Thanks: 0

Thanks: 0

Results 496 to 510 of 527

Thread: Show us your Shaper

-

30th May 2013, 11:05 PM #496

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- Sydney

- Posts

- 178

Hi Leroy,

Can't give you a guide to year of manufacture, but having plain bearings and the makers name moulded as part of the ram casting indicates it is not the more recent series. Nor its it the earliest type, which had no provision for a front support. AFAIK the clutch was an option, and not indicative of the age of a particular machine.

Congratulations - it looks quite complete and really good for its age!

Cheers,

Bill

(Edit) Just remembered a discussion about the age of a Douglas: starts at post 20 - https://www.woodworkforums.com/f65/do...07/index2.html

-

30th May 2013 11:05 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

5th June 2013, 05:44 PM #497

Douglas shaper

Douglas shaper

Well last week I received my shaper and thought it looked good for its age now after some time with paint and kerosene its

looking even better, if anyone has some spare handles I'd like to hear from you, also if anyone knows where that washer belongs

I'd love to know,

Leroy .

.

-

5th June 2013, 06:50 PM #498

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2011

- Location

- sydney

- Posts

- 880

HI,

Like your new paint scheme. Looks great.

Ben

-

5th June 2013, 07:47 PM #499Dave J Guest

I would say that washer is off something like the pulley shaft or some other shaft back there.

Dave

-

7th June 2013, 11:49 PM #500

Intermediate Member

Intermediate Member

- Join Date

- Dec 2011

- Location

- North Rocks

- Posts

- 47

Show us your Shaper

Show us your Shaper

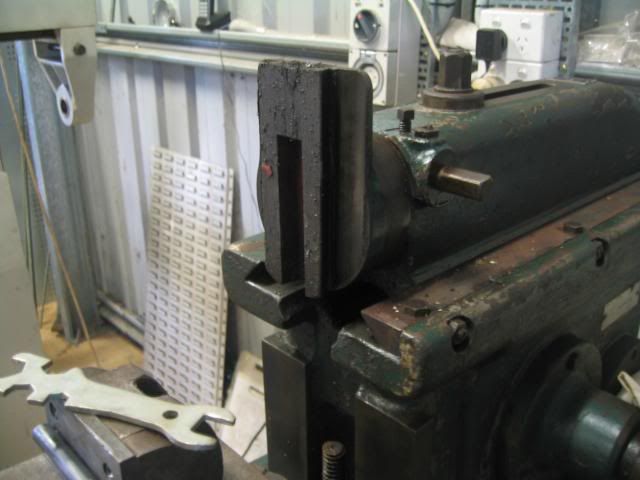

Well I waited, but not too long, and thanks to a connection made through a member here, thanks Peter(Bollie7), I am now the proud owner of a Douglas shaper.

ImageUploadedByTapatalk HD1370608579.151864.jpgImageUploadedByTapatalk HD1370608602.086316.jpgImageUploadedByTapatalk HD1370608647.485018.jpgImageUploadedByTapatalk HD1370608671.265889.jpg

Picked it up in Newcastle and dragged it home much to wife's annoyance. I have looked at numbers but still not sure of the year? 65? There is no front table support, no clutch, no handles, no vice, motor belt is quite loose, motor wires chopped off less then 10 mm long. But wear wise it looks good. I do have another belt guard. Most of this i can probably sort given time.

But it has a broken tooth on the table feed gear and that probably exceeds my current confidence level as far as repair goes. The shaft it sits on is slightly bent too but I think is ok or can straighten.

ImageUploadedByTapatalk HD1370608778.550617.jpg

So any one have a spare gear or vice or front support, or handles?

Or advice on other suitable vices, repair etc

Thanks

james

Sent from my iPad using Tapatalk HD

-

9th June 2013, 10:52 AM #501

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

Skip to 5:30 to see an old worm-drive shaper running.

Watervliet Arsenal Museum Machine Shop - YouTube

-

9th June 2013, 11:09 AM #502

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

And with thanks to google and PM here is how it works.

Patent US436139 - SHAPING AND SLOTTING MACHINE - Google Patents

-

9th June 2013, 03:19 PM #503

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2011

- Location

- sydney

- Posts

- 880

-

9th June 2013, 03:48 PM #504

Hi James,

I'm not sure about a vice, but I'm sure the front support could be made fairly easily, same with the handles.

