Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 5 of 5

Thread: New Gun Case Design

-

26th December 2009, 06:06 PM #1

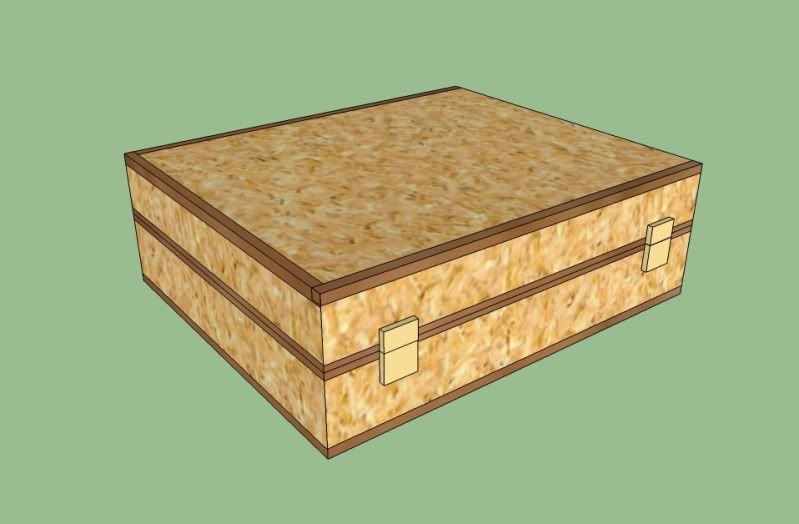

New Gun Case Design

New Gun Case Design

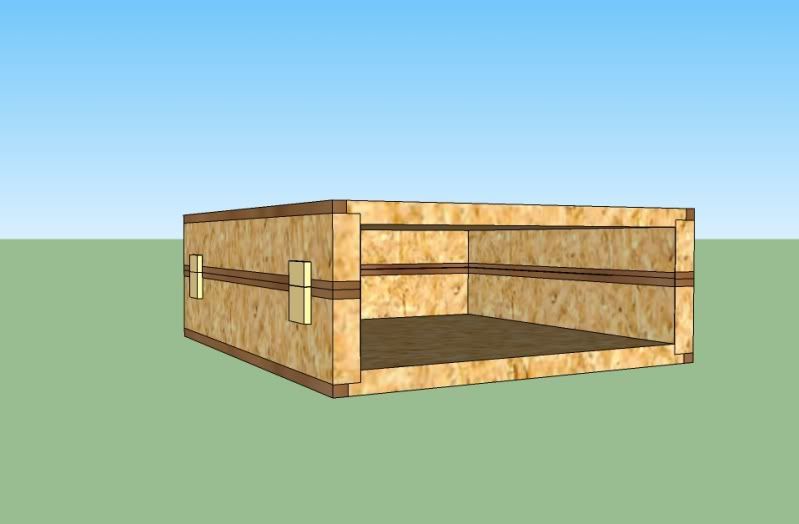

I am thinking of using a simpler design on my gun cases. My current design is very stong but it has proven to be hard to get the upper and lower sections to align. In my old design the upper and lower section are of a different design. While this makes for a nice contrast it also makes it extremely difficult to make sure that the align properly once glued up. To solve this I am thinking of using the design shown below where I glue up the entire box as one unit and then seperate the upper and lower by cutting the box in half.

Any suggestions or thoughts would be welcome.

-

26th December 2009 06:06 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

26th December 2009, 07:44 PM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2003

- Location

- Sydney,Australia

- Posts

- 3,157

Make the box, then cut it open has pretty much always been the preferred option, at least if my Grandfather was to be believed - and he apprenticed as a box maker about 1900.

-

27th December 2009, 05:44 AM #3

At least cut all the pieces and make sure everything matches before glue up/assembly. But I agree that separating the top after is probably the most foolproof.

-

27th December 2009, 06:43 AM #4

I do a pretty good job of cutting all the pieces and getting them matched up before assembly but it seems like there is always something that causes me issues. A 1/32 of an inch here and another 1/32 of an inch there and pretty soon you're talking an 1/8 of an inch out of true.

Also I currently use mini-biscuits to join the pieces but in this design I'm using rabbets. The biscuits make for a very strong joint and I'm hoping that the rabbet joints will be strong enough. Maybe I should drive some dowels through just to make sure.

-

27th December 2009, 08:21 AM #5

As Bsrlee says, making in one piece and cutting is the traditional method & works well.

Rabbet joints are not terribly strong without dowels, especially for a box that size, because one part of the joint is always end grain. You would be better off using either a finger (aka box) joint or dovetails. Finger joints can be done either on the bandsaw or tablesaw, or by hand.

Similar Threads

-

Finding Engineering Design Software For Automatic Machine Design

By davidWilliams in forum METALWORK FORUMReplies: 2Last Post: 11th January 2010, 10:41 PM -

Pen case

By dj_pnevans in forum WOODTURNING - PEN TURNINGReplies: 2Last Post: 9th June 2009, 12:45 PM -

pen case

By thefixer in forum WOODTURNING - PEN TURNINGReplies: 11Last Post: 7th June 2009, 01:07 PM -

In case you like this...

By mbirnios in forum Links to: WEB SITESReplies: 0Last Post: 11th October 2008, 05:03 AM -

Novel PC case

By Guy in forum WOODWORK PICSReplies: 0Last Post: 7th September 2006, 11:12 PM

Reply With Quote

Reply With Quote