Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 21

Thread: My new workshop setup and lathe

-

4th July 2008, 04:54 AM #1

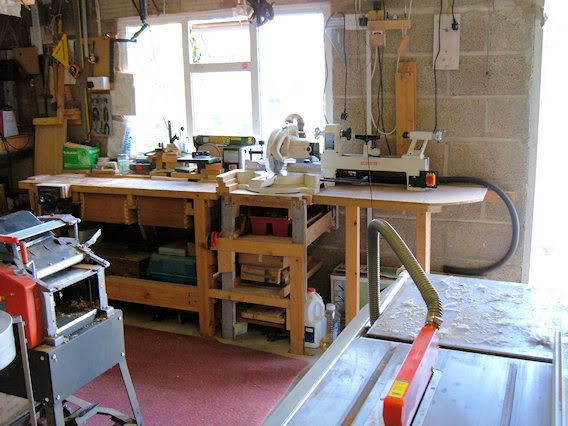

My new workshop setup and lathe

My new workshop setup and lathe

When not in use, lathe is positioned against the wall out of the way of the SCMS saw.

When intended to use lathe I will drag it forward to this position.

At he present moment the lathe rocks so I don't know at the moment if the castings is twisted or my bench is at fault. I intend to investigate again tomorrow afternoon.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th July 2008 04:54 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

4th July 2008, 07:19 AM #2

Looks very nice, only your bench top is not sturdy enough. My suggestion, take a 40mm tabletop for that. Make a sturdy frame and screw the table top on it. I did the same with my lathe.

Look to my website. http://members.lycos.nl/adecrom

Ad

-

4th July 2008, 07:28 AM #3

Hello John, nice peek at your shed. I concur with Ad's answer. You bench has to be rock solid. Mine is bolted to the wall in two places and somewhere around the 30 - 40mm thick. Maybe a reorganization of the shed with the obligatory photos?

Pat

Pat

Work is a necessary evil to be avoided. Mark Twain

-

4th July 2008, 08:32 AM #4

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Good setup Jow.

-

4th July 2008, 09:49 AM #5

I thought at first that you ment it rolled back against the wall but it seams you just push it back out of the way,

You will not get anywhere with a lathe that is not bolted down to a bench of some kind, even a small lathe needs to be secured down and a good solid surface, as for rocking i should think that one of the legs is a little smaller in the casting rather than a twist, this can be packed and bolted down. Bolt it down to a solid surface one that is going to stay still or you will just get

LB

LB

-

4th July 2008, 10:12 AM #6

Banned

Banned

- Join Date

- Jun 2007

- Location

- Otautahi , Te Wa'hi Pounamu ( The Mainland) , NZ

- Age

- 69

- Posts

- 2,114

Jow , the 'twisting ' is more likely to be in the table top , rather than the lathe.

A 20mm top is no workbench top at all . Add to that ,the frame it sits on is also lightweight .

It would be better , in the short term , to bolt it down to your heavy workbench , with long bolts and wing-nuts .

A new bench , the same size and weight , looks as tho it would fit along the wall , to carry both the drop saw and the lathe.

Try the bolt-down to your excellent workbench first , and see if there is a difference .

I hazard a guess that there will be .

Great workshop there mate , top toys too

Jock

PS. don'tworry about the holes left in the big bench , they may come in handy for bench dogs someday

-

4th July 2008, 11:41 AM #7

As the others have said the bench has to be solid and the lathe has to be secured to it. Most of the turning books have a section on constructing a bench. We are looking at legs at least 4''x4'' (laminate 2 2x4 if you have to) and the top at least 1 1/2''(2 sheets of ply MDF or chipboard can be glued to make this). It does not have to be a work of art just solid and heavy.

-

4th July 2008, 02:46 PM #8

Agree with all the above. My Little Vic sits on a table made from 13 2x4s screwed and glued together on edge. About 19 or 20 inches wide, and very sturdy on it's 2x4 legs. I just clamped it down, because I move it to my truck when traveling.

Al

Some minds are like concrete thoroughly mixed up and permanently set.

-

4th July 2008, 05:36 PM #9

Thanks for all advice mentioned above, a nice new 10ft workbench across that site would be nice.

And purchase a new carpet as well!woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th July 2008, 08:28 PM #10

Banned

Banned

- Join Date

- Jun 2007

- Location

- Otautahi , Te Wa'hi Pounamu ( The Mainland) , NZ

- Age

- 69

- Posts

- 2,114

Na mate , carpet is a bugga to vacuum , best stick with the lino

-

4th July 2008, 09:09 PM #11

woody

woody

- Join Date

- Dec 2006

- Location

- werribee

- Posts

- 276

John I reckkon a thicker bench top but also like yo there is more than one thing happening on my bench area and when the lathe comes in to play I put 2 layers of antislip down and she will sit while I turn for a couple of hours and not move and also reduced the noise considerably so will leave it to you to use the idea if you wish regards WW Wally

-

4th July 2008, 11:12 PM #12

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

5th July 2008, 01:22 AM #13

So, what do you fancy trying your hand at?

If only small stuff (small, as in "not the maximum sizes that lathe will handle") like pens, etc. then there's no need to bolt it down. As WWWally said, a rubber mat does the job nicely.

Mind you, you'd be surprised at how big a piece of wood it will spin up... and if you plan on finding out just how big then it'd be a very, very good idea to invest in a couple of bolts. DAMHIKT!

- Andy Mc

-

5th July 2008, 01:48 AM #14

Thanks for the encoureagement Skew.

The preseent lathe bed is only 15mm chipboard, but everything is screwed to the back wall and the floor also to the side bench, and braced underneath I can get no vibration at the moment.

Going to have a go tomorrow, a neighbour is requesting my services to reset her broadband.

And I gather their helpline is useless!woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

5th July 2008, 02:01 PM #15

Deceased

Deceased

- Join Date

- Jun 2003

- Location

- ...

- Posts

- 7,955

Nice setup John, but isn't it time you painted the walls white?

Peter.

Similar Threads

-

Lathe vacuum chuck setup

By Fredo in forum WOODTURNING - GENERALReplies: 20Last Post: 25th April 2008, 08:35 AM -

So if I'm going to buy a full lathe setup.....

By Hardenfast in forum WOODTURNING - GENERALReplies: 17Last Post: 29th March 2007, 01:49 PM -

Jet setup problem.

By old_picker in forum BANDSAWSReplies: 15Last Post: 19th October 2006, 11:40 AM -

New JET 14" setup

By TassieKiwi in forum BANDSAWSReplies: 15Last Post: 7th July 2005, 07:04 PM -

Lathe setup

By MJ in forum WOODTURNING - GENERALReplies: 4Last Post: 17th May 2000, 08:15 PM

Reply With Quote

Reply With Quote