Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 24

Thread: Twin vice

-

14th October 2011, 04:39 AM #1

Twin vice

Twin vice

I'm thinking of making a twin screw vice using two standard vices (eg Dawn No 7, Record No 52, etc) and one long wooden chop? Any ideas on this - either on making it or using it?

Screwing up in new ways every day Cheers

Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

14th October 2011 04:39 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

14th October 2011, 07:24 AM #2

How about connecting the vices with sprockets and a chain? If you mounted the sprockets on the ends of the screws under the bench, the bench would largely shield the chain from debris.

.

I know you believe you understand what you think I wrote, but I'm not sure you realize that what you just read is not what I meant.

Regards, Woodwould.

-

14th October 2011, 07:41 AM #3

Basically a homemade version of this?

Lie-Nielsen Toolworks USA | Chain Drive Vise

-

14th October 2011, 08:06 AM #4

Not sure how succesful that would be. You would have to wind both handles at the same time unless you removed the guide rods from both vices. If you did that you might as well use a couple of big tail vice screws.

Thinking about it, even with the guide rods removed the moving jaw would make it too inflexible to operate smoothly.

Have a look at Claw Hama's massive twin screw vice. It works pretty well.

-

14th October 2011, 09:32 AM #5

Thanks for the replies.

I wasn't thinking of trying to synchronise the two vices so I only had to turn one handle to move both screws. I thought that if I used two vices with quick releases, I could use the quickreleases to move the long clamping face (I'm hoping to get about 60cm between the centres) until it grabbed the workpiece and then I could snug the face up using the screws independently.

My Record 52 has some slack in its guides so I thought that if I got another in a similar state there would be enough wiggle room that the works wouldn't jam up entirely.

An alternative would be to saw through the clamping face after it is installed, but I was worried about racking in that case.Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

14th October 2011, 10:26 AM #6

Jeremy - don't see why your idea wouldn't work - I'm sure I have seen it done omewhere, but can't remember where.

A 'refinement' of your idea might be to mount the two vises at the desired spacing, with a common long back jaw insert, but 'regular' front inserts. Then just slip in a long jaw when you need to clamp long boards between them. That way you would still be able to use at least one of the vises independantly, which might be handy....

I think I'm with NCArcher - although it's tempting to save a bit by using the vise you already have, it would probably be much simpler to use a couple of tail-vise screws (which aren't all that expensive, depending where you get them). The guide bars on your Dawn are going to be unnecessary in such a setup, & more of a nuisance. The disadvantage is losing the quick-release feature, but depending on what you use the vise for most, possibly not that big a deal. I made my own front vise with a tail-vise screw & water pipe guides, & occasionally wish I could disengage the screw for quick openings & closings, but most of the things I put in that vise are relatively thin, so there isn't a lot of screwing involved.

involved.

Cheers,IW

-

14th October 2011, 02:07 PM #7

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- bilpin

- Posts

- 3,567

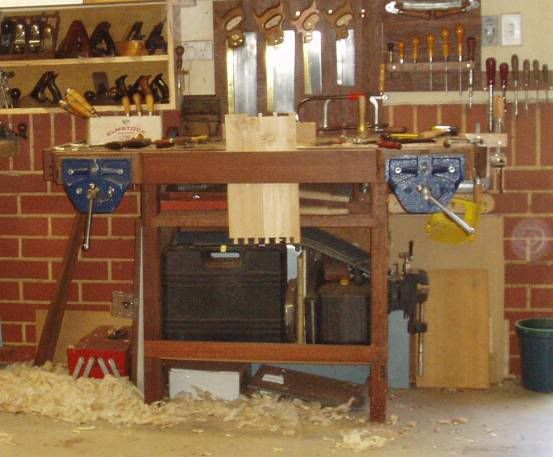

Knocked up a new bench recently, mounted two record vices, one at each end , on the same side of the bench. Find it very handy for long work, also as a pair of clamps in tandem with bench dogs.A long inverted L chop or slipper makes the two vices into one long vice. My thigh will be glad when I eventually remember the second vice is there.

-

14th October 2011, 02:58 PM #8

Rusty

Any chance of some pictures?

Thanks

Screwing up in new ways every day Cheers

Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

14th October 2011, 04:26 PM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Aug 2011

- Location

- bilpin

- Posts

- 3,567

Did you want pictures of the bench or my thigh? The thigh I can do for a reasonable price. Unfortunately the bench and its vices are out on site at the moment and I am not, due to a recent eye operation.

-

14th October 2011, 05:23 PM #10

Hi Jeremy

I did this about 10 years ago, especially for dovetailing. All that was needed was a long sturdy board spanned between the two vises ...

This was then replaced by the "$5 dovetail vise" ...

Now I use a Moxon vise: http://www.inthewoodshop.com/ShopMad...etailVise.html

There is a new bench in preparation, Leg vise and tail vise, but no double screw face vise, except for the Moxon.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

14th October 2011, 10:26 PM #11

Why not just make two screws as we've been discussing and use them?

regards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

15th October 2011, 06:50 AM #12

Good question, Nick

Some answers (not all of them adequate )

)

- Overactive imagination

- I have one vice already installed and another lying around somewhere in the shed, so why not try to use them to achieve my desired outcome

- Moxon style vices are trendy - I rebel against the trend

- I know I can install a vice, I am not confident that I can make two screws

I may well end up doing what everyone else is doing, but I just want to explore the alternatives before I follow the herd.Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

- Overactive imagination

-

15th October 2011, 10:56 AM #13

Hi Jeremy

The first question to answer is "how do I use my bench?". I came to the same conclusions as Chris Schwarz, who has spent a lot of time researching this area: jointing, facing, and sawing/dovetailing. Planing and Sawing/dovetailing ideally are done at different benches with different heights for ease of work.

With the use of a Moxon, which raises as well as holds the work, not only do you use one bench more effectively, but the work-holding method can change. A double screw vise is replaced with a single screw Leg Vise for edge jointing as this vise both clamps just where it is required and it takes up less bench space.

Anyway, that is my reasoning, and the reason I no longer see a low, double-screw face vise to be ideal. Fortunately it comes at a time when I actually need and will dedicate time to building a new bench (my existing one is 20 years old and very small).

I have a wooden screw for the leg vise, which I will design and build, while for the end vise I have purchased a BenchCraft wagon vise.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th October 2011, 04:34 PM #14

Good Morning Jeremy

Contrary to the other views expressed, I have difficulty in imaging how your proposed vise could be operated easily.

With two separate quick release vise mechanisms would you not have to use both hands to release both mechanisms simultaneously for quick sliding? And hold you work piece with your third hand? Or am I missing something.

Or perhaps something like Derek's initial set-up. Two Dawn/Record vises closely spaced would operate similar to a twin screw vise. Or they could be widely spaced as per Derek.

But Derek went to a "$5 dovetail vise", then to a Moxon.

As always, it is horses for courses.

Fair Winds

Graeme

-

15th October 2011, 04:49 PM #15

Hi GraemeWith two separate quick release vise mechanisms would you not have to use both hands to release both mechanisms simultaneously for quick sliding? And hold you work piece with your third hand? Or am I missing something.

Hi GraemeWith two separate quick release vise mechanisms would you not have to use both hands to release both mechanisms simultaneously for quick sliding? And hold you work piece with your third hand? Or am I missing something.

The way to use a twin-vise is to ..

1. adjust one side to the depth/thickness of the board, then leave it at this setting forever!

2. Only open and close the other side when inserting and removing the same thickness board.

In other words, it is essentially used as-if it has one screw. Imagine a leg vise on its side (indeed, a long LV twin screw vise - which adjusts both sides together - could make the perfect leg vise!!).

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Twin Screw Vice Fitting?

By Scally in forum THE WORK BENCHReplies: 19Last Post: 24th August 2009, 11:20 PM -

Twin Screw bench vice

By Shedhand in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 2Last Post: 29th April 2006, 08:15 PM -

Tail vice/End vice

By silentC in forum POLLSReplies: 17Last Post: 30th November 2005, 08:19 AM -

VERITAS twin screw tail vice

By steve 54 in forum WOODWORK - GENERALReplies: 5Last Post: 25th October 2004, 10:53 PM

Reply With Quote

Reply With Quote