Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 676 to 690 of 722

Thread: Saw sharpening files 101

-

8th August 2013, 08:05 PM #676

Their coming soon....

Their coming soon....

I'll be starting to post the results shortly. They'll be broken down into separate posts for easier digestion, and also because of the limit on pics per post.

I'll let the results sit here for a day or two before posting them elsewhere so that I can iron out any bugs, tpyos etc.

-

8th August 2013 08:05 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th August 2013, 08:11 PM #677

Saw file test results

Saw file test results

Firstly, a huge thank you to the three testers (Peter, Mark and Ian) who gave a great deal of their time to make this possible. Ian in particular spent additional time marking out the saw plate scraps so that the other two could just hook straight into filing teeth.

PREAMBLE

The three testers all have different perspectives, and that is why I thought they would be a great mix.

Ian Wilkie (IanW) is virtually a professional Saw Maker (could easily be if he chose to – whenever he puts a batch up for sale they sell out within about 30 minutes, and he ends up with more backorders than he put out for sale). He has formed from scratch I’d guess thousands of teeth over the years, and sharpened countless more. Ian didn’t have to do a great deal of research – he has done so much saw filing that it is intuitive, and he has quite a pedigree when it comes to fine woodworking, going back at least a couple of previous generations of very talented chaps. His preference for gullets on finer toothed saws is for less-round and like everybody else, laments the passing of proper Saw Files. In contrast to the other two testers however, he is not a huge fan of the taper, and can take it or leave it (although we might just see about that when proper tapers make their long-awaited return).

Peter Evans (heavansabove) is a serious amateur woodworker and as a very active member of The Traditional Tools Group, he is no stranger to saw sharpening and rehabbing. He likes a fairly sharp gullet in his saws, and is a big fan of the proper taper file. Peter has contributed a great deal of research to this project, including vital information such as the 1942 Nicholson Catalogue which revealed that both Taper and Parallel files were popular choices at that time. Peter also uncovered various other aspects of saw files, such as how the edges of the files are formed before they are cut (they are flattened with a file – not rounded over or “radiused”, and the edges are cut before the faces are).

Mark Aylward (Claw Hama) is a professional woodworker and sculptor. He has been classically trained in the art of filing twice, in two apprenticeships, and so knows his way around a file. He had a strong influence from his father and grandfather who were both professionally involved with timber. It was Mark who was able to describe the function of the taper in a file, and this was a pivotal moment in this project. He also defined why the corners of the file are toothed beyond where the faces are toothed at the toe. We have had long verbal and written discussions throughout this project to date, and that has been of enormous value in bringing it to this point. He also spent many hours researched and digging for the truth. This is a man who likes his gullets a little bit more curved than the other two testers, and I have a feeling that this is because of the size and type of timber that he has worked with – often large slabs of nasty Aussie hardwood with big tooth saws, where a sharp gullet can cause a fracture, and possibly allow for less efficient ejection of dust than a curved gullet might. Mark can probably rightly claim to be the world’s biggest fan of the proper taper file!

The files selected for testing were primarily aimed at those used for saws of 10 ppi and finer. Certain brands, such as Nicholson “Taper” files and Vallorbe Needle files were not included because their current reputation for quality (or a serious lack of) is so well known as to not be worth determining. Some brands were not as well represented as others, and this was largely due to the deep suspicion that many of them come from the same factories and provenance. There was only a certain amount of files that could be purchased and have time from the testers devoted to them.

For larger toothed saws, although there were new teeth formed in saw plate samples, the main purpose was to determine the suitability of the files for sharpening. There is scope for two types of file for larger teeth – a coarser file for rough forming and rapid metal removal, to be followed by a finer file for final shaping and sharpening of the teeth. Finer teeth are much quicker to form and a fine tooth file should do this quickly and efficiently. Therefore the files aimed at these saws were required to be able to do both functions effectively.

Researching has involved many people both here and abroad. Countless websites have been studied and numerous historical publications have been read. However, in all the tens of thousands of words that have been read, there has been no mention whatsoever of the purpose of the taper, or what widths the various file sizes and categories have their edges ground to. This would indicate that the taper and edges were taken for granted as much as a file has to be made of steel and have teeth cut in it to function (although there is at least some information around on those last two aspects). To all those who have assisted in the research – my great thanks.

Citric Acid sharpening was performed on 6 files, and a duplicate untreated file was also included. The testers were asked to pay particular attention to the differences between each file in the various pairs. One of these pairs was the Japanese file, another was a French made Liogier, and the other four pairs were of Indian origin.

In three of the Indian pairs, the acid treated file was a poorer performer, and in one of them it was marginally better, but both files in this pair performed extremely poorly. The acid treated files broke more teeth than the other file almost universally

.

In the Japanese pair the acid treated file scored better, but this would appear to be due to better corners on this file, rather than any improvement made by the acid bath.

In the French pair the untreated file scored marginally better than the treated file. Tester C scored the acid file better, but that was because it had a better shaped corner(the specific corner that he used), rather than any improvement made by the acid.

We can assume quite safely that the steel used in the Indian files is inferior to the Japanese and French steel (that’s the only reason they are being produced in India – too get a cheap file). It would appear that acid treatment of lesser quality steel has a greater detrimental impact on it than on better steel. The Japanese acid file scored better than its counterpart (but because of the corner, not the treatment) and the French acid file only scored marginally lower than its mate. In other words, in files of quality steel, the acid didn’t cause it to be a disaster, but equally, it did not aid performance.

In short, the Citric Acid treatment contributed nothing positive whatsoever, and seems to have a very bad effect on lesser quality steel. After I had treated the files I noticed that they felt much “grabbier” (sharper) to the skin, and under a loupe of 8x magnification the treated files looked MUCH sharper and cleaner. Encouraged as I was by this I kept the caveat that this must translate to improved performance, and it did not – quite the opposite.

This leads me to wonder about those who claim that their old files are much improved after an acid bath – are they just being fooled by the grabbiness on their skin (it is a very significant difference in feel)? I wonder if they have ever done any empirical comparisons, because the evidence from this test would appear to be incontrovertible, although the sample was fairly small to make a bold statement, I suppose. Six-nil is pretty convincing though. Perhaps the effect is less noticeable with Engineer’s files where there is not so much concentrated stress on the corners.

Whatever it is, there seems to be no point in putting saw files into an acid bath – it won’t improve the performance of a new file, quite the opposite in fact. For an old file – well, they are worn down and there is no substitute for missing steel! There may be some short term temporary benefit with an old file made from good steel, but that was not the object of this testing. One thing is absolute – the height of the teeth is reduced as the file wears down, and acid treatment can only make them shorter still, certainly not longer.

TESTING CRITERIA

All the labels and logos were ground off the files, and they were each given a unique number. In this way the tests were done “blind”, although files from the sub-continent just look like they are from there, so possibly not hard to work them out. The files were only tested at one tooth pitch, and we were trying to determine the maximum number ppi (i.e. finest tooth) that the files were capable of. Right at the outset, it was noted that none of the 4” DEST files would be capable of 16-19 ppi, and so they were moved into 15.5 ppi. Whilst one of them performed ok at 15.5 the real point is that they are all failures because they are not fit for purpose at their intended tooth pitch range of 15-19ppi.

The Liogier Needle file was supposed to be tested at 19 ppi, but there was a little confusion there, and it was run at 15.5. No matter, being a 3 Square Needle it should be quite capable of finer than 15.5 ppi.

SCORING

<6.5 – FAIL

6.5 to 7.4 – BEWARE, you may or may not get a good one, might be inconsistent within the file itself.

7.5 to 7.9 – PASSABLE, should be ok

8 to 8.9 – GOOD FILE, buy it

9 plus – DOESN’T MATTER, no file scored over 8.7

Now i just have to load the pics ontp Photobucket - back soon.

-

8th August 2013, 08:37 PM #678

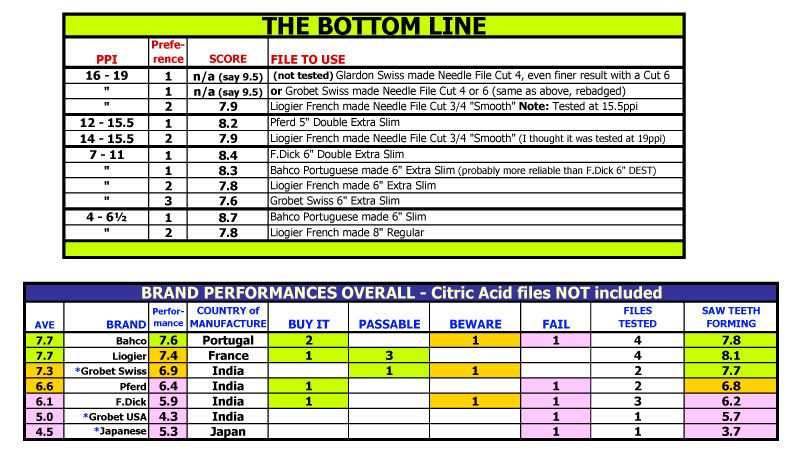

AND SO TO THE RESULTS

I’ll commence with the bottom line, which is a chart of which files can be used for the various ppi ranges, from those files that were tested.

As far as being able to just go out and buy files for any ppi saw from one trusted brand – FORGET IT! Liogier would be the safest bet here, with no failures, but we have previously known failures to have been delivered (suspect that there was a cockup with 4” ST being sent as 4” EST on one occasion).

BAHCO - The larger Bahco files performed very well, with two winners, but the 5” DEST failed (and I have read that many people complain of this with the smaller Bahcos). The Needle file, whilst it cut good teeth, looks like an expensive proposition due to durability issues. It is also a very short file at 140mm total length.

LIOGIER - Equal overall score to Bahco (actually 0.05 higher), with no failures, but plenty of room for improvement with consistency of edges, and of course the taper. As a brand, Liogier scored highest for the tooth shapes formed (the most important single factor), but was dragged back a bit by some rough action files. We know from previous experience that when a Liogier file is on its game, it is the Duck’s Nutz.

GROBET SWISS – only represented by two files that are “officially” from this brand, but Indian files overall were very well represented (by default). Pretty ordinary results, with no failures. Neither file gained a “BUY IT”, with one file managing to get a fourth preference.

PFERD - An enigma. One file was a clear winner, and one a clear loser. Balance that with the box of files (6” DEST) I purchased that had clearly seen a meltdown. Maybe just stay with the 5” DEST, and hope they are consistent.

F.DICK - Another enigma, probably due to poor quality control. 6” DEST actually scored the second highest overall of ALL files, but the brand was dragged right down by some other shockers.

GROBET USA – Like the G.Swiss, it had low representation (1) but in the company of plenty of fellow countrymen. A very poor result to be the last of the Indians….

Japanese - Not at all popular, and last behind the Indian contingent. Does Citric Acid help this file? Hard to say, but probably not.

GENERAL OBSERVATIONS

- Of the 10 files that make it to the recommended list, only 2 are from India, the rest are European.

- There are no 4” DEST files available that are fit for purpose.

- There are only a couple of files for use on 12 to 15.5 ppi saw

- There is a better number of files for 7 to 11 ppi

- <7 ppi should be no problem, but only two files tested for that range

- No file of any size had a correct taper, and it became even more apparent to two testers just how important the taper is (for constant pressure). The most experienced tester is not fussed about the taper, and that is consistent with all that has been discussed - experience will allow for a parallel file to be used, and perhaps even preferred (and let’s face it, these are all virtually parallel files)

-

8th August 2013, 08:59 PM #679

Amazing!

-

8th August 2013, 09:14 PM #680

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2009

- Location

- South Africa

- Posts

- 950

Well done, and thank you for the effort (and expense) you have gone to.

-

8th August 2013, 09:34 PM #681

TEST RESULT PICS CAN BE VIEWED HERE AT BETTER RESOLUTION (I hope) LINK TO PHOTOBUCKET

TEST RESULT PICS CAN BE VIEWED HERE AT BETTER RESOLUTION (I hope) LINK TO PHOTOBUCKET

TEST RESULT PICS CAN BE VIEWED HERE AT BETTER RESOLUTION (I hope)

LINK TO PHOTOBUCKET ALBUM.

-

8th August 2013, 10:49 PM #682

Wheeuw - monumental effort getting all those pics organised! The resolution is pretty good to me - brings back a few memories....

IW

IW

-

9th August 2013, 12:07 AM #683

Yes, well done Brett, what a mission to analyse all that info and post all those photos. And yes thanks Ian for setting up those saw plates, they were great.

Talk about blind testing I didn't realise or hear about the acid testing and I didn't even try and have a guess at the brands at best I new a couple were the same brand because a couple looked similar and performed in a similar way. The acid treatment certainly dropped the endurance of the files, usually you could feel the loose teeth roll through under the file after the first or second cut like rocks on a gravel road

at best I new a couple were the same brand because a couple looked similar and performed in a similar way. The acid treatment certainly dropped the endurance of the files, usually you could feel the loose teeth roll through under the file after the first or second cut like rocks on a gravel road I thought they had come out of a Corn Flakes box.

I thought they had come out of a Corn Flakes box.

The old straight or taper debate isn't really an issue as much as perhaps getting a consistent file be it parallel or tapered. The inconsistencey in files and even sides of files is the thing that makes it hard to file a regular tooth I think.

Gullet size, I don't really want to see it all that big but I do like to see a nice radius U not a V or especially a W .

.

At least all my saws are sharp now.

-

9th August 2013, 12:24 AM #684

-

9th August 2013, 12:45 AM #685

Btw, tomorrow I'll fix up some images of the Excel report (which has all the gory bits) into a PDF, Photoshop it into Jpegs and edit the posts so that everything is together, as it should be for easy digestion. For some reason a PDF turned into a Jpeg gives significantly better resolution than a screeshot into Paint and into a Jpeg. Go figure, but it's a lot more tedious work than a screenshot.

-

9th August 2013, 04:10 AM #686

-

9th August 2013, 09:01 AM #687

-

9th August 2013, 09:55 AM #688

So when are you going to dump this damning compendium of failure onto some file manufacturers?

top job all round.

...I'll just make the other bits smaller.

top job all round.

...I'll just make the other bits smaller.

-

9th August 2013, 09:58 AM #689

Yep - amen to what Claw said.

It was a fun project, but I felt under a bit of pressure. By and large, the testers' opinions were amazingly consistent (unlike the files! ), so that was a relief. The few outliers can mostly be attributed to the wildly different corners on some of those files. I was first cab off the rank, so I just picked up each file, shoved it into my filing guide, and went to work. It was only after I'd finished with it that I looked at the file closely, & that's when I noticed that a couple of times I had used what looked like the best corner on the file, and a couple of times what looked like the worst! One file in particular I thought was an utter dog, but Mark found his corner fine, liked the way it performed, & went on to do extra with it. He ended up giving it a double thumbs-up!

), so that was a relief. The few outliers can mostly be attributed to the wildly different corners on some of those files. I was first cab off the rank, so I just picked up each file, shoved it into my filing guide, and went to work. It was only after I'd finished with it that I looked at the file closely, & that's when I noticed that a couple of times I had used what looked like the best corner on the file, and a couple of times what looked like the worst! One file in particular I thought was an utter dog, but Mark found his corner fine, liked the way it performed, & went on to do extra with it. He ended up giving it a double thumbs-up!

The three testers have not discussed their results with each other at all, and we have only seen anyone else's results since Brett posted the collated results, so there were no biases from that direction. Our test can be criticised because we should have had multiple examples of each file scattered in there, but you've gotta draw the line somewhere - none of us had an entire week to devote to it. Based on my experience of saw files over the last 5 years of pretty heavy use, the test has certainly confirmed my whinge about inconsistency and inadequacy of corner sizes of files supposed to be ok for finer teeth, and excessive brittleness of many files. My take-home message is that I can get some decent saw files for saws with larger teeth (12 tpi and coarser), but it's slim pickings for fine-toothed saws. For the moment, I'll be sticking with the needle files for 15 tpi & above

The big surprise to me was that a couple of files cut teeth that I judged acceptable, but when I looked at their corners, I was amazed at how rough they looked. By and large, that wasn't the case, if the file cut roughly, the corners looked rough too, but the couple of outliers have left me head-scratching. How do those wretched corners function??

So, all good fun, now back to less serious business.......

Cheers,IW

-

9th August 2013, 10:12 AM #690

Similar Threads

-

Saw sharpening files

By Virgil in forum SHARPENINGReplies: 1Last Post: 4th October 2009, 02:31 PM -

Saw sharpening files

By Dan in forum SHARPENINGReplies: 0Last Post: 10th August 2007, 05:54 PM -

Sharpening Rasps & Files

By Robert34 in forum SHARPENINGReplies: 10Last Post: 7th June 2007, 10:04 PM -

Saw Sharpening Files and Jarrah

By Lumber Bunker in forum ANNOUNCEMENTSReplies: 0Last Post: 24th March 2007, 09:30 PM -

Saw sharpening files

By Arron in forum SHARPENINGReplies: 8Last Post: 15th January 2006, 05:06 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote