Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 17

Thread: Eave lining

-

5th February 2007, 08:40 PM #1

Eave lining

Eave lining

Hi All

I was looking at the original part of my house today (because I copy) and I noticed it appears that the lining between the tiles and the rafters ... what you see when you look up under the eves ... appears to actually be layed on top of the rafters. I had though until now that it was actually on battens between the rafters.

So am I actually correct? Is it possible / correct to put down a lining on top of the rafters out over the eve section ... then the tilers put their battens and tiles on top of that?

Further ... on a 1920 house what would the toungue and grove lining timber be ... is it available or should I use cement sheet (i'd prefer that but not sure it would look as nice)?

Thanks.

-

5th February 2007 08:40 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

5th February 2007, 08:52 PM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2005

- Location

- Victoria

- Posts

- 664

Yes, eaves are sometimes done like that,in much the same way as ceiling lining can be done on top of the rafters where the rafters are exposed.

Tools

-

5th February 2007, 09:15 PM #3

Thanks ... do you know what materials are common? I guess you could use cement sheet. But the rest of the house is soem sort of t&g ... I wouldn't expect pine would be weatherable enough ... maybe cedar? But what is commonly available these days?

-

5th February 2007, 09:40 PM #4

New Member

New Member

- Join Date

- Dec 2006

- Location

- Sydney

- Posts

- 9

Pine would most probaly be ok as its up and under the eave and wouldnt really get wet. Most probaly would be the chepest. Can also get in a plywood form which is used for exterior panneling.

-

6th February 2007, 01:01 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

Yes, it's very common to use T&G V groove pine for eaves linings. The tilers have to rebate their battens over it, then install a fibro strip on top of barge boards to cement the edges of their tiles down to. It's important to protect the pine from the weather until it's covered by sarking and tiles though. Water damage is bad, and so is what happens to it when exposed to too much sunlight. They can warp and distort quite easily when exposed, mkay.

It also helps to prime the backs to seal them and prevent them from cupping by having only one surface sealed, but that's not always done.

-

7th February 2007, 07:40 PM #6

Senior Member

Senior Member

- Join Date

- Dec 2004

- Location

- Coburg, Victoria

- Posts

- 383

and they are laid v-groove side up so that they look the same as the part you're copying

"World's oldest kid"

-

8th February 2007, 08:28 AM #7

Yep .. thanks ... got that bit.

One other thing I need to do is put on a tilt batten at the end of the rafters. I don't eactly understand the point of it ... could someone give me an explanation?

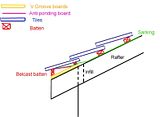

Attached is a diagram ... it is a 90 x 45mm ripped on the diagonal and I believe the ripped side goes down against the rafter ... is that the correct orientation?

Thanks!

-

8th February 2007, 09:15 AM #8

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

A tilt batten is called a 'belcast batten' and it's purpose is to give the last tile the same fall as all the rest. You see the last tile doesn't sit on a lower tile so it needs to be supported at a higher point on the plane.

I've made an illustration that explains how it should be done. You'll see an anti ponding board used to give the sarking proper fall into the gutter. The anti ponding board is usually Hardiflex.

You'll see that the batten on top of the V groove boards has to be thinner than the rest.

If there is a fascia board attached, then the belcast batten is nailed on top of it.

You can put the V groove boards either way up. One side has a V groove in the middle which gives the appearance of a narrower board.

-

8th February 2007, 09:54 AM #9

Thanks pawnhead ... helpful as always.

I was trying to work out why they were concerned about this batten going on before the guttering ... but I can see from you diagram that if it wasn't there the gutters would end up a bit lower so the water off the tiles may overshoot the gutters in heavy falls.

-

8th February 2007, 11:00 AM #10

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

My mistake, it's spelled with a double L.

Bellcast batten

edit: - Exactly. That's why the usual course of events is that the roof carpenter installs the bellcast batten and anti ponding board (not often installed, for cost cutting), then the roof plumber installs the gutter from the top of the bellcast, then the tiler installs the sarking, the rest of the battens, and tiles into the gutter.

-

11th February 2007, 05:59 PM #11

Hi Pawnhead ... I have painted both sides of the boards and put them up. They are big eaves so there are 6 long rows and the joins have been staggered and they are well nailed to the rafters. I have les than 2 weeks until the roof is on (I hope) so would I need to protect them any further?

I was going to cover in black plastic but I didn't have enough and its been so windy here today it probably wouldn't last the nigth anyway! What'd you think?

-

11th February 2007, 06:19 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Aug 2005

- Location

- Victoria

- Posts

- 664

I'd cover them if I was you...you don't want them to expand and twist.

Tools

-

11th February 2007, 06:57 PM #13

Yeah ... I'm sure your right ... just wasn't sure because the plastic gets so hot in the sun, would it help? Or does it help retain the moisture?

-

12th February 2007, 12:13 AM #14

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2005

- Location

- Sydney

- Age

- 63

- Posts

- 1,619

Well the paint would certainly help, but like Tools says it's probably better to be safe than sorry. I've had them twist up before and we had to replace a few of them, but they weren't painted on the back or anything.

A bit of that thin black plastic would be cheaper than having to replace them that's for sure.

-

12th February 2007, 07:17 AM #15

Thanks ... I'm in Melbourne too so it will probably reach 40 degree and snow before the roofs on!!

Similar Threads

-

Pine Lining Boards - Painting?

By geoffm in forum FINISHINGReplies: 4Last Post: 7th June 2009, 04:53 PM -

Lifes Storm Clouds Silver Lining

By dazzler in forum Hatches, Matches & Dispatches. Birthday greetings and other Touchie-feelie stuff.Replies: 35Last Post: 25th January 2007, 09:08 AM -

Fake suede for Box lining

By Barry F in forum WOODWORK - GENERALReplies: 13Last Post: 2nd July 2005, 10:25 PM -

Basement workshop lining and fitout

By numbat in forum WOODWORK - GENERALReplies: 23Last Post: 20th March 2005, 01:49 PM -

finishing plywood lining.

By Pulpo in forum FINISHINGReplies: 6Last Post: 16th March 2005, 05:35 PM