Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 24

Thread: Pen Press ideas needed

-

26th January 2009, 11:45 AM #1

Jen

Jen

- Join Date

- Jul 2008

- Location

- Kirwan

- Age

- 64

- Posts

- 107

Pen Press ideas needed

Pen Press ideas needed

Hi everyone, I have surfaced from the past and ready to get back into pens after having a play with bowls for awhile.

Major problem Im having is assembling my pens. To date I have used a wooden mallet and gentle touch, but when I tried that with a baron...... oooooo what a disaster. So , I am now asking all you experts out there the best way to assemble pens and a good way to make a pen press or where to get one.

All ideas greatly welcome

and Happy New Year to you all as well

Jenny

Life's short.... enjoy it!!

Life's short.... enjoy it!!

-

26th January 2009 11:45 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

26th January 2009, 11:53 AM #2

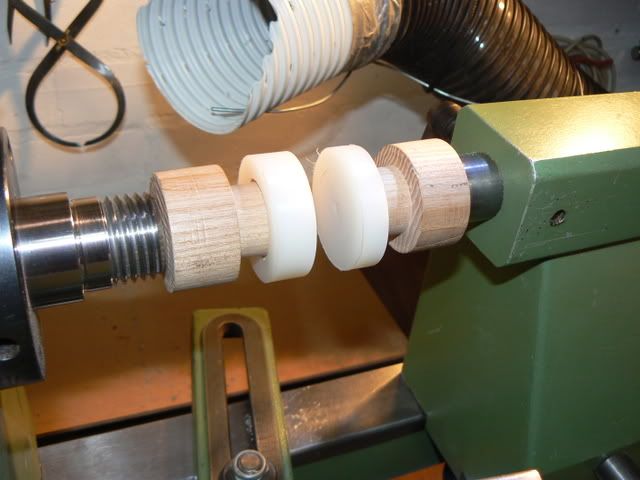

This is what I use.

Haven't had a failure yet (touch wood )

)

-

26th January 2009, 11:57 AM #3

Pen Assembly Press

Pen Assembly Press

This is our option

http://www.cws.au.com/cgi/index.cgi/..._id=1107458878Jim Carroll

One Good Turn Deserves Another. CWS, Vicmarc, Robert Sorby, Woodcut, Tormek, Woodfast

Are you a registered member? Why not? click here to register. It's free and only takes 37 seconds!

-

26th January 2009, 02:36 PM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2008

- Location

- Maryvale, Queensland

- Posts

- 2,338

Mine is similar to Fred's, but I just use my normal drill press. A piece of cutting board on the table, and one of those rotary sanding wheels that go in the drill - it has a nice smooth hard plastic centre that everything is glued to, which is what I use to press the pen bits together. Didn't cost me a cent as I already had the bits.

Russell.Pen Affair Craft Supplies - Cheapest Pearl Ex & Pemo Polymer Clay in Australia

http://craftsupplies.penaffair.com

-

26th January 2009, 02:54 PM #5

I use an arbor press...cost me $24.00 American at the "made in China" tool store.

You can't break it if you tried, and it allows you to apply pressure in a very controled manner...plus, with a little rigging up, it make a great dissassembly too also.

This is a 1/2 ton press, just the right size for pens.

-

26th January 2009, 03:16 PM #6

Haven't seen the 1/2 ton one, but a 1 ton one costs $A130, just a little more!

-

26th January 2009, 05:20 PM #7

Hi Jenny

I use a triton super jaws

Andrew

-

26th January 2009, 05:50 PM #8

A drill press is a good way to go,you can mount a piece of dowell in the chuck to protect parts, and as you have a vertical alignment its fairly easy to keep everything in line while applying pressure. Better than a hammer any day hehe.

-

26th January 2009, 07:41 PM #9

Hi Jenny,

Its quick, accurate, cheap and you can feel just how much pressure is required at every stage. Also simple to make.

beejay

-

26th January 2009, 08:36 PM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2006

- Location

- melbourne

- Age

- 63

- Posts

- 587

G`day I use a large quick grip clamp and a woodworking vice.

Mick

-

26th January 2009, 08:51 PM #11

-

26th January 2009, 10:21 PM #12

I've been using this high tech solution for more than two years without a single problem.

When all is said and done, there is usually a whole lot more said than done.

-

27th January 2009, 07:57 AM #13

I use the quick grip clamp too (it's the small one - about 200mm) - I got a pack of 4 of them for about $25 at bunnies a while back.

I keep thinking I should do something more sophisticated, but as I've never had any grief with it, I haven't ever bothered...

Cheers,

Dave...but together with the coffee civility flowed back into him

Patrick O'Brian, Treason's Harbour

-

28th January 2009, 08:59 AM #14

I knew I shouldn't have posted my response.

"I've never had any grief with it" turned into " " last night when assembling a slimline in figured blackwood. I think I didn't glue the tube well enough at one end, but the rubber on the quick-grip clamp rounded off the wood a bit (kinda split it out a bit - I should have taken a photo). I'm tempted to use the pen mill to clean it up a bit but I'm not sure if I'm game.

" last night when assembling a slimline in figured blackwood. I think I didn't glue the tube well enough at one end, but the rubber on the quick-grip clamp rounded off the wood a bit (kinda split it out a bit - I should have taken a photo). I'm tempted to use the pen mill to clean it up a bit but I'm not sure if I'm game.

I like Beejay's idea - it looks pretty controllable, though I have the drill press stand bought from Aldi that Big Shed uses. I Currently use it for holding the heat gun while roasting coffee in a bread maker. I think it might have to start sharing duties between pens and coffee...

cheers,

DaveLast edited by Ozkaban; 28th January 2009 at 09:03 AM. Reason: speeling

...but together with the coffee civility flowed back into him

Patrick O'Brian, Treason's Harbour

-

28th January 2009, 09:05 AM #15

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2008

- Location

- Maryvale, Queensland

- Posts

- 2,338

Umm, LOL? I Think

I was in a rush ocne and didn't want to swap the drill but out of the press, so tried doing it by hand between two pieces of wood. I also rounded over the end of the pen when it slipped sideways. That was the last time I tried to do it not in the press.

Russell.Pen Affair Craft Supplies - Cheapest Pearl Ex & Pemo Polymer Clay in Australia

http://craftsupplies.penaffair.com

Similar Threads

-

Some shape ideas needed

By Joash in forum WOODTURNING - GENERALReplies: 7Last Post: 27th October 2006, 07:23 PM -

Ideas needed for display stand.

By Skew ChiDAMN!! in forum WOODWORK - GENERALReplies: 10Last Post: 14th January 2006, 08:30 AM -

How do I? Ideas and thoughts needed... PLEASE!

By Wild Dingo in forum WOODWORK - GENERALReplies: 6Last Post: 8th November 2005, 06:06 PM -

Ideas needed for bathroom cabinet

By zenwood in forum BOAT BUILDING / REPAIRINGReplies: 11Last Post: 21st July 2005, 10:38 AM

Reply With Quote

Reply With Quote