The ratchet gear needs to be made with a dividing head or RT on the mill or shaper. What dimensions/teeth no. etc is it? I probably owe a favor or 2 to Michael G and Matty G so i'll offer to make one for you if you haven't sorted anything else out.

Cheers,

Ew1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

14th June 2013, 12:05 AM #505

Hi. My Douglas had two teeth sheared off the table advance ratchet.

You will very quickly work out how this happens, by the way (Hint: don't tighten the T-slot nut too tight on the rechet arm excenter).

(Hint: don't tighten the T-slot nut too tight on the rechet arm excenter).

Anyway, I ran a couple of careful beads across the ratchet wheel with my arc welder and carefully filed them back to shape. Took maybe half an hour and is pretty undetectable. It works just fine.

Good luck.Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

-

10th September 2013, 03:06 PM #506

Senior Member

Senior Member

- Join Date

- Feb 2013

- Location

- Laidley, SE Qld

- Posts

- 368

I showed this Alba 1A shaper on here a while ago, and now I can use a few words of wisdom about freeing the swivel for the vertical slide.

The swivel is stuck, I can get no movement at all out of the spindle. I've removed the 2 bolts from the RH side near the square drive, I've lubricated, I've tapped, now its time to get serious. After removing the clapper and vertical slide hoping to attack the problem from the front, it looks like I need to remove the ram to get in behind the swivel.

I'm sure that removing the ram and freeing the swivel is all pretty basic stuff, any words of wisdom before I start?

Thanks in advance

-

10th September 2013, 03:56 PM #507

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Bob,

I'm unclear on what the issue is.

Can you loosen the Square drive and the swivel wont move? or cant you loosen the square drive

Sorry if I'm being thick.

Stuart

-

10th September 2013, 04:17 PM #508

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

I might be thick too but on my little Douglas the clapper box swivel is fixed with a cam type "bolt" . You may be tightening rather than loosening the thing. A trap I fell into when I first tried to dismantle mine.

Bob.

-

10th September 2013, 06:45 PM #509

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2004

- Location

- Kyabram. Vic

- Posts

- 826

Bob,

IIRC the square shaft has a cam to tighten the swivel. I think that it works in reverse. IIRC the 2 studs on top retain the cam and shaft. Remove them and the shaft pulls out and then allows the the swivel head to pull out. To remove the ram remove the stroke adjusting nut on top of it. You will need to open the side door and support the "fork" so it doesn't crash down. (keep the fork well lubed at the top joint as there is a weakness there that will seize and cause a MAJOR crash. As in bent shafts, teeth off gears and possibly damaged cabinets) My old girl had had a major crash and had been repaired. I also had to have a new gear made due to missing teeth. Take off the adjustable dovetail and the ram will slide off. It is weighty.

I am working from memory from about 4 years ago and it could be a bit dodgy. The craft syndrome.

Kem

-

10th September 2013, 06:48 PM #510

To add to the two comments from BT and Stu: the square peg on the side is likely to be an excenter or a cam inside, turning it either way of a "neutral" position or angle will lock the head pivot.

Are you able to find a "loose" position for the square pin by turning it clockwise or anticlockwise a little? If you can, leave it there and see if you can tap the vertical slide base either way a little - or indeed 'forward', in a direction away from the ram (by a small amount to allow lubricant to penetrate into the swivel).

Let us know what you find.Cheers,

Joe

9"thicknesser/planer, 12" bench saw, 2Hp Dusty, 5/8" Drill press, 10" Makita drop saw, 2Hp Makita outer, the usual power tools and carpentry hand tools...

Similar Threads

-

shaper

By jonroe in forum METALWORK FORUMReplies: 3Last Post: 27th September 2011, 12:02 AM -

Shaper

By Anorak Bob in forum METALWORK FORUMReplies: 43Last Post: 19th March 2011, 10:18 PM -

TOS shaper

By Bryan in forum METALWORK FORUMReplies: 91Last Post: 16th March 2011, 05:58 PM -

Shaper vid

By .RC. in forum METALWORK FORUMReplies: 6Last Post: 1st October 2008, 11:03 PM

Likes:

Likes:  Needs Pictures:

Needs Pictures:  Picture(s) thanks:

Picture(s) thanks: