Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 10 of 10

Thread: Chisel Blade Testing - 5 Steels

-

15th May 2011, 03:47 AM #1

Chisel Blade Testing - 5 Steels

Chisel Blade Testing - 5 Steels

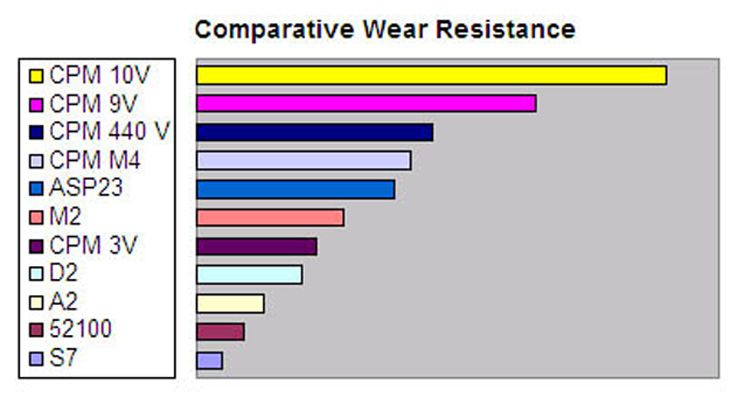

There has been considerable discussion about the merits of the "new" powdered metal super steels over the past year. Of course these are not new steels - they have been around quite a while and "old hat" to knife makers. However they represent new possibilities for woodworkers in the form of longer-lasting edges.

Longer lasting edges reflect high abrasion resistance, and the challenge with these super steels is to find an efficient and economical sharpening regime. Put away the Japanese waterstones, even the ceramic variety. Hide the sandpaper, and don't even admit to thinking that you may try oil stones .... none of these are effective. Yes, my Professional Shaptons do work, but ever so slowly, and you will be fooled (as I was) into believing that you have a working edge. The only medium that works effectively is diamond. I used diamond paste on a cast iron substrate with 40, 10, and 0.5 micron grits. With diamond, these steels were sharpened as easily as my A2 and laminated Japanese blades are on Pro Shaptons.

Using the above regime, all chisels easily pared Radiata Pine end grain as a pre-assessment screening.

The Steels

There are three powdered metal chisels, CPM 3V, CPM 10V and CPM M4. These blades were supplied by John Payne, who arranged for their heat treating.

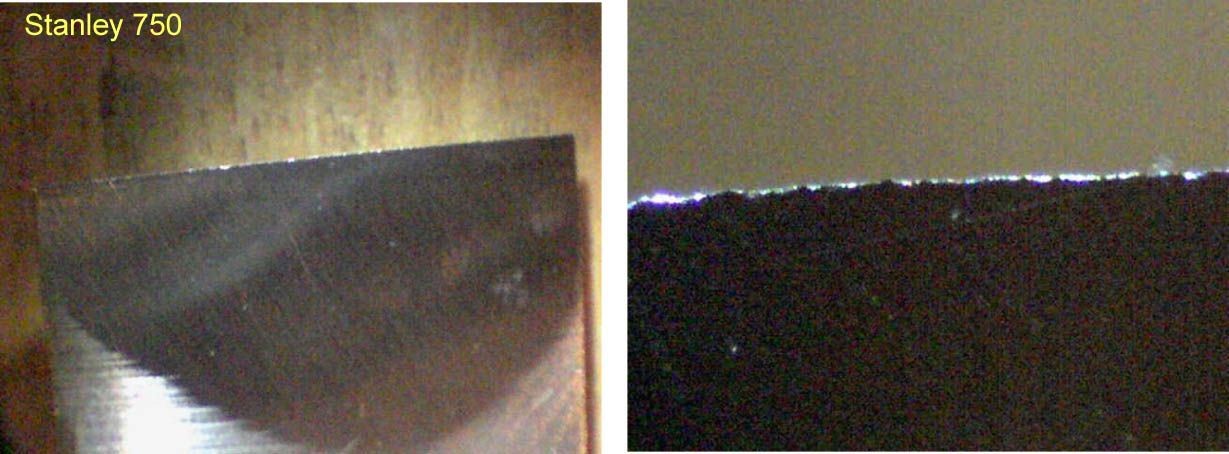

As a measure of control, I added a vintage Stanley 750 chisel, which is likely to be W1 steel. I also added a 30-year old Koyamaichi dovetail chisel, which I believe to be white steel.

Five 3/4" chisels: 3V, 10V, M4, W1 (Stanley), and Laminated White (Koyamaichi)

The Test

I wanted a Real World evaluation, and so took the opportunity to chop out the dovetail pins in a 3/4" thick Jarrah carcase for a cabinet I am constructing. Each pin was 45mm in length.

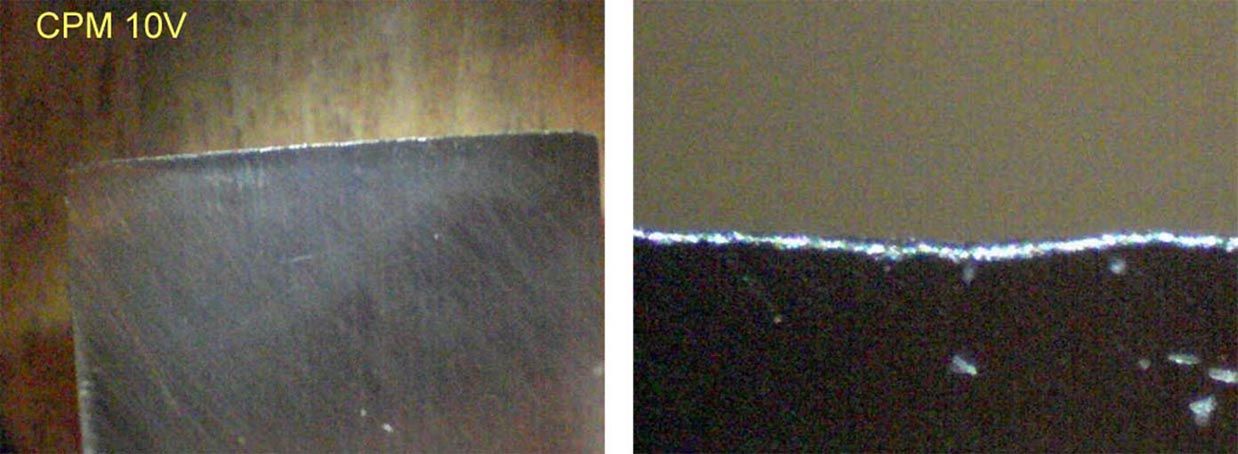

The method involved chopping out one half of a pin waste with each chisel in approximately 1/16" - 1/32" slices, checking the blade subjectively for a wire edge (by touch), testing the edge for sharpness by paring end grain Radiata Pine, turning the Jarrah board over and completing the removal of waste, and repeating the checks. At the conclusion, the blade edges were photographed at 200 magnification.

Half way ...

The Results

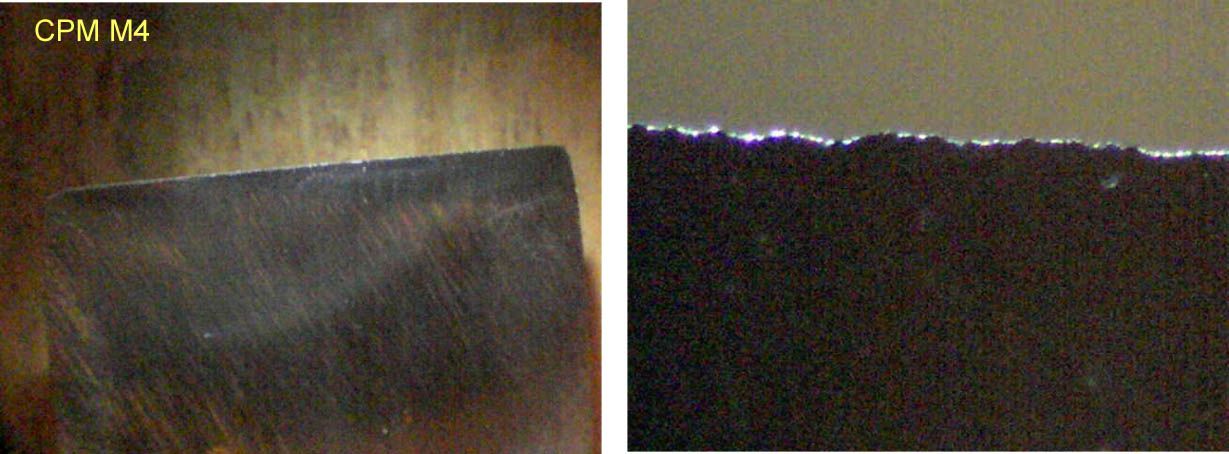

All the chisels were able to chop Jarrah waste even when the edges were dull. Few could pare end grain Pine comfortably after chopping the first half of the Pin waste, and only one chisel stood out as a tool of significant worth, the Koyamaichi. In second place was the M4 chisel, with the 3V coming in after this. The Stanley and 10V came in at the tail, with the Stanley just shading the 10V.

