Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 74 of 74

Thread: A type of lazy susan

-

27th September 2007, 06:14 PM #61

Thanks above for the encouragement,.

Yes Skew the centre box at the present time is removeable and I think your suggestion sounds a good idea. It would have to have a fixed base in addition to the box base.

I'm still struggling how I am going to glue up the 6 lids with inclines(whcih look super at the moment in the raw) I am thinking of cutting up some polystrene to shape inside the container and using that as a template for the lids to lay on and somehow get a stick up.

More help appreciated.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

27th September 2007 06:14 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

27th September 2007, 07:30 PM #62

I've been doing some thinking about suitable jigs for this. Without too much luck.

But if you're drilling a hole in the middle you could trim a little bit off each point before the glue up. Then make a jig which is basically just a coach bolt through a sheet of MDF. Stack washers on the coachbolt until you have the incline you want, rest the pieces in position around it and then put a washer/nut on top.

Then you could use a band clamp or several hose-clamps around the outside of the lid to squeeze everything together, the nut/washer should stop the middle from trying to lift up as pressure goes on.

Does that make sense? (I could draw a pic or two if you want...)

- Andy Mc

-

27th September 2007, 07:50 PM #63

I got what you mean Skew re the bolt and washers.

The outer bottom edge I can most probably squeeze up with temp. fitted wood battens .

We've got very cold northerly winds here in the UK at the moment, so things will wait for better gluing conditions.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th October 2007, 05:26 AM #64

It’s a week and I’m back, I can’t believe where that went. Some of you know I’ve been jigging around and today the first dry day I got lumbered with planting around 500 spring bulbs. Did it the easy way, dug a trench and poured them in.

So this evening I purloined a new tool for my workshop, the electric bread knife and then cut some polystyrene to shape and fitted inside the seventh box orifice.

Dropped the lid on top and got a reasonable fit.

Then decided to make a ply template to glue the triangular pieces too.

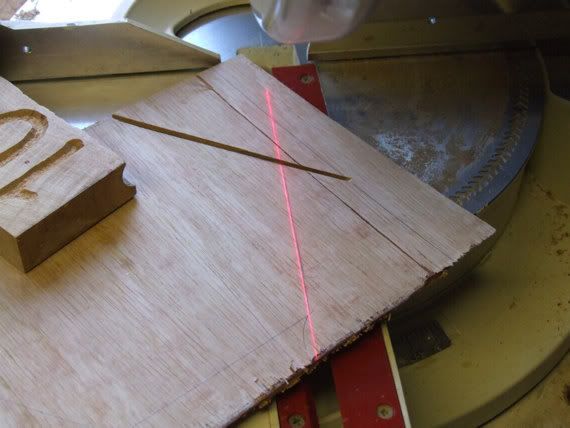

Handy things laser lines on SCMS saws.

The ply fitted OK.

So glued pieces down and edges of each piece to each other.

Going back later this evening to bring it into the kitchen for the evening to keep it nice and warm and also keeping my fingers crossed.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th October 2007, 10:32 AM #65

Box Challenge 2011 - Check out the amazing Boxes!

Box Challenge 2011 - Check out the amazing Boxes!

Twist One - Wooden Hinge/Latch/Catch/Handle

Twist Two - Found Object

Twist Three - Anything Goes

-

4th October 2007, 12:43 PM #66

-

6th October 2007, 06:20 PM #67

Pleased to report back that things are working out OK and stress is coming down.

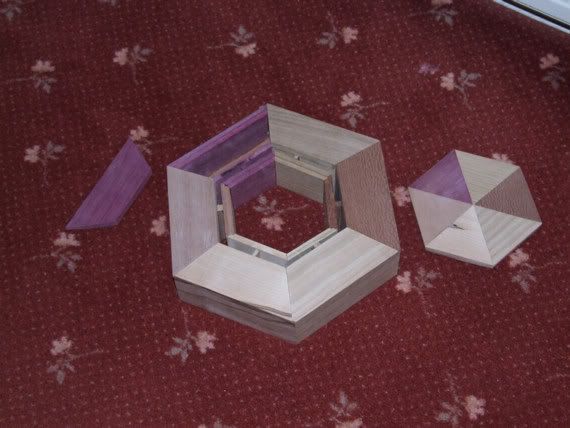

The centre lid was glued up couple of days ago and yesterday I got down to cleaning it up. This was necessary because the centre box portions have a rise up to the centre point (that match outer ring, more luck than judgement) and that created small gaps at each joint section, however some thin slivers and other sections, just glue and sawdust has put things right. (for me anyway)

The inner box was secured to the outer ring with matching vertical small spacers and a base closure plate has to be made together with a system of raising lids.

Couple of quick pics to show progress todate.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

10th October 2007, 04:16 AM #68

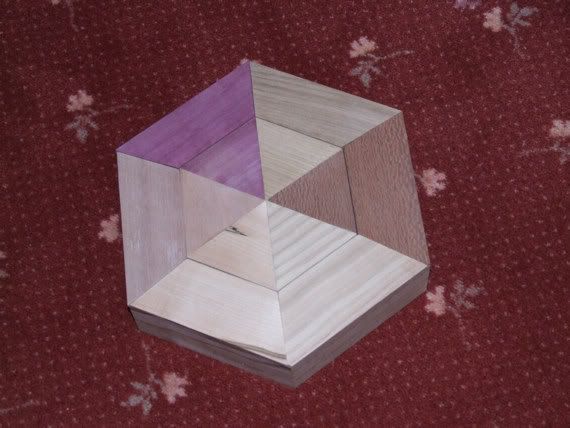

I am pleased to say the lazy susan comprising seven boxes has now been finished. I would confess that it has been a struggle at times and I would most probably only anticipate a C grade if it was a school project.

Some of the 60% angles are not perfect but have been cobbled together with slightly compensating adjustments.

However I have found it a resting place in our home and it might get used for my daily pocket money allowance to stop me overspending each day, or could even be used as a weekly tablet allowance .

That now makes the third item awaiting a finish to be applied, shellac and wax.

Thanks for watching and those helpful suggestions. some were very much appreciated.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

10th October 2007, 02:28 PM #69

Been fun following this thread John

, look forward to seeing a finish on it

Cheers

, look forward to seeing a finish on it

Cheers

DJ

ADMIN

-

10th October 2007, 03:48 PM #70

John

I think you are too harsh on yourself. It definitely passes the "blind Freddy" test - ie Blind Freddy running for his life in a fire won't notice the defect, so you shouldn't. Anyone who goes around checking that every angle is 60 degrees should just step back 3 paces and look at the effect and see that it looks "right", so it is right.

So how are you going to finish it?Cheers

Jeremy

If it were done when 'tis done, then 'twere well it were done quickly

-

10th October 2007, 05:54 PM #71

It may have a fault or two in execution, but they're more than made up for in originality and degree of difficulty. (I don't care what anyone else says: compound mitres are not fun.)

Thanks for posting the WIP: it's been an interesting read. And you've definitely given me some ideas for my merry-go-round box.

- Andy Mc

-

12th October 2007, 10:16 AM #72

Overall a fascinating journey. The result, great! Well done!

-

13th October 2007, 06:06 PM #73

Pleased to say the lazy susan style box has been waxed and now found a resting place!

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

13th October 2007, 06:36 PM #74

Looks great John, the colours have really popped out now that you have a finish on it

Cheers

DJ

ADMIN

Similar Threads

-

Sturdee's Lazy Susan

By Sturdee in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 4Last Post: 16th April 2007, 04:26 AM -

lazy susan finally finished

By paul collins in forum WOODWORK PICSReplies: 3Last Post: 9th January 2007, 03:31 PM -

Lazy Susan Finishing

By Happy Chappy in forum WOODTURNING - GENERALReplies: 10Last Post: 18th July 2006, 04:28 PM -

Lazy Susan

By stu_g18 in forum WOODWORK - GENERALReplies: 11Last Post: 24th May 2005, 08:41 PM -

lazy susan

By Agro in forum TIMBERReplies: 2Last Post: 28th February 2005, 07:39 PM

Reply With Quote

Reply With Quote