Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 33

-

23rd November 2006, 08:13 PM #1

How can a waterstone be flatterned with water any faster ?

How can a waterstone be flatterned with water any faster ?

The concensus seems to be that its faster to flattern stones with water. I say its actually slower. I think flatterning them dry is the way to go. Less mucking about. I don't mind being wrong, but I've yet to see evidence that its slower.

Maybe I've got my wires crossed. Thinking about different things....I don't know.

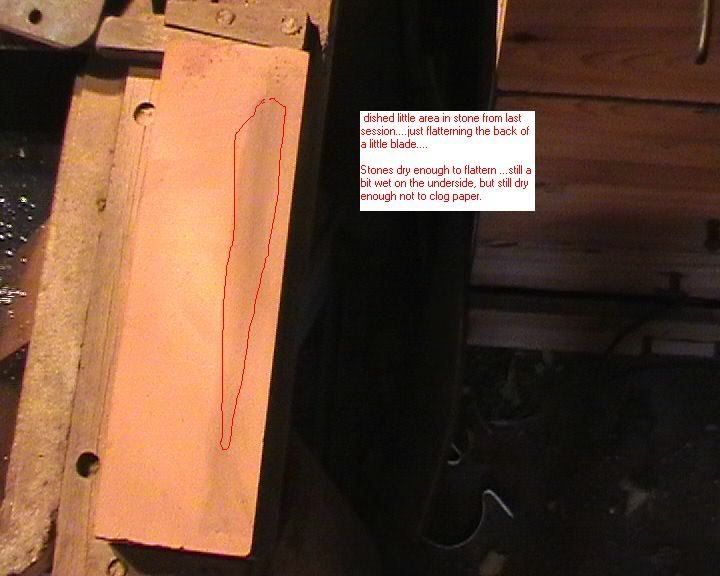

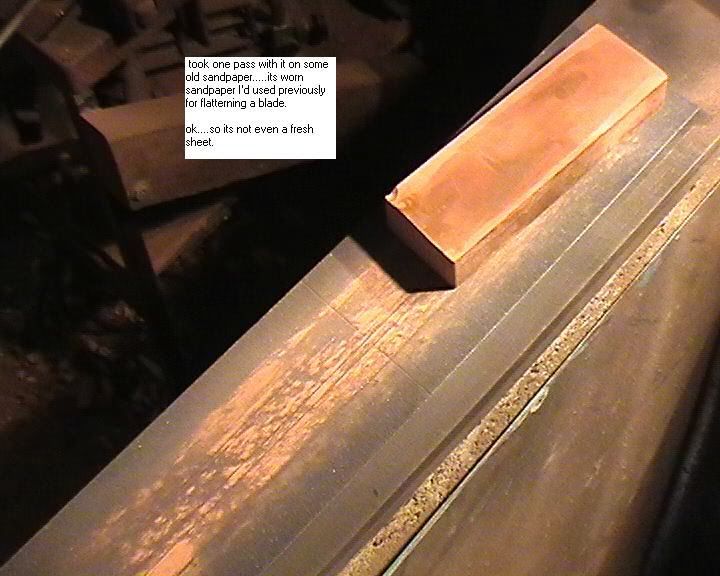

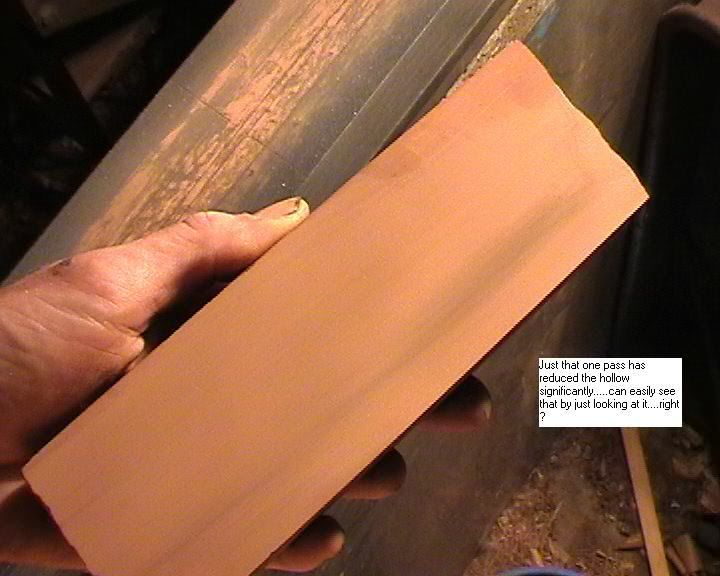

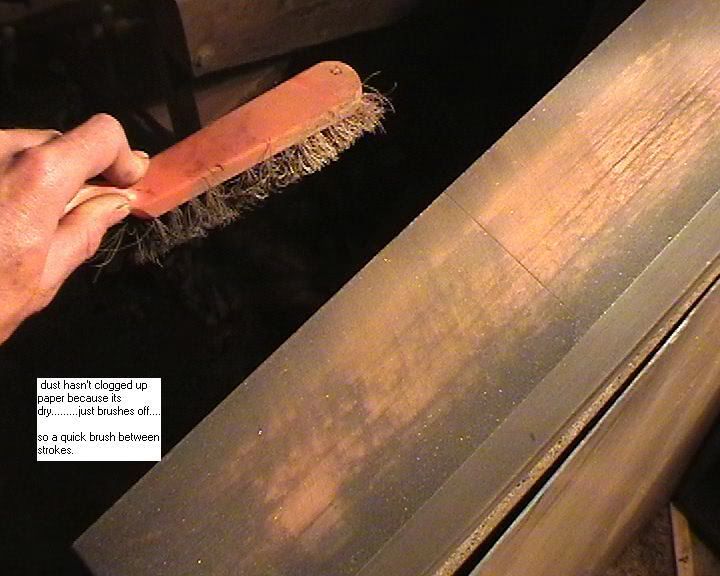

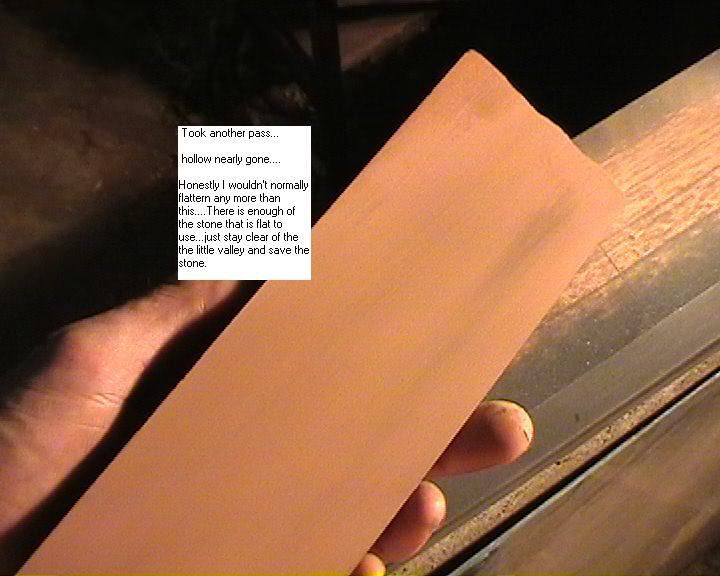

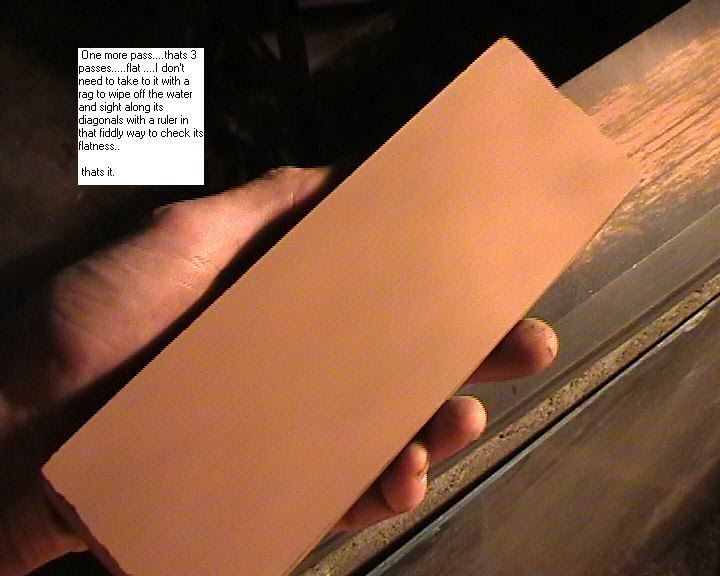

took a series of photos flatterning a stone this arvo to try resolve this. Tell me how this can be improved on ..

in this example....just 3 straight passes...2 bush strokes...dead flat.....How many seconds do you think that took ? .... Can a wet grit flattern a stone any faster ?

Reakon, should try and take advantage of dry flatterning anyway you can.

-

23rd November 2006 08:13 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

23rd November 2006, 08:35 PM #2

What do you call your Hobby Horse? :confused:

-

23rd November 2006, 08:35 PM #3

AR,

Just tried this with my 6000, thats out of water at the moment, and dry.

It was quite out of flat. I used a fresh piece of paper (120 grit)

I have to say, it was faster than doing it wet, just a few strokes, worked a treat.

Thanks for sharing.

-

23rd November 2006, 10:52 PM #4

Soft stone huh?

Wait until you get something a little harder/tougher to flatten.

Me, a couple drops of water to hold the silicon carbide grit on the flattening plate, scrub scrub and do all the stones at once. Wash off the crud and it's all done.

Then again, I mostly use a big King #1,000, another slightly finer stone, a much finer stone and a Shapton #180.

The stones I don't know the grade of are very likely ceramic and they are extremely hard. Sandpaper doesn't do anything to them, except teach frustration and make dead sandpaper.

If I am freshing up some stones, then I do use running water and rub the stones against each other.

(BTW, Jake there is a thing called 'silicosis' which is what you get from breathing in stuff like clay and fine sand. Guess what the water stone is made form? Clay and abrasive... :eek: )

-

23rd November 2006, 11:10 PM #5

Ta Underused. Glad I'm not the only one.

What you talking about Craig ?

ok.....even when done dry ? Most, I would feel, have regular king like stones.... sounds like you have more experience with harder stones than me Schtoo. But I'm not talking about those unusual cases. I'm talking about flatterning the stones that most of us use.

until when ? .....when it 'looks' or 'feels' good enough ? .....the problem I have with that is, it doesn't sound like a certain flatness to me....bench plane blades probably fine.....but rebate/dado etc blades relie on flat blade...

:eek: Really ! ...is it that bad....since there's just so much of it floating in the air when I'm flatterning those stones! Better not go to the beach with the kids anymore....or work with flour.....or sweep the floor.....or concrete stuff.....or use any powered machine without a big dust collector. Actually, uno, I'm having trouble breathing now !

-

23rd November 2006, 11:28 PM #6

The thing is, that the softer stones dish as soon as you get slurry on the stone. Not much, but it's there. When I sharpen something, I will have 3 stones wet. The big king and the two hard ones. The king dishes pretty quick, so the coarser hard stone takes off the high spots in about, oh, 3 seconds.

Do that every minute or so of sharpening. Keeps the big stone flat for longer, keeps it cutting fast, clean and no dust. The hard stones don't need much attention, but they get it anyway.

The SiC grit works on everything. Oilstones, water stones and ceramic stones. Fast and effective. Cheap too since a largish jar of grit costs about 5$ and the plate is nothing special, just a flat bit of steel.

Silicosis, have a read. Scared myself reading that.

I'm not saying that how you make your stones flat is not working right, just that I don't do it that way and probably never will.

I do have a sink where I sharpen though, makes things a lot easier.

-

23rd November 2006, 11:53 PM #7

I like that SiC grit idea...ta. If it works that well. So sounds like it works really well for flatterning broader bodies of steel as well ?....thats where I may have a use for it.

Still don't understand how one can relie on flatterning stones with others. Be too much to worry about for me.....uno, is the coarse stone flat enough ? cause if its not, it'll transfer to the softer stones etc...

.How can you be shore that you've flatterned the stone in 3 seconds if the stones wet ? .....when its wet you can't see the high spots well ( well I can't )

Thanks for the link on Silicosis..... honestly I can't read it. Just seems like yet another thing to worry about, amongst the other hundreds of ways of kicking the bucket. I can't be worried about about a little dust from sweeping away a bit of grit. uno Have a good weekend eh. One day to go.

Have a good weekend eh. One day to go.

-

24th November 2006, 12:09 AM #8

3 stones.

If they all rub each other flat, then they are flat. End of story.

Since the middle usually ends up dished, you twist the faces together, rubbing down the ends first.

Anyway, I don't have any concerns about them being flat because they are flat.

Sic works for almost anything. Very well for stones, works ok on steel, but hardened steel tends to crush the grit up pretty quick. It does work, but it gets messy fast.

-

24th November 2006, 01:33 AM #9

Hi Jake

Every time I have attempted to flatten my King stones in a dry state I find that the abrasive medium becomes loaded and then will not abrade any further.

One of the advantages of flattening wet stones is that the water will carry away the residue of flattening. That is the way waterstones work - the clay binds the grit and releases fresh grit as the top surface is abraded. Adding more water softens the clay and permits faster abrading. Conversely, if you want to take a (say) 6000 grit stone to a higher level, then use it dry. This will not allow the grit to escape, crush what remains, and imitate a higher grit.

A second point of issue is a strategy I learned from a DVD of David Charlesworth. Before flattening a stone he will draw a grid in pencil over its surface. This enables one to gauge if the stone is flattened evenly, that is, if there are any high or low spots remaining. How does one otherwise tell if the stone is flat?

Second last point. I use 220 grit drywall/plaster board mesh (from Bunnings). The advantage of this is that the "mess" drops through the mesh. I only fix the mesh at one end so that I can lift the other end to wipe away the "mess" as needed. The mesh is very abrasive and works very quickly.

Last point. I use 1x800, 1x1200, and 1x8000 stones. I touch them up (i.e. flatten them) at the end of each stone. There is never a time when they will be dry.

Regards from Perth

Derek

-

24th November 2006, 07:31 AM #10

righto, so you take a ruler to them often......cause you can't actually watch the stones wear flat without a ruler (thats what I'm talking about...its a slower process) ...so many ways of people doing it. I don't think I'd ever get a hard coarse stone, only because I'd leave that sort of work to the grinder and adhered sandpaper.

Ta. nice to know.

-

24th November 2006, 07:47 AM #11

Ah's a gonna git mah sayelf wun o these here puppies, y'all. Kinda sorts ever thang don't it?

http://www.leevalley.com/wood/page.a...072,43071&ap=1The only way to get rid of a [Domino] temptation is to yield to it. Oscar Wilde

.....so go4it people!

-

24th November 2006, 07:52 AM #12

Hi Derek. Thanks for posting.

I don't get that at all. Don't you feel you can brush it away either ?

I really don't want to get in an arguement with you uno. .... sure thats how grit washes away....but it abrades slower with water.....I've done both plenty. Dry flatterning (with a brush) is rapid. Faster. I mean the evidence is there every time I flattern a stone. Been doing it a while too.

I swear I'm not one of the few who thinks this way either.....I've got a book somewhere here by a Ian Kirby.....and another by Finck (I think) who both make mention of how flatterning dry is faster. Words to the effect -> 'try and do it that way if possible'. ....

if you want proof, I can dig the books out and photo those pages and stick em up here if you like.

