Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 32

Thread: Tulipwood Score!

-

23rd May 2008, 03:24 PM #1

Tulipwood Score!

Tulipwood Score!

I made a nice tulipwood score tonight. I've been eying some of the larger pieces at Woodcraft for sometime, bowl blanks were what they were, but they were large enough to get a cross cut pen blank out of, which I think (haven't tried yet though) would make a stunning pen. With the flow you just really don't get the full impact of tulipwood, I think cross cut will just pop out though.

Anyhow, although I'd been eying them, I hadn't wanted to outlay the cash they were wanting for them, they want some serious cash for some of their bowl blanks. They have one that is lignum vitae, probably 10x10x5", and they want like $80-90. It's lignum and a huge chunk of it but dang.

They have one that is lignum vitae, probably 10x10x5", and they want like $80-90. It's lignum and a huge chunk of it but dang.

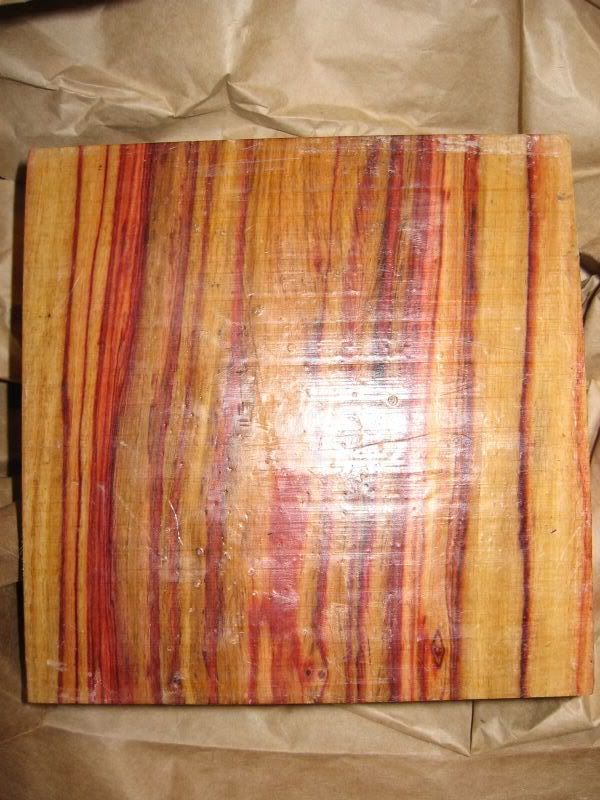

Anyhow, I had some time to kill tonight, and I was up by the woodcraft store so I stopped in to look around. Guess what I found in the clearance section? Tulipwood bowl blanks. They hadn't been moving so they gave up and chucked them in clearance. Look at what I got for $15.

They hadn't been moving so they gave up and chucked them in clearance. Look at what I got for $15.

I might go back and get another one or two. Problem is I'm sure this wood is green as all get out, and it will probably be a considerable amount of time before its ready to use.

It is however, just wide enough to get a baron blank out of it cross cut. Should be able to get a lot of blanks out of them due to their handy sizing.

Should be able to get a lot of blanks out of them due to their handy sizing.

Q. How much does a decent moisture meter cost?Wood. Such a wonderful substance.

-

23rd May 2008 03:24 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

23rd May 2008, 05:08 PM #2

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Wow!!!

Wow!!!

Congratulations Matt! Great score.

In Honor of this, my 1700th post you may send its twin to me!

-

23rd May 2008, 05:34 PM #3

Great find Matt don't forget to cut a few on the bias or cross cut

-

23rd May 2008, 08:09 PM #4

Matt

Matt

For drying I have been enjoying success having cut the blanks stickering them in piles. I weigh them at first and each week recording from each stack. This takes place in my roof space,it does not take long to equalise in weight. This is timely since you are coming into warmer weather I hope by now.

Timber looks great will soften in colour as it dries.

Regards Peter

-

23rd May 2008, 08:22 PM #5

Nice score, as Peter said... pen blank sizes wont take long to dry out. Wait until they reach a steady constant weight for a few weeks in a row and you are good to go

.

.

CorbsIt's only a mistake if you don't learn from it.

-

25th May 2008, 10:49 AM #6

I cut a piece off of the end, I think I can get 6 slices with 6 half blanks per slice for a total of 36 half blanks = 18 total pens, minus all the mess ups.

It's some beautiful wood, and I think I just figured out why it's called tulipwood. I always figured it was because of the coloring, but it's not is it? It's because it smells of tulips, lovely smell, probably the best smelling wood I've smelled so far.

I always figured it was because of the coloring, but it's not is it? It's because it smells of tulips, lovely smell, probably the best smelling wood I've smelled so far.

