Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 76 to 90 of 137

Thread: A Few Projects To Share With You

-

7th December 2007, 05:07 PM #76

Where do we find the time and money for these builds ?

It's easy..........you've just gotta look in the right places

cheers, Stu

-

7th December 2007 05:07 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

8th December 2007, 01:57 AM #77

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2007

- Location

- sydney

- Age

- 35

- Posts

- 580

id say their good for what they want to be, but im nolonger interested in a heavily overwound pickup with a ceramic magnet. it has huge bobbins, might make a pup using a bit heavier gauge magnet wire, so it fills the bobbin, but has less output (which would be better for sensitivity and such) and then replace the magnet with a alnico one. might not though.

-

12th December 2007, 10:18 PM #78

Ethereal, got anything for us?

You wouldn't have a few necks glued onto certain bodies by any chance ???

craving a few pics is all.

craving a few pics is all.

cheers, all

-

13th December 2007, 01:55 PM #79

More updates to follow shortly Oz

. I am finalising the sanding on 2 builds and hope to have necks glued in the next few days. I have taken up one of your steps and chosen to wipe a thinned out blonde shellac mix on the body and neck prior to glueing.....will allow easy removal of glue overflow from the join....also keeps the wood work nice and clean.

. I am finalising the sanding on 2 builds and hope to have necks glued in the next few days. I have taken up one of your steps and chosen to wipe a thinned out blonde shellac mix on the body and neck prior to glueing.....will allow easy removal of glue overflow from the join....also keeps the wood work nice and clean.

Stay tuned fellow luthiers

-

14th December 2007, 07:49 PM #80

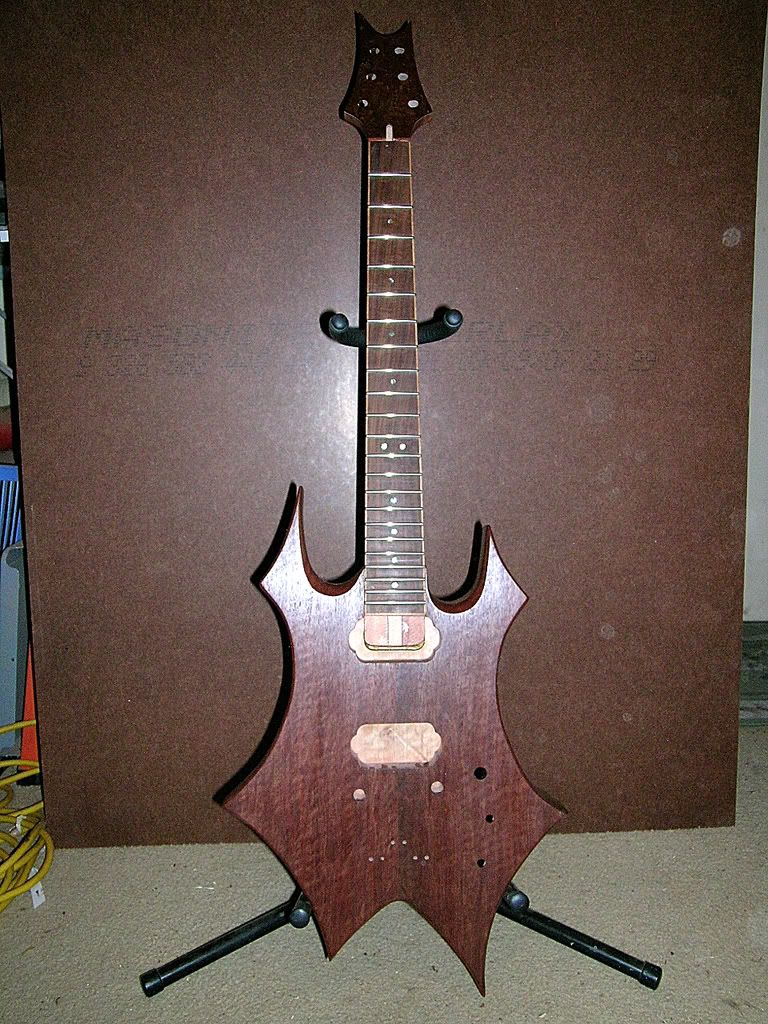

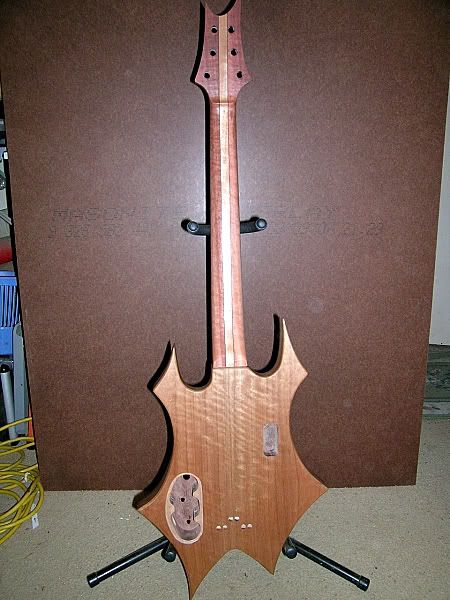

OK. Bit of progress this week. This build is the second of my metal series "Conjurer" shape. Really happy with this build so far. QLD Maple body with mildly figured Jarrah top. Black spot Jarrah neck with centre QM laminate, Gidgee FB and Minnerichi headstock veneer.

I have a set of Seymour Duncan "Blackouts" 9v active pups for this build, black hardware, tom with stringthru etc......

I'm hoping the QLD Maple and Jarrah will prove to be a nice tonal combination....the Gidgee FB is nice and hard and should add a nice snappiness to the tone......

So far, just a wipe over of thinned out blonde shellac.....nitro finish coming up soon......

-

14th December 2007, 08:21 PM #81

Man, that spotted jarrah on the neck gets me every time !!!! superb.

Beautiful neck timber combos. Nitro will make that spotted jarrah look nuts.

Can't wait to hear this baby with the actives in it.

-

14th December 2007, 10:44 PM #82

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Sydney

- Posts

- 489

Hi,

Nice combo of timbers. Just out of curiosity, why the shelac under the nitro? Is it to replace sanding sealer? Or does that go on as well?

Again, nice build. Original.

Peter

-

14th December 2007, 11:04 PM #83

G'day Peter.

The thinned blonde shellac is used in this instance as a sanding sealer.

When grainfilling is required, you can apply the thinned shellac coat prior to using your slurried timbermate grainfill, then once grainfilling is achieved, you can apply more thinned shellac to seal off before hitting with nitro.

I also use blonde shellac as a preservative on my builds between stages of building. Especially when excessive moisture can discolour timbers a bit.

Basically keeps things nice and clean and seals it off from the nasties.

It also is a good approximation of the colour achieved after shooting clear.

Is that your take on it also, Ethereal ?

(sorry to answer your questions)

(sorry to answer your questions)

cheers, Stu

-

14th December 2007, 11:47 PM #84

Thanks for chiming in OZ

couldn't have answered better myself! Thanks for the comments Peter....

couldn't have answered better myself! Thanks for the comments Peter....

-

15th December 2007, 09:55 AM #85

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Sydney

- Posts

- 489

Thanks OZ & Ethereal,

Sounds like a good idea, might give it a try with a nitro finish (itching to try). I've used linseed oil and danish oil for the same purpose (to protect the timber during a build), but only when the finish is going to be an oil & wax finish. I've found sometimes waiting about 2 weeks after finish sanding before applying oil, gives better depth of colour. I think it's the natural oils in the timber rising slightly to the surface. Not sure exactly. It's only subtle. Would the same apply to a nitro finish? I suppose the shellac would enhance the colour of the timbers also?

Cheers,

Peter

-

15th December 2007, 10:40 AM #86

Oz has a heap of experience in spray painting and finishing in general and really is the guru on the topic as far as I am concerned.

I have experimented with several methods. I have used a standard pre-mixed shellac finish in the past and this is good when you want to add a bit of darker tone to the colour.....the blonde shellac is pretty much clear and seals the timber and highlights the natural colours. The great advantage to me with shellac sealer is that it dries so quickly, sands easily and looks good. I have read that it is good practise to 'wet' the timber with water when final sanding as this will 'raise the grain'.....then once dry, apply the sealer coats.....this may speed up the 2 weeks you are referring to whilst waiting for the natural moisture in the timber to surface.

I have 3 builds on the go which will all have the same finishing procedure of shellac sealer, grainfill, shellac sealer, nitro. I will be learning a lot over the next couple of months

-

17th December 2007, 11:13 AM #87

Guitarzzz

Guitarzzz

- Join Date

- Aug 2007

- Location

- Melb

- Posts

- 162

Nice looking axe there Etherial. Love the look of that neck. The contrast of colours is magnificent.

-

17th December 2007, 12:15 PM #88

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Dec 2007

- Location

- yarra valley

- Posts

- 683

hey blokes just reading some of your posts and noticed alot of you like to use blackwood. I run a weekend sawmill ,not my full time job but takes up alot of weekends so if you blokes are looking for blackwood I might have some you might be interested in from qtr sawn to slabs of the stuff and i dont charge as much as mathew's. any way if your interested let me know and we might be able to do something. just to give u an idea, brad from cole clarke guitars wont buy alot of my timber because i cant supply the amounts he needs to produce consistent guitars, he,s knocking out more than 70 units a week.I'm also around on weekends and after hours.if any of you blokes make accoustic guitars i've got three norfolk island pine logs in the yard i'm yet to cut up but they are a cousin to bunya bunya pine which brad uses for backs and i'm interested if it could be substituded for this

-

17th December 2007, 07:06 PM #89

Sounds great Charlsie. I'd be very keen to catch up and see what's on offer. Yarra Valley sounds good to me, about 20 minutes away! I go up to Millgrove and see Tim up there every so often and know the area very well. Send me a PM if you like and we'll correspond further. Thanks for the offer.

Thanks for the positives Hammered ....I really like the jarrah QLD Maple contrast, kinda sets both colours off nicely....cheers.

....I really like the jarrah QLD Maple contrast, kinda sets both colours off nicely....cheers.

-

18th December 2007, 10:21 AM #90

Guitarzzz

Guitarzzz

- Join Date

- Aug 2007

- Location

- Melb

- Posts

- 162

No worries mate. It's a nice unique design. Obviously similar to a warlock, but you've got your own twist on it, and it works IMO. You should have called it the "Grand Conjuration"

I agree, the jarrah/QLD maple does contrast very well. I'm also a fan of the blackwood/QLD maple combo, which is what I'm planing to use next, once I finish off a few other little projects.

Similar Threads

-

woodworking projects for child

By kaeita in forum WOODWORK - GENERALReplies: 24Last Post: 7th October 2007, 11:13 PM -

School Projects

By Hagrid in forum WOODWORK PICSReplies: 16Last Post: 25th June 2007, 05:55 AM -

My first projects

By diamonds in forum WOODTURNING - GENERALReplies: 6Last Post: 16th July 2006, 09:06 PM -

A few humble projects...

By Darknight in forum WOODWORK PICSReplies: 4Last Post: 2nd March 2005, 11:35 PM -

Share Accommodation Available Rural Qld

By paeon in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 2Last Post: 6th July 2004, 09:53 AM

Reply With Quote

Reply With Quote