Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 16

Thread: Jointer guards for old machines.

-

24th August 2015, 05:28 AM #1

Jointer guards for old machines.

Jointer guards for old machines.

Hi all just posting some pics of the parallel action guards I make for my jointers.

The smaller is on my current machine a Wadkin Bursgreen 9 inch, the larger a Barker 12 inch machine which I sold off.There is also a couple for Wadkin 16 inch machines mates have.

The steel one on the Barker is an original.

I'm vague on who made it might have been Beale from Victoria in the 60s.

The Al on mine is just cut from some large dia tube and tig welded.

They automatically rise and fall for jointing faces and move in and out for edging.

I probably have a few of the large springs in the junk pile and kept a few from the kids old trampoline which would also work if any body wants to make themselves one.

H.Jimcracks for the rich and/or wealthy. (aka GKB '88)

-

24th August 2015 05:28 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

24th August 2015, 10:30 AM #2

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,794

You could replace all those complex levers and springs with a simple "heavy door closing mechanism".

These mechanisms have adjustable closure rates and being compact are less likely to get in the way.

This is one I made for my 16" jointer. The old wooden one is just behind it.

-

24th August 2015, 12:44 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Bob,

Love the use of the door mechanism , but if you have a look at the version Henry has, there are some excellent design features that are not apparent at first glance, not only in the mechanism, but in the guard design, perhaps a video demo in the future Henry??

, but if you have a look at the version Henry has, there are some excellent design features that are not apparent at first glance, not only in the mechanism, but in the guard design, perhaps a video demo in the future Henry??

It will arc away from the fence, but it will also stay against the fence and lift up, it is a very cool design, which takes a lot of thought out of the setup, and most importantly means the guard is covering the blade as often and as much as it can.

Cheers,

Camo

-

24th August 2015, 12:57 PM #4

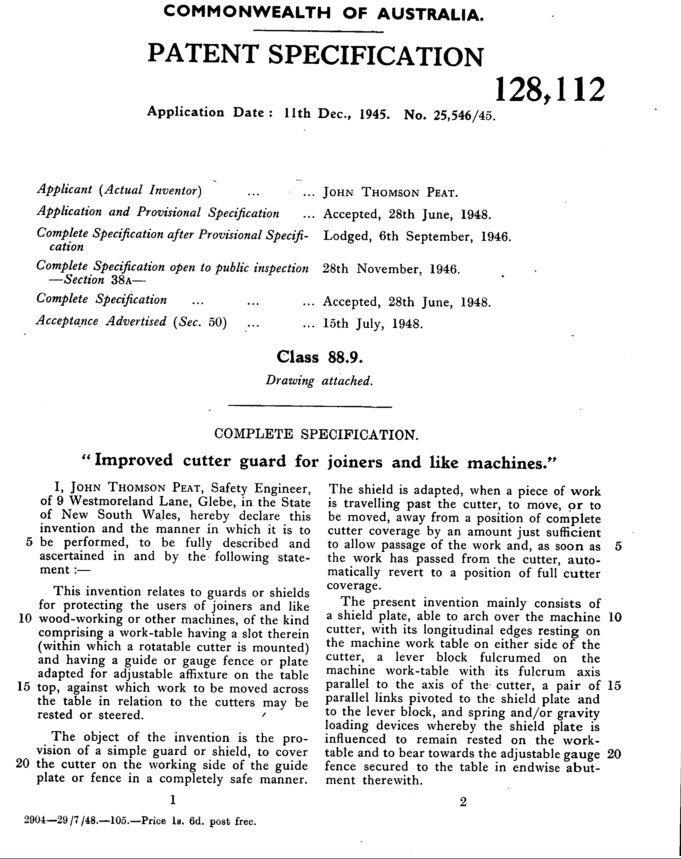

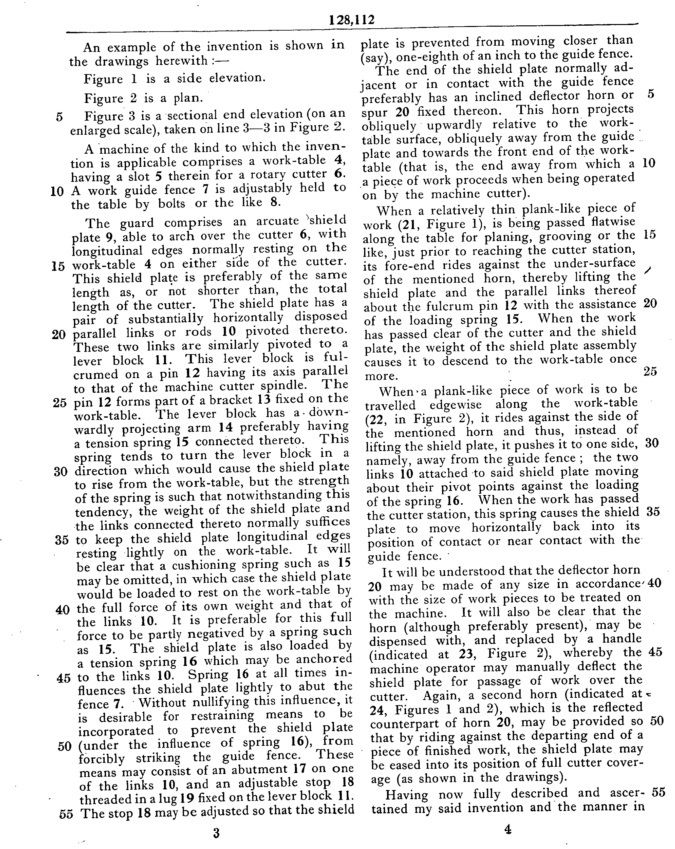

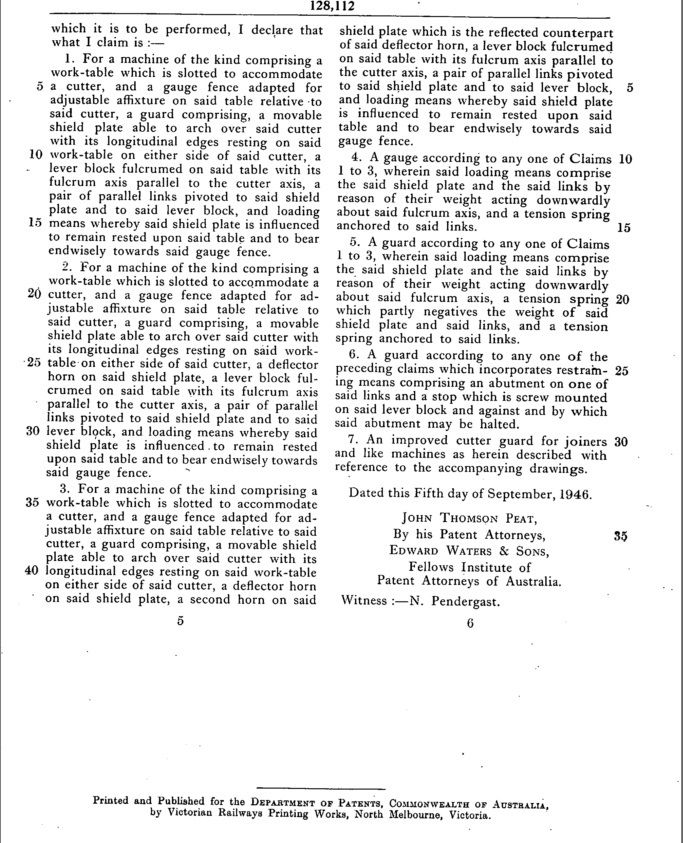

Henry,

this was on one I had.

Sydney maker J. T. Peat Pty Ltd

Maybe I had it adjusted incorrectly, but I found it slow to move. It appeared the heavy steel would lag behind where I absolutely wanted it to be instantaneously.

A lighter one in alloy would improve that for certain.

Cheers,

Peter

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

24th August 2015, 01:38 PM #5

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,794

I agree a guard than always covers the top of the blade has it's merits.

One problem with a guard that lifts is this hides the top of the blade while creating side gaps between the guard and the blade for a finger or two to slip into.

I always reckon that it's better to either completely cover blades

OR

Expose the blades completely so they can be seen.

Half covered blades can lead to probs as one of the members of our mens shed found when one of his fingers slipped into the gap created by partially covered cutters.

Luckily for him he just got a nick off the top of his finger.

The "door closer" style does stay very firmly up against the wood and down on the infeed table so it does not expose the blades.

Either way using a rule that say no body part shall cross the blade is a good one to stick to

The guard is made of 6mm thick aluminium plate and 25 x 3 mm SH aluminium tube with 5/16 Brass screws so if it does make contact with the cutters it will not ruin the

There is a short steel stub at the end of the arm where the guard connects to the door closing mechanism.

Underneath the guard there is a strip of HDPE that slides on the end of the infeed table and supports the guard.

It is possible to lean hard quite down onto the top of the guard and it will not contact the cutters

What I prefer about this design is that does not get in the way on the out-feed side so you don't need to lean across it to maintain down pressure on the out-feed side.

This means less fatigue and thus less likely to make mistakes.

-

24th August 2015, 05:57 PM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Bob,

I should apologies as I have assumed you had missed the differences in design between yours and the one Henry showed, I must admit, the first time I saw it, it took a bit to see it all.

How does yours function Bob, I'm seeing a very well constructed 'Pork Chop' design, and I mean that as a complement (always mindful of how words can be interpreted differently when using a forum setting), as some of those 'Pork Chops' are useless. Yours isn't mounted, so perhaps I'm missing something in the design?

(always mindful of how words can be interpreted differently when using a forum setting), as some of those 'Pork Chops' are useless. Yours isn't mounted, so perhaps I'm missing something in the design?

If it is, my concern with these designs is when putting through wide stock, I think wide thin stock is probably where you are most vulnerable. The only thing then between my hands and the blade, when on the infeed side, is this board. I've not seen a 'Pork Chop' design that would close quick enough to protect me, in that situation (in fact I've seen some that haven't been adjusted right and practically don't close at all), obviously when the board passes through under normal operation your hands should be on the outfeed side and my hand definitely shouldn't ride the board over the blades, but to me, normal operation is not where you need the guard. Safe operating procedure protects the hands during normal operation, the guard is there to protect you when you stuff up, or something goes horribly wrong.

I think every design has it's flaws, especially if they are not operating as they should. I do know one thing, if yours does work similar to a 'Pork Chop', I have a feeling I would feel more confident using yours, than most I have seen .

.

Cheers,

Camo

-

24th August 2015, 08:30 PM #7

Senior Member

Senior Member

- Join Date

- Feb 2012

- Location

- Willunga

- Posts

- 141

For those who don't have a TIG welder. My Robland Combination machine is fitted with something similar. The fence fits on the RH side in this picture. The original plastic guard was broken when I got it, this replacement is made from a piece of thick walled 4" pipe, cut into segments and rejoined with glue and brass screws. All the guards on this machine are yellow and I have stayed with it. I would never put my hands over the cutter block but this guard does keep it well covered and stays out of the way.

Regards

Ian

IMG_0262.jpg

-

24th August 2015, 09:00 PM #8

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,794

Thanks Camoz

Yep I agree the pork chop design still has problems.

Most porch chop guards are flimsy POS and use spring mechanisms that are too weak and liable to break easily.

The door closer I used on the yellow pork chop has a very powerful spring and an pneumatic adjust to determine the closure rate.

I reduced the pneumatic adjust so that the spring is able to act as fast as possible and it fair slams the chop into the fence once the back end of the wood goes past the guard.

The spring pressure is so powerful it contributes to the guard holding the wood up against the fence and you do have to give it a fair push to get it to open up.

This can be a PITA with odd shaped pieces.

This one is not suitable for small stock but one might ask why one would be working small stock on a 16" jointer.

My 10" thicknesser has a fixed guard that is adjusted to the height or width of the wood.

I don't like it because that means a gap between the guard and the jointer bed and I have been meaning to replace it with a door closer guard.

There are now door closers around that close allow the when when they want the pneumatic adjust to kick in and how hard they want it to act.

This means the door can most of the way closes very rapidly and then the pneumatic adjust kicks in only at the end of the closure stroke

One that I saw allows the pneumatic adjust to kick in within a couple of mm of the door closed position.

-

25th August 2015, 04:33 AM #9

-

25th August 2015, 08:57 AM #10

stellar job H! Not tried one like that. Made a back guard that works good though.

added a spring loaded tip to the bridge.

All tools can be used as hammers

All tools can be used as hammers

-

25th August 2015, 11:42 AM #11

Henry,

It is an early Wolfie.

A road trip with Matty....a few years ago.

Deeply countersunk brass screws up underneath on the hand pusher. The jarrah cleat underneath is rebated in and glued.

I was working out if I could make plane handle blanks cheap enough for sale years ago...no I can't...but I have quite a few lying around still.

Funny you should mention the hands over the blade.

Last week a bloke I met recently came with some draw fronts he had made in Turpentine (SP??) and I was instructing him how I was taught to run stuff over the buzzer.

He'd been at a local wood joinery with the last lot of draw fronts a few years ago, and the bloke just grabbed that kind of thing and ran with both hands palm down over the cutter.

I asked what happens when the board shoots out the back?

Cheers,

Peter<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

25th August 2015, 12:48 PM #12

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

My father-in-law does exactly the same thing, drives me nuts

. Knowing he won't listen to me, I decided to show him some how to videos, when he was searching youtube one day.....stupid me, do you think I could find one that didn't have the supposed instructor doing exactly the same thing, even some with their thumb down the side of the board on the trailing hand as they go over the blade

. Knowing he won't listen to me, I decided to show him some how to videos, when he was searching youtube one day.....stupid me, do you think I could find one that didn't have the supposed instructor doing exactly the same thing, even some with their thumb down the side of the board on the trailing hand as they go over the blade . I'm sure I do a lot of things wrong in the workshop too.

. I'm sure I do a lot of things wrong in the workshop too.

cheers,

Camo

-

25th August 2015, 01:16 PM #13

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

-

25th August 2015, 01:53 PM #14

Camo,

the wolfie had a clam-shell head, and I wasn't all that keen on the guard...so when a later one from them with a gib head came up for almost no money I jumped on it and sold the old one.

I'm more than happy with the later one.

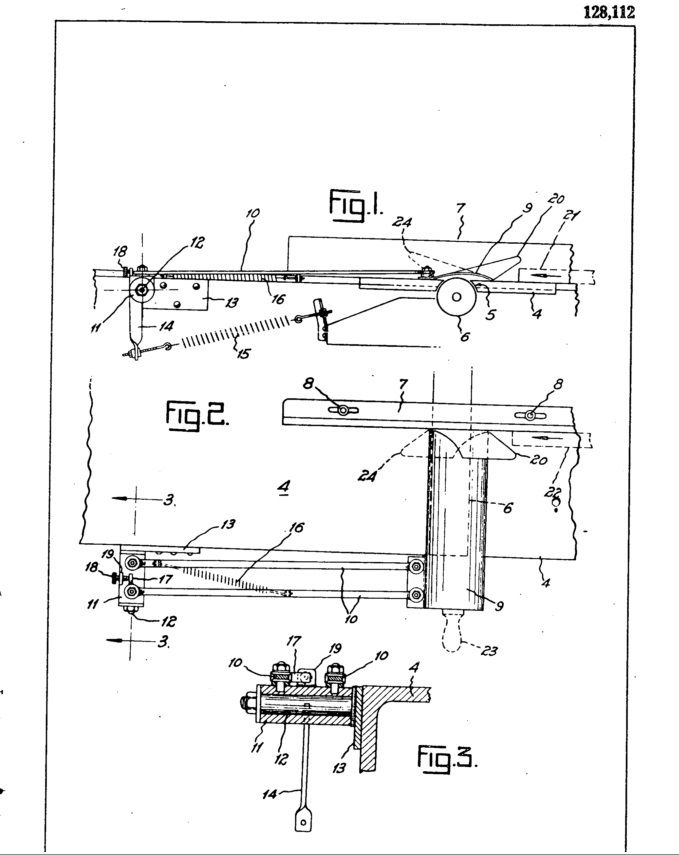

It seems that the parallel type guard was available much earlier in the states.

A UK subject in US patented it in Dec 1914, 30 years earlier...!

"To all whom it may concern Be it known that I, EMERALD E. JONES, a subject of the King of Great Britain, and a resident of the city of Chicago, county of Cook, and State of Illinois, have invented certain new and` useful Improvements in Guards for Woodworking-Machines, of which the following is a specification. "

https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US1119612.pdf

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

25th August 2015, 03:41 PM #15

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Similar Threads

-

home made safety guards

By coffenup in forum WOODTURNING - GENERALReplies: 18Last Post: 7th July 2013, 10:16 PM -

Douglas Shaper original guards

By jhovel in forum METALWORK FORUMReplies: 21Last Post: 8th July 2012, 10:09 AM -

Hercus AR Belt Guards

By Geoff123 in forum THE HERCUS AREAReplies: 2Last Post: 16th November 2011, 07:46 AM -

blade guards fences and other safety matters

By soundman in forum HAND TOOLS - POWEREDReplies: 11Last Post: 21st May 2002, 08:31 AM

Likes:

Likes:

Reply With Quote

Reply With Quote