By looking at it ..... if you make straight passes on grit dry....you can see the dishes in the stone lap away(unlike when its wet)......On a completely dry stone the contrast is very clear..........for a long time, in my paranoid way, I'd check that my lapped stone was indeed flat after seeing the vally dissappear with a ruler.......but it always is ! I don't need to bother anymore (which is great...less stuffing about).

..... if you make straight passes on grit dry....you can see the dishes in the stone lap away(unlike when its wet)......On a completely dry stone the contrast is very clear..........for a long time, in my paranoid way, I'd check that my lapped stone was indeed flat after seeing the vally dissappear with a ruler.......but it always is ! I don't need to bother anymore (which is great...less stuffing about).

So, you see, why would I fiddle about drawing lines on my stones ?

I agree. I think that stuffs great. Far better than lapping with wet sandpaper. I think its good for when you have to lap wet. But its still slower than lapping dry.

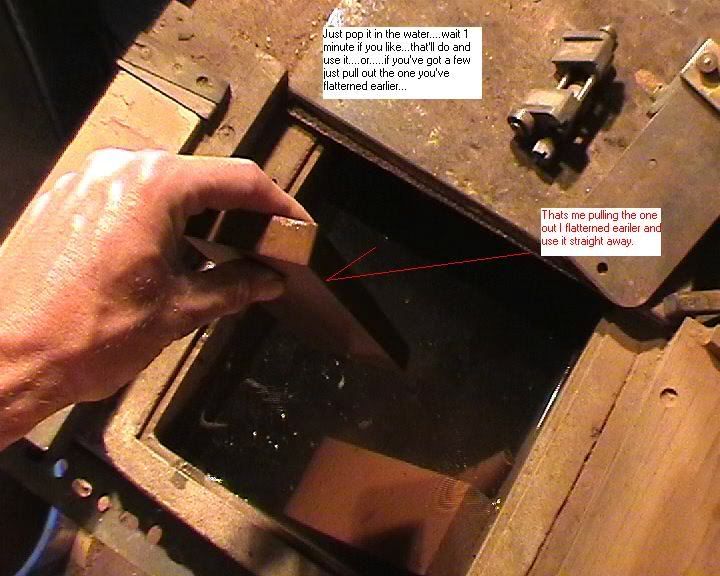

Yes they wouldn't be dry enough if you've only got one of each stone (still would be sometime when your not sharpening everyday)...... Thats why you get more than one. (except 8000's pricy things. would get multiple 6000's instead)... which is the crux of this dry technique......and when all your stones are too wet for lapping dry.....you lap with that mesh.....see ?

pricy things. would get multiple 6000's instead)... which is the crux of this dry technique......and when all your stones are too wet for lapping dry.....you lap with that mesh.....see ?

-

24th November 2006, 08:35 AM #13

He's talking about your last thread on this topic. But I guess there are probably a few people here now who didn't witness it last time.What you talking about Craig ?

He's talking about your last thread on this topic. But I guess there are probably a few people here now who didn't witness it last time.What you talking about Craig ?

-

24th November 2006, 02:00 PM #14

Senior Member

Senior Member

- Join Date

- Jan 2004

- Location

- Melbourne

- Posts

- 466

Flattening

Flattening

So long as it works does it really matter?

-

24th November 2006, 05:22 PM #15

Interesting thread!

Jake, I think Derek was referring to sharpening with a dry stone having the same effect as using a higher grit - not flattening.

If I were to flatten my stones when dry I'd have to wait a while, then flatten them. If I flatten them while wet I don't have to wait at all, so even if the process is marginally slower I don't lose time waiting.

Just to add something of value, if you squiggle a pencil over the stone it makes it easier to tell when you finally get it flat.

cheers.

Similar Threads

-

Gas hot water heaters

By Bob Willson in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 28Last Post: 29th March 2005, 12:16 PM

Reply With Quote

Reply With Quote