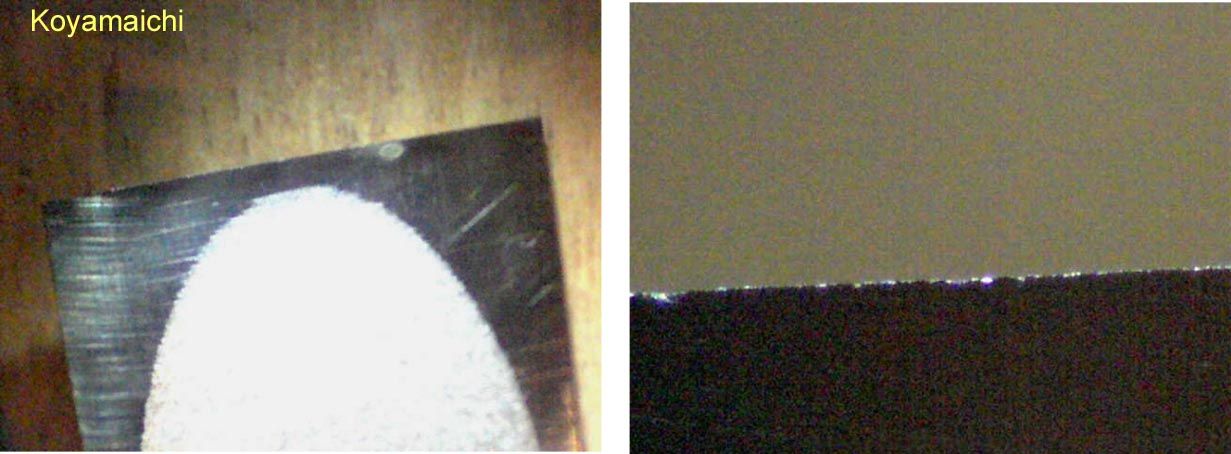

The Koyamaichi was outstanding. Not only did it fail to evidence signs of a wire edge (i.e. steel edge folding) at the half-way stage, but it was still paring end grain after 9 full dovetails. By contrast, only the M4 and 3V chisels were able to pare end grain at the end of a single dovetail, and at this stage they performed less well than the Koyamaichi did at the end of 9!

What of the Stanley? Well it did not disgrace itself and, in fact, did a very decent job. The 3V was tested initially with a 25 degree bevel (as this was the angle recommended). The Stanley (also with a 25 degree bevel) was better than the 3V in all departments (edge holding and performance) at this stage. However the 3V improved significantly when the bevel angle was increased to 30 degrees.

The Koyamaichi, M4 and 10V were given 30 degree bevels at the start (all recommended angles). This appears to be a good choice as the latter two blades developed only a fine wire edge. The wire edge on the Koyamachi was difficult to find.

Images

The images are in a set of two, with the first a magnification of 10X of the back of the blade, and the second image a magnification at 200x.

Koyamaichi ...

M4 ...

3V - note that the top images are with a 25 degree bevel, and the lower at 30 degrees ...

Stanley 750 ...

10V ...

In Summary

Relatively better performances from 3V and M4, and superlative performances from Koyamaichi laminated white steel.

Will there be a different presentation when the test is repeated, and will these results differ from blades used for planing?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th May 2011 03:47 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

15th May 2011, 10:51 AM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2007

- Location

- vic clayton

- Posts

- 1,042

thanks derek nice comparison test

Some people are like slinkies - not really good for anything, but they

bring a smile to your face when pushed down the stairs .

-

15th May 2011, 11:45 AM #3

plane addict

plane addict

- Join Date

- Oct 2010

- Location

- melbourne

- Posts

- 93

hey derek where u buy ur magnifying glass? i need one for real.

-

15th May 2011, 07:22 PM #4

Senior Member

Senior Member

- Join Date

- Feb 2009

- Location

- Esperance,Western Australia

- Posts

- 192

G day Derek

Thanks for the reveiw I have been wondering as to the real effeciveness and edge holding ability of some of the newer steels. I am thankful to now have some Japanesse chisels as they are a well balanced chisel and faired well in your reveiw.

Cheers Gerry

-

15th May 2011, 07:42 PM #5

We all appreciate the time that you take over your reviews Derek. It is great to read the results of the comparisons, and your critiques of hand tools in general. I think I have read just about everything that you have published here, and I would like to express my thanks for your efforts.

It is always interesting and often inspirational.

The forum is all the richer for it.

Keep it up

SG

.... some old things are lovely

.... some old things are lovely

Warm still with the life of forgotten men who made them ........................D.H. Lawrence

https://thevillagewoodworker.blogspot.com/

-

15th May 2011, 09:53 PM #6

Many thanks Gerry. Many thanks Tom.

I have a lot of fun writing the articles although I am never sure whether they will be as interesting for others. This one is the first in a series of three. I do hope that they inspire some discussion.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th May 2011, 09:54 PM #7

Hi Derek,

Great write-up. The Koyamaichi is very impressive against those specialist steels.

Cheers

Pops

-

15th May 2011, 10:31 PM #8

Derek

Very good analytical test. Thank you for taking the time and sharing the results.

I read in "AWR" many years ago a comparable test. Actually, your test was much more comprehensive. The "AWR" test involved 3 chisels and the task was to pare the end grain of radiata pine until a dull edge was observed.

The chisels included were a pre WW2 model, a Japanese chisel and a modern chisel such as Stanley. I can't recall the brands and a cursory glance at my back issues has failed to locate the article.

Interestingly the modern chisel paired about 10mm, the Japanese chisel 25mm and the ancient chisel 38mm. Please don't hold me to the exact figures. It has been a long time and ordinarily I can't remember what I did yesterday. If I turn up the article or somebody else knows the detail I stand to be corrected.

I remember they referred to "pre-nuclear steel" with regard to the old chisel and commented it may be superior because it included less recycled material. I don't know the validity of that comment.

Also, not all chisels are created equal even amongst similar styles. Some Japanese chisels will be better than other Japanese chisels for example.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

17th May 2011, 06:04 PM #9

Hi Derek,

Thanks for doing these tests. When you read product catalogs the manufacturer always makes their choice of steel seem the best option which doesn't help the buyer decide what suits them best.

I assume the x-axis on your steel chart shows wear resistance increase as the value of x increases (i.e the CPM 10V having the greatest wear resistance of the steels shown).

As the CPM 10V does not seem to be the best performer in your test I also assume that what your results show... hard steels chip and soft steels wear-out (am I reading this correctly?)

If my assumption above is correct then are you able to show which steels are the chippers and which ones are the wearers (it is hard for me to judge from just one photo of each) or am I over-simplifying things? My assumption would be that the most suitable chisel steel for use an jarrah (your test wood) would be the steel that sits in the middle of these two types.

Regards,

Chris

-

17th May 2011, 06:32 PM #10

Hi Chris

You are on track.

Based on the current evidence of the edges folding, rather than chipping, I would assume that the PM steels were actually too soft and we should be trying them in higher hardness ranges if they are to be used for paring after chopping. I think that the ideal edge is one that gets as close to chipping but does not do so (too much work to repair), perhaps shows just micro-fractures. These PM edges instead folded (which ensures the edge will be dull), with the M4 the closest to the "ideal".

This appears especially the case with the 10V, certainly with the 3V and least with the M4.

What I want to next do is assess these chisel steels in a test of paring. PM steels, especially 3V and M4, are potentially excellent choices for plane blades. Paring and planing ... both are about abrasion resistance ... for which these steels are expected to best suited (rather than impact resistance, which was poorish here).

So I will do the paring test, and it is likely that we shall see the results reversed.

Choosing steel for blades is always a compromise of strengths and weaknesses in regard to the target. Assessments like these, while quite amateurish, are real world and hopefully provide a window into their potential.

Note to self: must get an A2 chisel into this battery of steels. Anyone close with an A2 LN to loan me?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Lapping chisel and plane blade backs - a few tips

By rsser in forum SHARPENINGReplies: 83Last Post: 14th November 2010, 10:44 AM -

sharpening Blade or chisel in bush!!

By haosiliu235 in forum WOODWORK - GENERALReplies: 5Last Post: 14th October 2008, 07:42 PM -

Help on a rotary chisel blade

By artman in forum GENERAL & SMALL MACHINERYReplies: 7Last Post: 22nd December 2007, 06:57 PM -

Blade/Chisel Honing Guides

By Markw in forum SHARPENINGReplies: 18Last Post: 15th June 2004, 11:18 AM

Reply With Quote

Reply With Quote