Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 52

Thread: Chevron box

-

15th April 2008, 09:20 PM #31

Box is looking good John, very interested seeing the different conditions that people work under on the other side of the world, I can't even get my head around that sort of cold

Peter.

-

15th April 2008 09:20 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

15th April 2008, 10:32 PM #32

Segmented boxes eh, got a lathe?

....................................................................

-

15th April 2008, 10:36 PM #33

-

16th April 2008, 10:07 AM #34

Good to see some work happening

Jow

Jow

Maybe the forum should go down more often

poms will make any excuse not to work

To Hot, To Cold, not enough beer in the fridge

-

16th April 2008, 05:48 PM #35

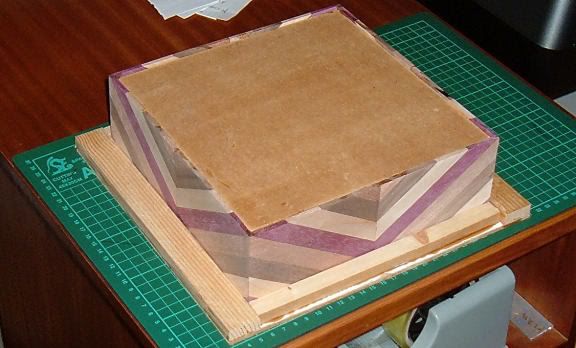

Got an MDF base fitted which I might veneer at a later date after looking at pictures this morning. The sides have sanded down quite nicely and mitres are reasonable if not perfect. I might insert angular supports at each internal corner because I have most probably sanded down to 9mm thick timber.

Making a former for the top lid as per photographs below.

The box upended and fitted into the former, this should ensure the lid comes out to size and fit.

More delays, car going up the repair shop. etc.etc.

Being retired I seem to have no spare time for anything hobbywork these days. woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

16th April 2008, 06:37 PM #36

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Getting along nicely!!

-

16th April 2008, 09:36 PM #37

Its 45 degrees far. beautiful blue sky, no wind, no complaints this morning.

But I have run into trouble with the lid for the box.

Started preparing for setting up chevron design top and feeling a bit despondent about the preparation.

End grain joins are going to be needed all over the place.

So putting aside for the moment, I might consider a marquetary pattern chevron finish over a lid base.

In addition took delivery of an air filter this morning and opened the box and case and found this. The electric motor casing is split open and completely u.s.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

17th April 2008, 08:54 AM #38

Damn john, sorry to hear about your air filter. Thats gotta ???? u to tears.

-

17th April 2008, 05:51 PM #39

The good news is that the suppliers are replacing the air filter today. That means I shall have a day tied up making a frame to hold the airfilter to the workshop rafters.

Feeling a bit more confident about the chevron pattern lid for box, I think I am definately going the marquetary route.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

1st April 2009, 06:39 PM #40

Do you remember this box, the project was dumped April 08, last year.

I intended to proceed with the chevron box design across the lid, I did make one or two attempts during 2008 but I could not get a decent match of lid to carcass.

Also there as been some movement with carcass timbers, they are inclined to fall in to the box, so there is a not perfect straight rim.

So I have succumbed to making a plainish lid.

Drew a template around box top rim on a piece of paper.

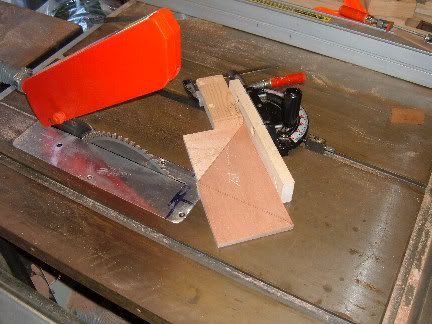

I am going to try and make the lid up of 4 segments, this picture shows the first section of timber cutting a 45% angle segment.