I just realized too that this is an incredible chance to get some mind blowing matching sets, possibly even 3-4 piece matching sets, and if I really plan it out, I might be able to squeeze a 7 peice set out, which would go along with something I've been plotting lately.

Any pipe smokers on here? If so, you're probably familiar with the "7 day sets" they have, which is basically a fancy set of pipes (sometimes matched in some way) with one for each day of the week. They also make 10 day sets and 12 day sets, etc, etc, I think dunhill made a 365 day set, cheeky buggers.

Anyhow, I was thinking of doing something along the same lines, say a 7 day set of pens, possibly of different models, say an emperor for Sunday, a Lotus for Saturday, Barons for the weekdays, something like that, but all with matching grain cut from the same peice.

Anyhow, just something I've been tossing around. Wood. Such a wonderful substance.

Wood. Such a wonderful substance.

-

25th May 2008, 12:07 PM #7

Matt

Matt

Heard of tiptoeing through the Tulips but you as a wood predator went several times better,good luck with the drying. It the timber is fantastic.

A mate of mine when I worked with CSIRO (Commonwealth Scientific Industrial Research Organisation) in the Forestry area bought a whole tree,felled,milled dried and shipped from Qld to Canberra by rail in cut order for less than Radiatar Pine (contacts) His home extension floor was laid with the timber.Georgeous result.

As you progress day by day plan show us the results.

Regards Peter

-

25th May 2008, 01:01 PM #8

Definitely some nice colour and grain the pens should look fantastic

-

25th May 2008, 03:54 PM #9

-

26th May 2008, 09:51 PM #10

Matt, absolutely beautiful, remember, as you get close to the finish, and even in the sanding stages, it would be wise to stabilise the xcut with CA, or it will blow out, had that happen with two lovely xcut tulip wood pens. Good luck, Amos

Good, better, best, never let it rest;

Good, better, best, never let it rest;

Til your good is better, and your

better, best.

-

26th May 2008, 10:14 PM #11

Mate hurry up hurry up is it dry yet

That is really nice timber should look awesome

That is really nice timber should look awesome

-

27th May 2008, 04:23 AM #12

Say now, that's some determination Peter, I think I'd like that chap.

Thanks for the advice Woodenink, I'll defiantly be forging ahead with care until I get the feel for this timber.

When I cut that slice up the other day I noted the sawdust and timber seemed to be fairly dry, perhaps I'm wrong, but I was going to give just one a try, I have a friend who just graduated, I was going to make a pen for a gift, I was thinking this would do lovely.

I should be able to tell further from the shavings coming off the lathe how dry or wet it is. If worst comes to worst I'll just have to seal the rough turned blank off and leave it to sit for a few weeks.

The blanks might be fairly dry. That hasn't been my experience with Woodcraft wood, usually it's straight from the rainforest. The blanks had however, been sitting on their shelf for probably the last 6 months, so they have had at least that time to season plus whatever they had before they arrived at the store.

The blanks had however, been sitting on their shelf for probably the last 6 months, so they have had at least that time to season plus whatever they had before they arrived at the store.

I'm going to give one a try, it's so humid around here it's not like its going to dry out quickly anyhow, and leaving anything unsealed might have the opposite effect, if it's fairly dry it might suck up moisture, but anyhow, I'll turn it and finish it in one session for sure.

I wish I had a larger pen to put it on, but I wanted to make a fountain pen and all I have and can get locally is the classic design/style, which is not a very large pen, should fit her hand nicely however.

It's going to be fun drilling it, I only have about an 1/8th of an inch on either end to work with, I'm going to glue a waste block on either end to (in theory) keep it from wallering the entrance hole or blow out the end.

Anyhow, wish me luck lads!

Wood. Such a wonderful substance.

Wood. Such a wonderful substance.

-

27th May 2008, 10:04 AM #13

Lots of luck.

I've got a bowl blank from Woodcraft in tulipwood, too. and you're right ..

their stuff is nowhere near ready to use. Finding that out cost me dearly in amboyna, jarrah, eucalyptus, myrtle burl etc. etc.

I know what you mean about a large pen .. tulipwood is hard to show off on something as small as a pen. But I'm cutting mine into larger pieces and using them for the perfume atomizers, They're wider and I tend to do them in a mushroom shape anyway, since it gives you more room to show off the grain patterns.

Looking forward to a few of these in tulipwood, but here's a couple of recent ones in case you haven't seen those kits.

-

27th May 2008, 11:44 AM #14

Ahhh, the Myrtle burl got you too? The pink stuff from down under they were selling by the pound? Yup, pink myrtle and cocobolo bit the snot out of me when I first started turning, I made several gearshift knobs for several of my cars, went through block after block and they would always develop hairline cracks after a few days, even after being coated knee deep in poly. When I finally figured out it wasn't something I was doing I went back in to Woodcraft and well, me and the manager still aren't on very good terms, we're pretty wary of each other.

Course first thing they did was try to sell me a jug of Pentacryl or whatever that stuff is they have in there that will displace the water, you just have to soak it in it for a couple days and you're ready to turn. It's about $20 a quart though and to have to pay that on top of their prices for green wood just adds injury to insult, besides I'm not big on chemical driers. They have their system pretty well worked out for milking everything out of their customers they can it seems.

Course first thing they did was try to sell me a jug of Pentacryl or whatever that stuff is they have in there that will displace the water, you just have to soak it in it for a couple days and you're ready to turn. It's about $20 a quart though and to have to pay that on top of their prices for green wood just adds injury to insult, besides I'm not big on chemical driers. They have their system pretty well worked out for milking everything out of their customers they can it seems.

What bugs me the most isn't that they (IMO) are ripping off their customers, but rather that much of that incredible wood is going to be ruined. They should at least give people a heads up so that the wood isn't wasted by people who don't know that it's green. That would probably cut their sales quite a bit though.

They should at least give people a heads up so that the wood isn't wasted by people who don't know that it's green. That would probably cut their sales quite a bit though.

I like the flow on the last one, it looks like a right proper mushroom. I would have never thought in a million years to shape them like you have, if I'd did them they would look like this. -> I

lol, I guess I'm to chicken to play with shapes much. Have you thought though, about turning that design upside down? So instead of a mushroom you have a "flower"? A little more shaping would be needed too, a little more dished in perhaps to make it look more flower like. Or you could get really wild and really turn it thin and then work on it after you've stopped with carving knifes to make the individual petals.

Just a thought.

Cheers!

MatthewWood. Such a wonderful substance.

-

28th May 2008, 01:07 AM #15

Well nope, not quite ready.

It was quite the fiasco altogether though. Some nights you should just quit while you're ahead.

It was quite the fiasco altogether though. Some nights you should just quit while you're ahead.

I glued waste blocks on the ends to keep them from blowing out, that went well, the ends were perfect. I went to insert the tubes however and the holes were very tight. I ran the bit through them a few more times, used a rat tail file on them a bit, still too tight for my taste. So I though, well, since its such a tight fit, maybe I should use super glue to glue them in there.

I never use super glue to glue in the tubes, actually I've never used it even once to do so, always use epoxy, however in this case with it being a tight fit, I thought the thinner CA would flow in there better and not just get squeezed out.

So I gave the inside of the blank and the outside of the tube a generous application of CA and slid the tube in. I got all but about an 1/8th or so in before it had set, the tight fit was accelerating the glue I think. So I panicked, grabbed the blank and smacked it on the floor to try to get the tube the rest of the way in.

All that accomplished was to glue the blank to my hand, all the CA I'd so liberally coated the inside of the blank and tube with had flowed outside the blank, I had it glued to my fingers and palm on three sides of the blank.

I managed to peel my hand free from the blank without loosing any skin, and went to do the next one. That one went better, quick application, slammed it home quickly with a piece of wood. Got more glue on me though, about 20% of my hand was now covered in CA.

So I trimmed the ends, just removed the excess on the one that hadn't quite went all the way in, I figured I'd adjust for it where I could and see if I couldn't get it to work, and went to turning.

It was kind of a little catchy to turn, but the shavings coming off seemed dry and would crumble between your fingers so I forged ahead. I had to use CA on the last few runs to get it smooth, the sides of the timber wanted to rough.

During sanding it cracked.

I was a little rough on it turning turning and sanding, it was late, I had CA all over me, it was being catchy, I should have went softer with it. Also the hole was probably too tight, that might have cause it to crack as well if it was pushing out in a place or two, the heat from sanding might have been too much.

However, I think I'm going to cut the rest of the wood into blanks and let it dry for another couple months, just to be sure. Keep them in the house where humidity is lower.

Meh. Wood. Such a wonderful substance.

Wood. Such a wonderful substance.

Similar Threads

-

Tulipwood Wall Street II

By Matt88s in forum WOODTURNING - PEN TURNINGReplies: 10Last Post: 30th September 2007, 09:28 AM -

Score

By wheelinround in forum HAND TOOLS - UNPOWEREDReplies: 5Last Post: 1st September 2007, 11:11 PM -

Tulipwood from Brazil

By PenTurner in forum WOODTURNING - PEN TURNINGReplies: 7Last Post: 14th June 2007, 04:11 PM -

purpleheart,tulipwood & padauk

By My Name is Burl in forum WOODTURNING - PEN TURNINGReplies: 9Last Post: 20th March 2007, 11:59 PM -

American Gift-Box Purpleheart and tulipwood

By zenwood in forum WOODWORK PICSReplies: 14Last Post: 29th August 2005, 06:49 PM

Reply With Quote

Reply With Quote