blank itself, it appears to have escaped without harm.

-

23rd June 2007 05:02 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd June 2007, 05:09 PM #2

Hello Matt, take care, use a leather glove if you must do it that way

,However very pleasing to hear the blank is ok!!!!

,However very pleasing to hear the blank is ok!!!! Amos

Amos

-

23rd June 2007, 05:34 PM #3

Matt, I really don't recommend getting your blanks that hot. And not just 'cos it burns your fingers.

Even though you mightn't see visible signs of charring or burning, the odds are that you've overheated the wood and caused what I call "micro-fractures" around the bore. Some woods are more prone to this than others, acrylics are highly susceptible.

Considering that with a pen you turn most of it away except for the piece around the hole, well... if I were you I'd make sure you do a good job of gluing the tube in, 'cos otherwise you've doubled (or worse) the chances of the blank shattering when nearly finished.

Hope it turns fine for you though, and don't forget to post pix!

- Andy Mc

-

23rd June 2007, 06:12 PM #4

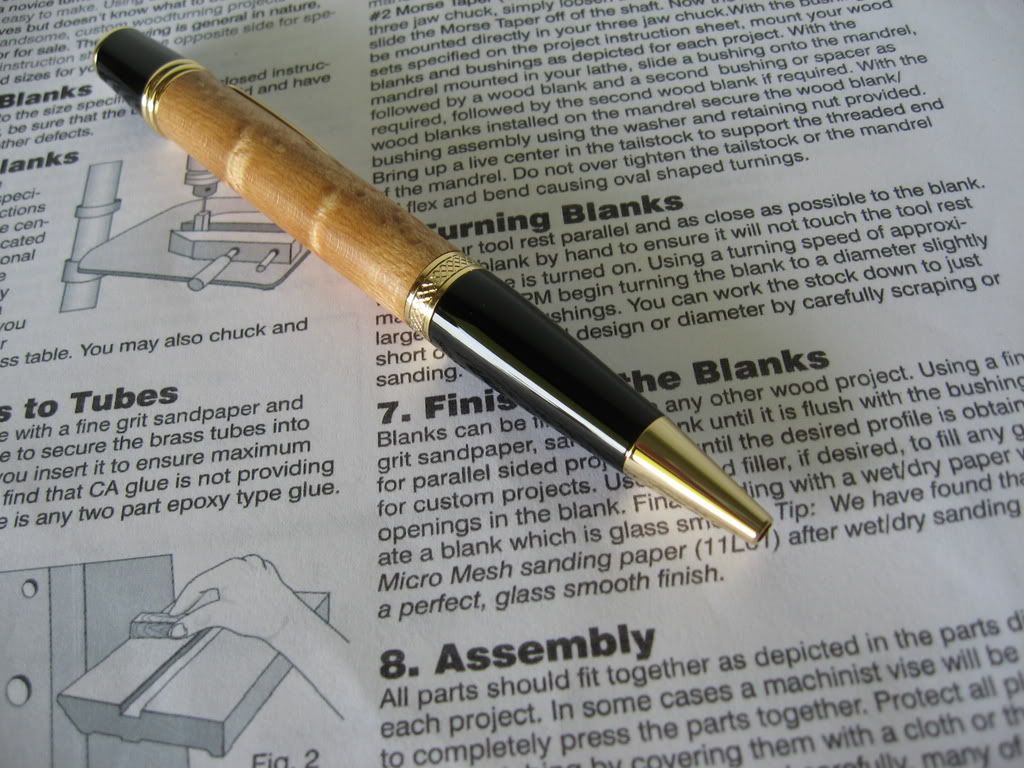

I try to be careful and not overheat them but this one got away from me, I don't usually drill them on the lathe. It was alright until that last bit, must have been all the friction from having the bit almost all the way through. This was a piece of maple, hopefully it takes heat better than some of the harder denser woods do. I was extra careful to to rough up the inside of the blank and I put extra deep scratching on the tube, hopefully it holds, its a nice piece of birdseye maple. Naturally if everything goes well I'll post pics, its going on a gold Wall Street II.

Cheers!

-

23rd June 2007, 11:22 PM #5

As Skew said Matt even with normal drilling conditions the heat can cause 'micro-fractures'. For this reason I always line the inside of my timber blanks with thin CA whether I think it is needed or not. The thin CA will wick into any of the fine cracks and it gives a good gluing surface for the roughed up tube to adhere to.

Darren

-

24th June 2007, 02:37 AM #6

I'd use the lowest speed available for that size, especially in end grain. Also, withdraw the bit completely and often for cleanout; you may have been burnishing the inside of the hole with the cuttings - that gets hot in a hurry. My rule of thumb: If it's too hot for me, it's too hot for the wood.

JoeOf course truth is stranger than fiction.

Fiction has to make sense. - Mark Twain

-

24th June 2007, 02:18 PM #7

Well all done. No pics yet though, I'll try to get those up later either tonight or in the morn.

I'd never turned a Wall Street II before, dang that wood gets thin. It went well except for one catch that I though did me in but I was lucky to have just enough wood left to work it out. It doesn't look as good as I had hoped it would. It's a piece from the same birdseye maple bit I made those Atlases out of before but it doesn't seem to look the same. Maybe I need to drag out the Atlases and compare. It just seems like its a bit darker and the birdeyes don't seem to have as much luster. Meh.

It went well except for one catch that I though did me in but I was lucky to have just enough wood left to work it out. It doesn't look as good as I had hoped it would. It's a piece from the same birdseye maple bit I made those Atlases out of before but it doesn't seem to look the same. Maybe I need to drag out the Atlases and compare. It just seems like its a bit darker and the birdeyes don't seem to have as much luster. Meh.  These things happen. Could be the wood, could have been the heat I suppose. It looks all right though. I was hoping for spectacular though.

These things happen. Could be the wood, could have been the heat I suppose. It looks all right though. I was hoping for spectacular though.  It's for my bosses birthday, I've known her for well over the last decade and worked with her for half that. I will be leaving soon to start another career, so I was hoping for a special B-day gift.

It's for my bosses birthday, I've known her for well over the last decade and worked with her for half that. I will be leaving soon to start another career, so I was hoping for a special B-day gift.

Anyone ever do Wall Street II's? I saw a couple on here and they looked nice so I though I'd give them a try. I like they way they write, they seem to write better than some kits. They seem to go together kind of funny though. All my ends matched up perfect before I assembled then after I assembled my front seam is a bit off, you can barely tell but I think its because the front isn't pressed into anything, just the back, and the clip presses so hard on the side. Just my theory though.

I'll get some pics up so you can see what I'm talking about though.

-

25th June 2007, 02:43 AM #8

Similar Threads

-

Ouch.

By soundman in forum WOODWORK - GENERALReplies: 26Last Post: 18th May 2007, 09:45 PM -

Ouch

By thefixer in forum WOODTURNING - GENERALReplies: 22Last Post: 17th May 2007, 01:25 PM -

A Small Ouch

By rod1949 in forum HAVE YOUR SAYReplies: 6Last Post: 7th December 2005, 07:30 PM -

Social experiment

By Driver in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 19Last Post: 7th December 2005, 12:15 PM -

Ouch.

By zenwood in forum NON WOODWORKReplies: 22Last Post: 28th October 2005, 11:18 PM

Reply With Quote

Reply With Quote