This picture shows me packing out the tablesaw mitre gauge runner withtwo thicknesses of paper to stop slop on this lefthand side runner, (the r/h side is OK)

Three section fitted up OK, the fourth failed, (I will remake a final piece today)

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

1st April 2009, 07:10 PM #41

Glad to see you and the box back, John. The weather that bothered you so much during your earlier work was a &^&^%# pest - how are you travelling now?

soth

-

2nd April 2009, 06:40 PM #42

Our Spring weather here in the UK is good this year.

_______________________________________________________________

So I have had to search around for some timber for the final section, and I went to my very depleted secret timber storage area where I knew there might be the last length of Br. Mahogany.

2.2mtr br.mahogany x190mm wide on the chop saw bench and a 60cm length removed.

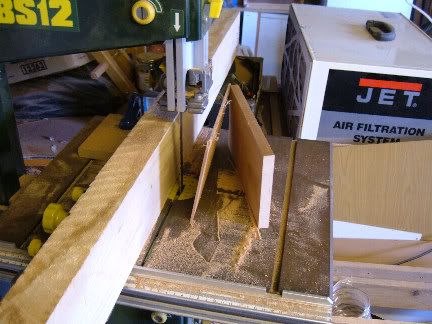

Over to the bandsaw to do a resaw jobbo, I put a heavy piece of ash against the bandsaw fence and also I clamp a steadying lump on the back side of the fence so nothing moves except what is called for.

It really makes a difference clamping that block to the table top on the back side of the fence, because when I am cutting on the bandsaw, I use two push sticks, one at the side of cut timber by blade and the other working the timber through the blade.

Cut the last portion of lid on the tablesaw and had to make final adjustment using a handplane.

Glued in the final section.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd April 2009, 05:59 PM #43

Dissatisfied with lid design so have put the lid piece away for use sometime on another idea.

So found a piece of 3 mm ply and cut to size to fit top of box, also glued on formers under lid to stop bowing of this cheap bit of timber.

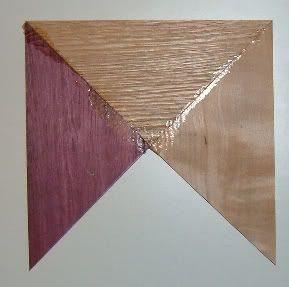

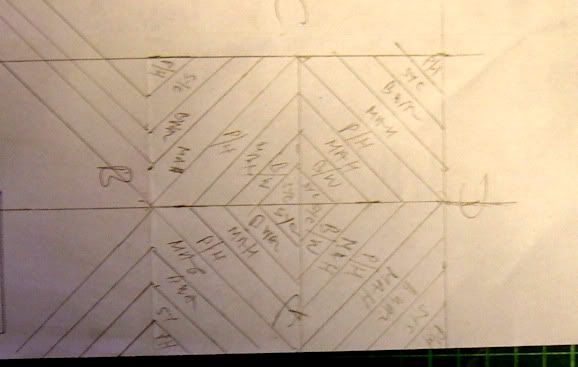

Found hopefully sufficient matching timbers to maintain chevron design for lid.

This is a drawn plan designating which timbers and positions required .

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

5th April 2009, 06:05 PM #44

Had a good day, and my enthusiasm for this box has returned.

Used a couple of straight edges and glued up the first two pieces in position, (its like laying paving slabs, much much lighter work) Had to leave them to dry quickly and the warmest place in the daytime is our conservatory, reaches over 90F this time of the year, so pieces set up in the hour.

the first row on.

and another row

building up nicely, and the days work

I will have to have a lip moulding around the outside edge to make the lid work, the ply is developing a bow again.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

5th April 2009, 06:43 PM #45

I like the way you're lining up the timber types to match the side panels. Should make for an interesting effect when done.

I can't tell whether you've already fitted a base to it... if you haven't do you think you'll be carrying the idea of the lid design through to down there as well?

- Andy Mc

Reply With Quote

Reply With Quote