Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 22 of 22

Thread: trying to solder copper pipe

-

12th December 2007, 09:57 AM #16

Novice

Novice

- Join Date

- Nov 2007

- Location

- Adelaide

- Posts

- 17

ok piccies to find out what is going wrong...or wether i am heading in the right direction.

first my attempt at the soft solder:

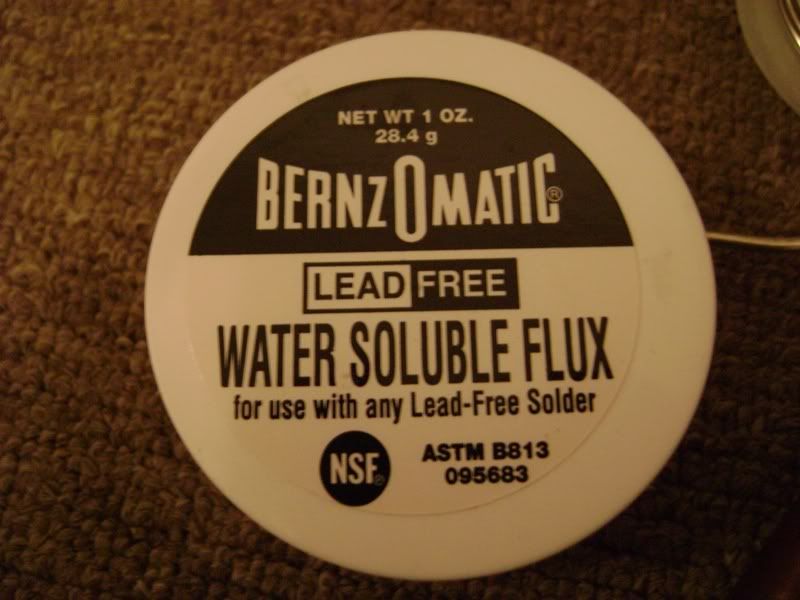

this is the flux i used

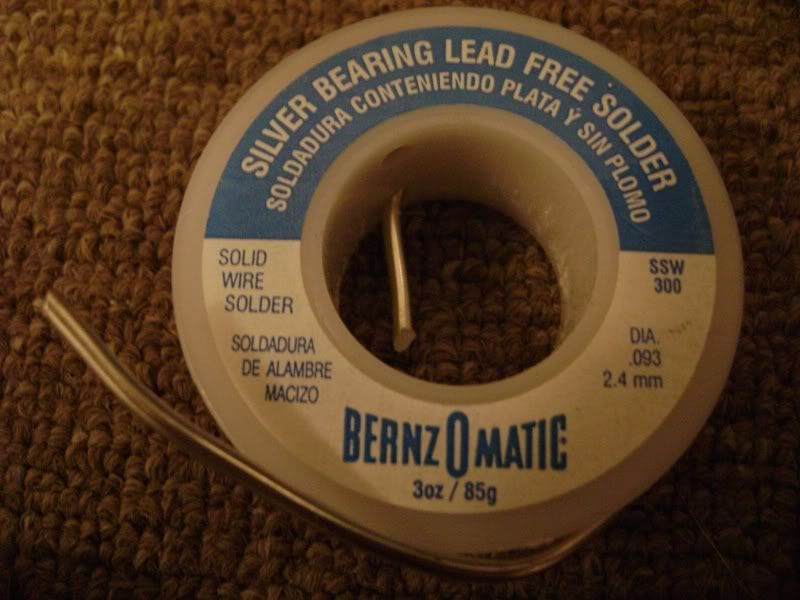

this is the solder

and this is my result

to me it doesn't really look like it flowed really well inside the joint and is not smooth at all around it (i did wipe it with a rag/my t-shirt when i was doing it to see if it made it smoother but it didn't really help )

Now onto the other sort of style (brazing?)

here is the rod and join in this picture

here is the flux that i dipped the rod into before applying it to the joint (i also tried this stuff on another attempt when using the soft solder above but still did not have success)

"this is a close up? I said a close up you jerk, a close up!"

from my recollection the brazing attempt looks like it has flowed a lot better around the join and would look sufficient to hold pressure.

So is it still a heat related thing with the soft solder or is there still something wrong.

All pipes and fittings are hit with emery paper/steel wool/deburring tool before fitting and heat application

-

12th December 2007 09:57 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

12th December 2007, 04:40 PM #17

Senior Member

Senior Member

- Join Date

- Jul 2007

- Location

- Sydney-south

- Posts

- 333

The silver looks OK, the soft looks like you've cooked it too well. Heat it gently, it doesnt have to glow, it only takes a few seconds to heat sufficiently, you will know if its hot enough because it will suck straight into the joint, you only need it just hot enough to melt the solder. If you want to have a look, cut the fitting in half with a hacksaw to make a cross section and see if the solder has made its way into the fitting.

Plumbers were around long before Jesus was a carpenter

-

12th December 2007, 04:58 PM #18

Senior Member

Senior Member

- Join Date

- Jul 2007

- Location

- Sydney-south

- Posts

- 333

Should look like this, photography isnt the best its off my phone

Attachment 62274Plumbers were around long before Jesus was a carpenter

-

13th December 2007, 08:58 PM #19

Are you sure that solder is ok for welding copper?, I've never seen it before.

If you dont play it, it's not an instrument!

-

14th December 2007, 07:36 PM #20

Senior Member

Senior Member

- Join Date

- Jul 2007

- Location

- Sydney-south

- Posts

- 333

Good point, but why would they bother with 'lead free'

Though the label says 'silver bearing' would that mean it has a content of silver????

Though the label says 'silver bearing' would that mean it has a content of silver????

But then again if they market the stuff with their little turbo torches they may be thinking that people who buy them are only going to weld some pipe or solder some copper wire together. Try using Coke as a flux, I havent tried it myself but a few of the old-hands say it works a treat.Plumbers were around long before Jesus was a carpenter

-

15th December 2007, 12:11 AM #21

Novice

Novice

- Join Date

- Nov 2007

- Location

- Adelaide

- Posts

- 17

i can't be certain on the solder but i assume it is, it also came with a strip of emery paper, just perfect for shinying up some copper tubing and a little brush. and like wonderplumb mentioned, why would bernzomatic release a kit like this if they didn't assume i was going to use it for soldering copper pipe.

i do have some other 'silver solder' that i bought from bunnings, it came in a blue blister pack and was a small coils worth, i'll try to find the packaging of it and post a piccie up of that as well.

I'll have another attempt this weekend (i might even try the coke as a flux thing for you if you like....i cant get the solder to look right anyway so why not experiment )

)

cheers for the help guys, this has been great

barnsey

-

15th December 2007, 12:03 PM #22

Dude, as far as I know I can't remember ever seeing copper tube solder at bunnies? Your in adelaide right? If you like I'll catch up with you and I'll give you some solder and sort you out on how to use this torch as well.

I know it's often a personal triumph to master a new skill all by yourself and Im in no way implying that your an idiot, just extending the arm of goodwill from one croweater to another. If you dont play it, it's not an instrument!

If you dont play it, it's not an instrument!

Similar Threads

-

Pipe clamps- the hunt and more

By soundman in forum HAND TOOLS - UNPOWEREDReplies: 55Last Post: 20th October 2006, 03:22 PM -

Australian Goverment Pipe Specifications

By trevorZ in forum WOODIES JOKESReplies: 1Last Post: 28th May 2003, 12:59 AM