Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 39

-

21st January 2006, 08:13 PM #1

I fixed the snipe problems in my thicknesser !

I fixed the snipe problems in my thicknesser !

Hello, got some more discoverys to share.

I spent a couple hours today on my thicknesser. It had a snipe problem. Uno, how the last couple of inches of the pass are cut at a slightly deeper depth. Like I've drawn in this photo...Seems to happen mostly at end of pass. Sometimes it happens at start, though rarely for me.

I've solved the problem I think. And I thought, cause my thicknesser is of a generic kind, others may benifit also from what I've discovered. Be plenty of machines out there like mine for sure.

I've got a cheap Ryobi model from Bunnings, of all places. Its had a snipe problem since I bought it, and I had learned to live with it, by simply organising my stock so the snipe would sit in offcuts....But, its really a PIA...sometimes you don't have enough timber to cut it out. eg. I've been thicknessing some old wooden planes lately. I definetly don't want any snipe left on any part of something like that....especially 2" of it !

I'm convinced snipe is the consequence of a few problems. But I'll detail just a couple of what I think are the more important ones, I learn't of today. With pictures ! Gee wizz

First problem : I noticed there to be an unacceptable amount of flex in the infeed and outfeed tables, but also, when timber is sitting on both rollers simultaneously, it wasn't touching the bed under the cutter head ! ie. beds not flat. So, I cut some thick laminated chipboard to width to fit as the new bed. (The left overs from kitchen sink cuttouts are great for this) Also good I found, because the laminate is hard wearing and sliiiipry, to reduce friction and wood jam.

It turned out the rollers were sitting too high. So, I removed them by unscrewing the side screws of both sides of infeed and outfeed tables, which also caused the plates to drift freely.

Then I drilled through from the underside of the plates and screwed the loose plates up tight into my new chipwood bed. Both infeed and outfeed sides. Like in this picture

Then tightened up those side screws I loosened earlier. And there was my new fixed bed. Longer than what I had with the origional infeed/outfeed tables and most importantly..no flex. So, I tested it,,,and it reduced snipe only a little... Still was obviously there.

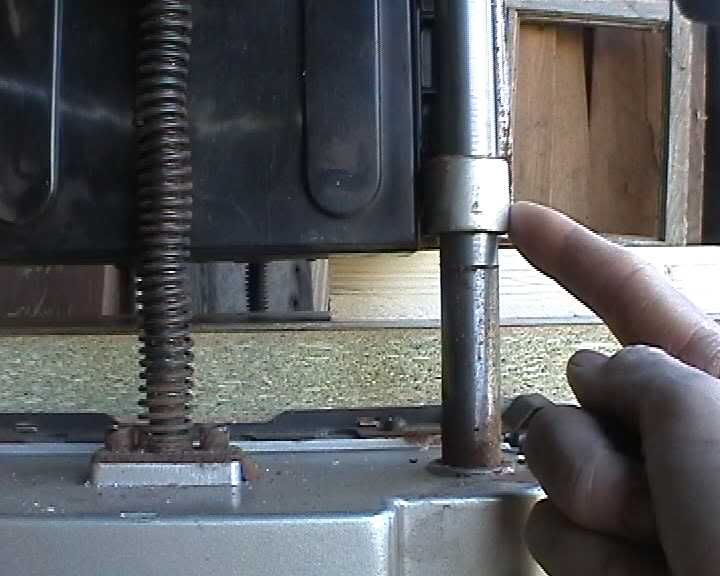

So, after removing the thicknessers housing and scratching my head for a while, and realised what the problem was...Look at this. What does it resemble to you ?

To me, it resembles a single screw bench vise. Uno, screw in the middle with a supporting bar either side. And single screw bench vises RAKE, right? . And there's reason for this thicknesser to rake as well, I think, just like a bench vise. Look at this picture, which shows the cutter head, and on either side a roller. Each roller is heavily spring loaded to keep the wood flat on the bed. Theres your torque.

I started the thicknesser up, with the housing still off and fed a piece through and this is what happened.

First the wood hit the first roller. The heavy pressure from the first roller actually caused the whole assembly to jolt ever so slightly up at this point here on the bar. I could actually see it LIFT, raking the entire assembly. Lifted maybe 1/2mm.

Then the wood hit the second roller. This side of the assembly lifted on the bar as well.

Not much. Barely noticeable, but I did see a little lift.

Now the important picture. Just as the wood leaves the first roller, that side of the assembly DROPPED that 1/2mm it lifted before, and co-incidently the first roller and the cutter head are 2" apart (about the same amount of snipe one gets). So, a poor design was the cause of the snipe, which made the assembly rake, which drops the cutter head about 1/2mm as the wood leaves the first roller. Bugger. (but I'm getting excited, cause I finally know the problem) And I'd say, many other machines with a similar design have this problem.

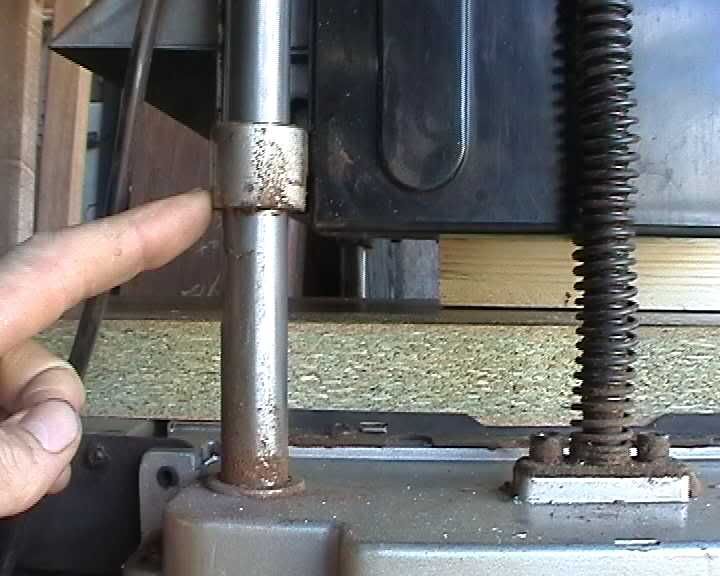

The only way I found to completely fix this problem was to install thumbscrews to stop this raking. I drilled/tapped a hole through the slieve, for each of the 4 support bars, and screwed in a thumbscrew for each, so I could lock the assembly completely so it wouldn't rake. Thats 4 thumbscrews. Tried it and ....it worked !!! (deserves 3 esclamation points, I think) . No snipe what so ever. Good feeling.

You don't have to loosen and tighten those thumbscrews every pass you make. I only bother about it near the end when approaching your final dimension. ie. Snipe doesn't bother me till then.

The other problem is that, to get to the knumbscrews you have to keep the housing permanently off. Which doesn't bother me. It may bother some though, cause you can't see the depth measurement slidey thing on the housing anymore. I never used it anyway. The other thing is , you don't have those little rollers on the housing anymore to convienently place your timber......but I'd give them up in a flash anyday, to have a thicknesser with no snipe ! ....So, this is how it'll look for now on.

Thanks, if you found the patience to read through all that Seeya.

Last edited by Wood Butcher; 27th September 2007 at 10:37 PM. Reason: Fixing Pictures

-

21st January 2006 08:13 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

21st January 2006, 08:21 PM #2

Great job and rundown

looks like a good solution to a common problem. and you can also get the swmbo to do some thicknessing when she chucks some clothes in the washer

looks like a good solution to a common problem. and you can also get the swmbo to do some thicknessing when she chucks some clothes in the washer Blowin in the Wind

Blowin in the Wind

-

21st January 2006, 08:46 PM #3

good stuff jake, I had little improvement in snipe when I tried attaching a new table, the reason is probably what you have mentioned.

Very interesting though, It probably means that a thicknesser like the dewalt should have little or no spine???

Also one concern about tapping the sleeves (at least in my old gmc thicknesser) is that they are very flimsy and getting a crack in them would be game over.

regards

MariosYou can never have enough planes, that is why Mr Stanley invented the 1/2s

-

21st January 2006, 09:05 PM #4

Jake,my man

Well done, I have the same model as yourself and have noticed the snipe, but only on the final 15 mm.

I think I'll continue to live with it and allow an extra 25mm on the timber.

It must have been really pissing you off to engender all this research and remedial action.Bodgy

"Is it not enough simply to be able to appreciate the beauty of the garden without it being necessary to believe that there are faeries at the bottom of it? " Douglas Adams

-

21st January 2006, 09:19 PM #5

No dickhead

No dickhead Originally Posted by redwood

Originally Posted by redwood

That's how he thicknesses and dries his timber in one pass. Who needs to buy expensive kiln dried timber, hey Jake? Cheers

Cheers

Jim

"I see dumb peope!"

-

21st January 2006, 09:29 PM #6

Jake

I'vegot a 40 yr old 12 inch x4 inch thicknesser that has received more than its fair share of swearing. But when I see how these modern pieces of shyte are made I appreciate mine. My one has the cutter head fixed and the bed rises and falls.Also the infeed and outfeed rollers are sprung independently of the cutter head.I'm thinking this is good now!!!!(worth 4exclamation marks).

Thankyou formaking me appreciate what I have.

Trouble is replacement knives are almost impossible to buy and when you can find someone to make a special order they want $330 for a set of three.

So just when I'd decided to buy a ryobi for about the cost of a set of knives you point out this design fault. I don't know whether to kick you or kiss you.:confused: :confused: :confused:

Keep up the good work of keeping us informed. (I think)Cheers

Jim

"I see dumb peope!"

-

21st January 2006, 09:42 PM #7

nice work tripper, get some magents (1 x 1 x 6 inches) a good way to get the cutters at the right height.

excellent work on the post - exactly what this forum is about.Zed

-

22nd January 2006, 12:22 AM #8

Jeeze...

I'm impressed.

Couple of things though, get something on the top of those posts to try and lock it all back together. Also, running screws into those posts might scuff them up, and make them unhappy.

I'd say split the sleeve bearings and then a clamp over the top, but then you would have to lock them up before each cut, a right PITA.

And the scary part? My 3 day old Makita snipes on the infeed, and prolly because of this exact same problem, even though it's better built and brand new.

Jake, what say we just go back to handplanes, huh? No freakin snipe in them...

-

22nd January 2006, 10:38 AM #9

Fantastic post - very well done !!!!

I have just purchased exactly the same model of thicknesser last week, and was reading up all the old threads to see how people had dealt with the snipe problem. One surprise (off topic slightly) - the Ryobi AP13AK now has a proper built-in plastic dust collection port with an outlet to suit a shop vac, also a plastic adapter to take this up to 4". Looks like I won't need any of the home-made dust collection adaptations after all.

From what you have achieved, I wonder if the lack of post locking in the standard product is responsible for MOST of the snipe, i.e. no amount of stuffing around with infeed/outfeed extensions is going to make that much difference.

I'll have to get into the guts of mine to see what method I can come up with to clamp the four posts.

I'm also kicking myself, 'cos I just noticed that Carbatec are getting rid of their remaining Delta thicknessers at a greatly reduced price ($599 I think). Not sure which stores still have them, as I didn't see any in Sydney last time I was there. There might be a problem getting spares/support for the Delta in the future, but guess what? It has a post locking mechanism built-in to prevent snipe........

A lesson learned, but thanks for saving me so much time trying to work out what was going on with the Ryobi model !

-

22nd January 2006, 10:41 AM #10

Schtoo - that was why I didn't get the Makita. Apart from being better put together, I couldn't see that it had any actual performance benefits over the cheap generic Ryobi/GMC models. At least with the DeWalt I could see some tangible benefits (3 blades, 2 speeds,etc.) to justify the huge price difference.

Hereabouts, the Makita costs over A$1000. The Ryobi model can be had for around a third of this !!

-

22nd January 2006, 10:50 AM #11

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2005

- Location

- Lake Macquarie

- Posts

- 864

well done mate, you should contact ryobi and they may well take this into account in a new model one day...

Hurry, slowly

-

22nd January 2006, 10:55 AM #12

I'm already thinking.......if the cutter head couldn't rise up as the wood hits the roller, then it wouldn't come down again as it exits.

Sooooo, some kinda cam lock clamp attached to the post above the uppermost collar, slide it down onto the collar and lock it to secure everything. A cam lock compression sorta device would avoid damaging the actual posts themselves. Wonder if that is what the Delta has? Wonder if the posts are the same diameter? Wonder if they are available as 'spares'....

(walks off to shed muttering to himself.....a dangerous combination

)

)

-

22nd January 2006, 11:05 AM #13

n hello to you 2

n hello to you 2 Originally Posted by Caliban

Originally Posted by Caliban

Blowin in the Wind

Blowin in the Wind

-

22nd January 2006, 12:39 PM #14

I can already see one way to implement the 'rippermod' without having the sides of the machine off.

Make up 4 sliding collars (just need to find the right size pipe) with locking screws, to sit above the top 4 post clamps of the machine. There is enough space to have the thumbscrews facing the insides of the machine, in which case no need to have all the covers off.

This also has the benefit that you are making and threading a new part, rather than hacking into the machine itself. Any minor stuff ups are therefore easily fixed (just reach for another piece of pipe....), and the machine can be returned to standard by just sliding the new clamps back off the posts.

-

22nd January 2006, 08:23 PM #15

Love your diagnostic work jake, your effort will help many of us who have the same or similar machines and suffer the same frustrating problem.

The guys have mentioned making collars which attach to the vertical posts. I agree this is a very good option as there is no chance of accidently causing unrepairable damage to the machine, so what about using regular hose clamps??? I dare say it would be pretty easy to pick four up the right size. They would apply even pressure around the post and can be moved quite quickly when adjusting the height.

Just my two cents worth.

Cheers, Evan

Similar Threads

-

Thicknesser Problems

By bennylaird in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 19Last Post: 16th October 2007, 01:53 PM -

thicknesser snipe (i hate it)

By sean_in_ireland in forum WOODWORK - GENERALReplies: 10Last Post: 27th August 2005, 02:30 PM -

Thicknesser Feeding Problems

By Rob from Kew in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 14Last Post: 5th April 2005, 07:47 PM -

Carbatec CTJ 340 thicknesser

By chook in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 1Last Post: 23rd December 2004, 08:26 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote