Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 21

Thread: New toy

-

31st May 2013, 10:21 AM #1

Novice

Novice

- Join Date

- Dec 2012

- Location

- Kentucky

- Posts

- 19

New toy

New toy

I have wanted a lathe for quite a while. This weekend my uncle called and said he found one for me. If I could make it run, I could have it.

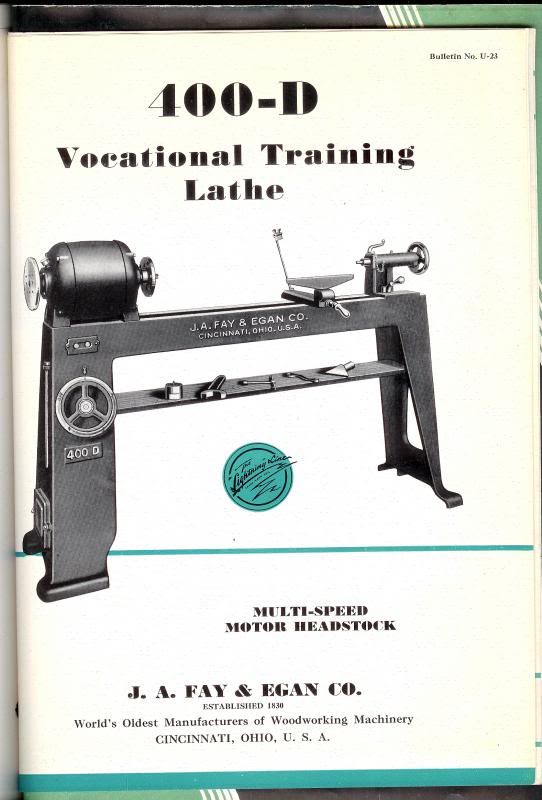

Its a j.a.fay egan lightening 400. It is in about 50 pieces, but looks to be complete. Does anyone have any info on the machine? Is it worth refurbing?

Thanks

ADDED BY ADMIN

DISCLAIMER

No liability is accepted by UBeaut or the Wood Working Forum's administrators

or moderators for advice offered by members posting replies

or asking questions regarding electrical work.

We strongly advise contacting a Licensed Tradeperson for all electrical work.WARNING

Information supplied within posts is not to be considered as detailed formal instructions to complete a task.

Members following such information do so at their own risk

-

31st May 2013 10:21 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

31st May 2013, 10:38 AM #2

Hi Quickchip,

Is it anything like this one.

http://www.penturners.org/olduploads...0_DSC03953.JPG

I did a quick google and found a few examples. While I have never heard of the brand before that one in the pick looks to be a solid well made machine and would be worth a bit of effort.

Regards

John

-

31st May 2013, 09:54 PM #3

If's it for free yes it's worth some time to see if you can fix it. Do continue to post along with progress photos.

-

1st June 2013, 10:11 AM #4

Novice

Novice

- Join Date

- Dec 2012

- Location

- Kentucky

- Posts

- 19

Re: New toy

Re: New toy

Well you guys made a good point. I should post pictures as I rebuild it. So here are the pictures of what I am starting from.

Well you guys made a good point. I should post pictures as I rebuild it. So here are the pictures of what I am starting from.

You should also understand the whole story. First there are two lathes not one. The motors are three phase 220v which neither of us have at our homes. There is also some sort of funky speed switching system involved.

The deal is, I tinker with them, get them working 220v single phase and I can keep one of them. So they are not totally free.

Right now the plan is to make sure the motors are good then hook the high speed coils to an inverter and start making cool stuff.

I would just change the motor but if you look closely you will see that the motor is some sort of direct drive set up so changing the motor is not an option.

Anyway here are the first pictures.

Sent from my SAMSUNG-SGH-I747 using Tapatalk 2

-

1st June 2013, 02:28 PM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2010

- Location

- shoalhaven n.s.w

- Posts

- 1,240

wow! I would make one long lathe out of them! hope you have some spare time! looks fun! even if you spend some dollars you will have the best set up!

-

1st June 2013, 03:48 PM #6

Senior Member

Senior Member

- Join Date

- Jun 2012

- Location

- Mosgiel New Zealand

- Posts

- 221

For what is worth heres my opinion. Have a think about how much you may have to spend as well as the time,do you have to make both into working order, then have a look around to see what a going second hand one would cost, contact a local club they may be able to help.the photos you have posted looks like a solid lathe apart from the headstock motor setup

but if you want a project go for it just be aware of the cost to value .dont be put off by one persons negative view its just that im a bit careful haveing been down the cheap way before.

but if you want a project go for it just be aware of the cost to value .dont be put off by one persons negative view its just that im a bit careful haveing been down the cheap way before.

Ian

-

2nd June 2013, 02:27 AM #7

Novice

Novice

- Join Date

- Dec 2012

- Location

- Kentucky

- Posts

- 19

Re: New toy

Re: New toy

Thanks for the comments. Right now I figure if the motors are good then I am simply a vfd from making chips, if not....might be a little more creativity needed.

The motor has 9 wires, almost like a 220-480 motor would have, but the plate only says 220. I am thinking it is wound like a 220-480 motor, and you get the variable speeds by putting the 220 power to the 480 coils to produce the lower speeds. Any of you guys have experience with a direct drive, variable speed motor like this?

ADDED BY ADMIN

DISCLAIMER

No liability is accepted by UBeaut or the Wood Working Forum's administrators

or moderators for advice offered by members posting replies

or asking questions regarding electrical work.

We strongly advise contacting a Licensed Tradeperson for all electrical work.WARNING

Information supplied within posts is not to be considered as detailed formal instructions to complete a task.

Members following such information do so at their own risk

-

2nd June 2013, 07:19 AM #8

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2008

- Location

- North Carolina, USA

- Posts

- 2,327

Quickchip,

It is possible the motors have three windings and are 3 speed. Delta connected 3 phase motors have 3 wires. The ground would go only to the frame. Look carefully on the plate to see if it gives speeds and phase.

Be very careful to be sure you have connected them correctly before you put electricity to them. If the magic smoke comes out it would be cheaper to buy a new lathe than to have the motor rewound.

Are you in Kentucky, USA or Kentucky, NSW, AU?

That bed and leg combination is wonderful. That will be a good lathe.

What is the center height from bed to the middle of the spindle?

I found this:

Photo Index - J. A. Fay & Egan Co. - "Lightning 400" | VintageMachinery.org

Fay egan - Yakaz For sale

Photo Index - J. A. Fay & Egan Co. - Model 400 | VintageMachinery.org

Photo Index - J. A. Fay & Egan Co. - 400? | VintageMachinery.org

One of the sites above says the lathe is a four speed. Make very sure about what your motors are before hooking anything up. Look carefully to see if there are any numbers on the wires.

I'll keep searching to find a wiring diagram.So much timber, so little time.

Paul

-

2nd June 2013, 10:05 AM #9

Novice

Novice

- Join Date

- Dec 2012

- Location

- Kentucky

- Posts

- 19

Re: New toy

Re: New toy

Thanks paul. Im in kentucky usa. It is in pieces but the center looks to be about 8 inches.

It is four speed ill post some pictures of the motor plate and the wiring diagram I sketched. The actual diagram was in a tight spot and couldnt get a picture. It does say it was drawn in 1930.

Sent from my SAMSUNG-SGH-I747 using Tapatalk 2

-

2nd June 2013, 10:25 AM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2008

- Location

- North Carolina, USA

- Posts

- 2,327

Fay & Egan Multiple Speed Motor

Fay & Egan Multiple Speed Motor

I found this:

4 speed motor help- wire ID?

I belong to the PM site. You may have to join to see photos. I have not ever had any bad junk come from being a member.

http://vintagemachinery.org/MfgIndex/Images/740-B.jpg

Photo Index - J. A. Fay & Egan Co. - 400? | VintageMachinery.org

Note: "The original switch gear was missing and the machine was a basket case at that time, however the 4 speed, 3 phase motor was still functional so I brought it back from the weeds."

You could use a VFD to run the multiple speed motor on the lathe as long as you shut down the VFD, changed the speed on the motor, and then ran the lathe with the VFD.

If you are in Kentucky, USA, once you are finished building your lathe, I would be interested in what ever is left of the second lathe. If you get discouraged I would consider trading a plug and play Hegner 175 for what you have.

My Hegner is like this, but with a solid bed. 13 3/4 inch / 350mm swing, around 36 inches between centers:

http://houtdraaienindehaarlemmermeer...shoparie_1.jpgSo much timber, so little time.

Paul

-

2nd June 2013, 10:36 AM #11

Novice

Novice

- Join Date

- Dec 2012

- Location

- Kentucky

- Posts

- 19

Re: New toy

Re: New toy

Paul

So I can use a vfd, but cant switch the speed with the motor running?

I owe the second lathe to my uncle, but he may want to sell it ill let you know.

Also what did you mean by pm site?

Sent from my SAMSUNG-SGH-I747 using Tapatalk 2

-

2nd June 2013, 10:47 AM #12

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2008

- Location

- North Carolina, USA

- Posts

- 2,327

You were posting while I was writing. The diagram is a gold plated gift. It would be most interesting to put together without it.

There is nothing like lots of cast iron in a lathe. You have a good one, or two if there is enough stuff to go around.

I don't know how knowledgeable you are about old motors and mechanical stuff. I hope I am not insulting you with my suggestions.

Old motors often will have leads with the insulation crumbling off. Heat shrink tubing slid over the old wire and heated with a hair dryer will save that. If you are skilled, you can go back to where the wire is coming out of the winding and solder new wires in.

I have read in Practical Machinist the procedure for cleaning and putting an old motor back in service. Just did a quick search and can't find it. 3 phase motors are easy, rotor, stator windings and housing. No capacitors or start winding and centrifugal switch.So much timber, so little time.

Paul

-

2nd June 2013, 11:02 AM #13

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2008

- Location

- North Carolina, USA

- Posts

- 2,327

VFDs do not like anything between them and the motor, I think if the flow of electricity is interrupted it blows the VFD. The VFD varies the speed of the motor, but if the motor is using a fan to cool itself, when you run motor slowly it gets hot.

I turn mostly bowls. On the 5 speed Hegner the slowest speed is 800 rpm. I usually do the whole bowl at that, if it is a smaller one with soft wood, once I have gotten it roughed out I might go to the next speed - 1400 - to finish. With spindles, as I am mostly using split logs, I do the same. Once or twice in 5 years I have gone up to the 3rd speed.

My 20 inch swing Woodfast has variable speed and 5 speed pulley set. I start very slowly in first speed with big out of balance blanks, go up in speed using the variable, then go to the second pulley and vary the speed to suit.

There are great discussions about using VFDs on old motors not made for VFDs. My take on it is if you are using the VFD to run the motor from 50% to 125% of the plate RPM you won't get into trouble.

Practical Machinist site: Practical Machinist - Largest Manufacturing Technology Forum on the Web

Forum on motors and VFDs: Transformers, Phase Converters and VFDSo much timber, so little time.

Paul

-

2nd June 2013, 07:26 PM #14

They are nice Lathes, pretty sure they are 400 D's.

Melbourne Matty.

-

2nd June 2013, 11:07 PM #15

Novice

Novice

- Join Date

- Dec 2012

- Location

- Kentucky

- Posts

- 19

Re: New toy

Re: New toy

Ls

I agree everything I see points to the machine being a 400 d. Even found a place to register their serial numbers. I might do that once they are running.

Sent from my SAMSUNG-SGH-I747 using Tapatalk 2

Likes:

Likes:

Reply With Quote

Reply With Quote